Description

For contractors, facility managers, and companies seeking a durable, high-performance flooring solution, the ResuShield™ Topfloor HB epoxy flooring system stands out. This high-build coating is engineered to transform rough industrial concrete substrates into a seamless, glossy, and exceptionally resilient surface. It combines mechanical toughness with superior chemical resistance, making it the best choice for environments that face heavy traffic, chemical spills, and stringent hygiene requirements. This product review provides a comprehensive look at its system, application, cost considerations, and why it’s a top solution for warehouse, manufacturing, and commercial use.

Aperçu du produit

The ResuShield™ Topfloor HB is a high-build, multi-coat epoxy flooring system designed for interior concrete floors that require a durable, high-gloss, and easy-to-maintain finish. This system utilizes a robust epoxy resin formulation to create a thick, monolithic sealer that is inherently resistant to staining and attack from common acids, alkalis, fuels, grease, salt, and Skydrol™. It delivers excellent gloss retention, withstands heavy wear and abrasion, and provides a slip-resistant surface. The core value of the ResuShield™ Topfloor HB lies in its ability to protect concrete substrates in the harshest industrial settings while offering an attractive, low-maintenance finish for warehouses, manufacturing plants, and garages.

Common Industrial Flooring Problems & How ResuShield™ Topfloor HB Solves Them

Industrial and commercial floors endure constant abuse. Common pain points for business owners and facility managers include:

Dusting and Degradation: Untreated or poorly coated concrete generates dust, contaminates products, and requires constant cleaning.

Chemical Damage: Spills from oils, grease, acids, and solvents can quickly degrade standard paint or thin coatings, leading to costly repairs.

Mechanical Wear: Forklift traffic, dropped tools, and heavy equipment cause cracks, chips, and rapid surface wear.

Hygiene and Safety Concerns: Porous floors harbor bacteria, are difficult to clean, and can become slippery, especially in food processing or automotive service areas.

Aesthetic Deterioration: Floors quickly look old, stained, and unprofessional, negatively impacting the business environment.

The ResuShield™ Topfloor HB epoxy system is formulated to address these issues directly. Its high-build nature fills minor surface imperfections, creating a non-porous shield. The chemical-resistant topcoat prevents penetration from spills, while its exceptional abrasion resistance ensures a long service life even under heavy loads. The seamless finish eliminates grout lines and cracks where dirt can accumulate, making cleaning quick and effective, and the option for slip-resistant aggregates enhances safety.

Detailed Product Features & Benefits

1. Exceptional Mechanical & Physical Properties

Le système is built to last. Key performance data includes:

Résistance à l'abrasion (ASTM D4060) : Loses only 76 mg after 1,000 cycles with a CS-17 wheel, indicating outstanding durability.

Résistance à l'impact : Passes reverse impact tests greater than 110 inch-pounds (per MIL-D-3134J), protecting the concrete from cracking from heavy blows.

Adhésion : Promotes concrete failure at over 300 psi (per ACI 503R), meaning the coating bonds strongly to the substrate and won’t delaminate.

Résistance à la chaleur : Shows no slip or flow at 158°F (70°C), suitable for environments with warm equipment or processes.

Sans couture et hygiénique : The fluid-applied resin creates a monolithic surface with no joints, preventing dirt and moisture entrapment.

2. Superior Chemical Resistance

This epoxy flooring provides a protective shield against a wide range of substances commonly found in industrial settings, including:

Acids & Alkalis: Resists damage from dilute chemical splashes.

Fuels & Oils: Forms a barrier against gasoline, diesel, and hydraulic fluids.

Grease & Fats: Ideal for automotive shops and commercial kitchens.

Salts & Skydrol™: Performs well in aviation and cold storage applications.

3. Aesthetic Flexibility & Safety

Color & Gloss: Available in standard and custom colors (computer-matched). Provides a high gloss finish (90 @ 60°) that enhances lighting and creates a bright, professional appearance. Also available in gray, white, and other shades.

Résistance au glissement : Can be formulated with grit additives during application to achieve desired slip resistance for safer foot traffic in areas prone to wetness.

Thickness: The system builds a thickness of 25-50 mils, providing a substantial protective layer.

4. Technical Specifications at a Glance

| Propriété | Méthode d'essai | Result / Specification |

|---|---|---|

| Épaisseur du système | - | 25 – 50 mils |

| Résistance à l'abrasion | ASTM D4060 (CS-17 Wheel, 1k cycles) | 76 mg lost |

| Adhesion to Concrete | ACI 503R | >300 psi (concrete failure) |

| Résistance aux chocs | MIL-D-3134J | >110 in-lb (pass) |

| Résistance à la chaleur | MIL-D-3134J | No slip/flow @ 158°F (70°C) |

| Brillant (60°) | Gloss Meter @ 73°F, 50% RH | 90 |

| Inflammabilité | Over Concrete | Self-extinguishing |

| Teneur en COV | EPA Method 24 | < 100 g/L |

Applications idéales

The ResuShield™ Topfloor HB is the specified solution for numerous demanding environments:

Warehouses & Distribution Centers: Withstands forklift and pallet jack traffic.

Manufacturing & Industrial Plants: Resists chemical spills and heavy equipment.

Automotive & Repair Shops: Handles oil, grease, and tire marks.

Transformation des aliments et des boissons : Provides a seamless, easy-to-clean surface for dairy, meat, