Description

Aperçu du produit

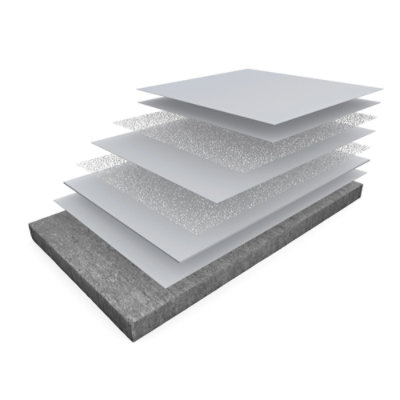

TerraFlex™ EC is a seamless, decorative cementitious urethane flooring system designed for high-traffic industrial and commercial spaces. It integrates a moisture-tolerant, self-leveling cementitious urethane mortar body coat with a decorative chip broadcast, finished with a chemical-, UV-, and wear-resistant polyurethane topcoat. The system offers exceptional durability, thermal cycling resistance, and a decorative finish, making it ideal for environments such as hospitals, schools, warehouses, and retail spaces where hygiene, safety, and aesthetics are critical.

Common Industrial Flooring Problems & Scenarios

Industrial and commercial floors face constant challenges that compromise safety, hygiene, and longevity. Common issues include:

Cracking & Damage: Heavy machinery and impact cause cracks in traditional concrete floors.

Dusting & Degradation: Untreated concrete generates dust, contaminating products and air quality.

Chemical Corrosion: Spills from oils, acids, solvents, and cleaning agents degrade floor surfaces.

Moisture & Mold: Water infiltration leads to mold growth, adhesion failure, and slab damage.

Poor Cleanability: Porous surfaces trap dirt, bacteria, and stains, increasing maintenance costs.

Slipperiness: Wet or polished floors pose slip hazards, risking employee safety.

Scenario Examples:

Food & Beverage Plants: Require non-porous, chemical-resistant floors that withstand frequent washdowns and sanitization.

Warehouses & Logistics Centers: Need ultra-durable, impact-resistant flooring to support heavy pallet jacks, forklifts, and high foot traffic.

Garages de stationnement : Demand weather-resistant, UV-stable, and aesthetically pleasing finishes that endure freeze-thaw cycles.

Healthcare & Schools: Prioritize hygienic, seamless, and easy-to-clean surfaces to maintain sterile environments.

TerraFlex™ EC: Solution & Key Features

TerraFlex™ EC addresses these challenges with a robust, multi-layer cementitious urethane system. Key features include:

Mechanical Durability

High Abrasion Resistance: Withstands heavy wheeled traffic with minimal wear.

Impact & Crack Resistance: Flexible urethane matrix absorbs impacts, preventing cracks from propagating.

Load-Bearing Strength: Supports sustained heavy static and dynamic loads without deformation.

Résistance aux produits chimiques et aux taches

Resists a wide range of chemicals including oils, greases, acids, alkalis, solvents, and sanitizers.

Non-porous surface prevents absorption, making spills easy to clean.

Seamless & Hygienic Finish

Joint-free design eliminates dirt and bacteria traps, simplifying cleaning and sanitization.

Meets USDA, FDA, and health department requirements for food-safe environments.

Safety & Slip Resistance

Available with optional anti-slip aggregates to achieve desired coefficient of friction (COF > 0.6 wet/dry).

Compliant with ANSI/B101.1 and ANSI A326.3 safety standards.

Thermal & Moisture Tolerance

Excellent thermal cycling resistance, suitable for environments with temperature fluctuations.

High moisture tolerance reduces risk of blistering or delamination on active slabs.

Aesthetic Versatility

Available in a wide range of standard and custom colors with macro or micro chip broadcasts.

Gloss, satin, or matte finishes to match design requirements.

Fast Installation & Low VOC

Rapid cure times minimize facility downtime.

Low or zero-VOC formulations improve indoor air quality and comply with environmental regulations.

Spécifications techniques et données de performance

| Propriété | Méthode d'essai | Valeur |

|---|---|---|

| System Thickness | Nominal | 3/16 inch (4.8 mm) |

| Résistance à la compression | ASTM D-695 | 16,000 psi |

| Résistance à la traction | ASTM D-638 | 3 700 psi |

| Résistance à la flexion | ASTM D-790 | 4,700 psi |

| Dureté (Shore D) | ASTM D-2240 | 75–80 |

| Résistance à l'abrasion | ASTM D-4060 (CS-17 wheel) | ≤ 12 mg loss (without grit) |

| Water Absorption | ASTM D-570 | 0.04% |

| Résistance chimique | MIL-D-3134 | Excellent (acids, alkalis, oils, solvents) |

| Flame Spread | ASTM E-84 | Classe A |

| Teneur en COV | - | < 4 g/L |

| Cure à temps plein | @ 70°F, 50% RH | 7 jours |

All performance data is based on laboratory testing under controlled conditions. Real-world performance may vary based on substrate, installation, and environmental factors.

Applications idéales

TerraFlex™ EC is engineered for a wide range of demanding settings:

Manufacturing & Industrial Plants

Warehouses & Distribution Centers

Food & Beverage Processing

Hospitals & Laboratories

Schools & Universities

Retail & Supermarkets

Parking Garages & Automotive Shops

Kennels & Veterinary Clinics

Professional Installation & Support

A successful flooring project depends on proper installation. Our certified contractors follow a meticulous process:

Préparation de la surface : Shot blasting to CSP 3-4 profile, cleaning, and moisture testing.

Primer Application: When required, using moisture-tolerant primers.

Body Coat & Broadcast: Applying self-leveling cementitious urethane mortar with decorative chip broadcast.

Grout & Seal: Filling chip voids with epoxy grout to create a smooth, sealed surface.

Topcoat Application: Applying a durable aliphatic urethane topcoat for chemical and UV resistance.

Curing & Protection: Allowing proper cure time before returning to service.

We Provide:

Free site evaluation and moisture testing

Detailed technical specifications and CAD details

On-site training and contractor certification

Lifetime technical support and warranty options

Foire aux questions (FAQ)

Q: How does cementitious urethane differ from epoxy flooring?

A: Cementitious urethane systems offer greater flexibility, thermal shock resistance, and UV stability compared to rigid epoxy systems. They are ideal for environments with temperature variations or exterior exposure.

Q: What is the typical cost per square foot for TerraFlex™ EC?

A: Cost varies based on project size, substrate condition, design complexity, and location. Contact us for a detailed quote tailored to your project.

Q: Can TerraFlex™ EC be applied over existing concrete?

A: Yes, provided the concrete is sound, clean, properly profiled, and within acceptable moisture limits. A professional assessment is recommended.

Q: How long does installation take?

A: Depending on area size and conditions, installation can typically be completed within 2–5 days, with full cure achieved in 7 days at 70°F.

Q: Is a sealer required?

A: The system includes a built-in chemical-resistant topcoat. Additional sealers are not required under normal conditions.

Q: Do you provide pictures or case studies of previous projects?

A: Yes. We maintain a portfolio of completed installations across various industries. Request a gallery from our team.

Trust & Validation

Used by leading companies in food processing, automotive, and logistics sectors.

Compliant with USDA, FDA, and CA Section 01350 indoor air quality standards.

Supported by ASTM and ISO test data for performance verification.

10+ years of manufacturer experience in high-performance resinous flooring.

KAIDA PAINT: Your Trusted Partner in High-Performance Flooring

For over two decades, KAIDA PAINT has been at the forefront of advanced coating technologies, specializing in industrial and commercial flooring solutions. As a certified manufacturer and systems provider, we combine innovative chemistry with real-world expertise to deliver floors that stand up to the toughest environments.

Our TerraFlex™ EC cementitious urethane flooring system exemplifies our commitment to quality, durability, and safety. Unlike standard paints or thin coatings, TerraFlex AB is a complete system engineered for longevity, chemical resistance, and low maintenance. We work directly with contractors, facility managers, and construction companies to ensure every project is specified, installed, and maintained to the highest standards.

Pourquoi choisir KAIDA PAINT ?

Single-Source Responsibility: From product to installation support.

Technical Excellence: ASTM-compliant systems backed by lab data.

Sustainability Focus: Low-VOC, environmentally preferred products.

Des performances éprouvées : Installed in Fortune 500 facilities nationwide.

Your floor shouldn’t be an afterthought—it’s the foundation of your operation. Let our team provide a tailored solution that meets your functional, aesthetic, and budgetary needs.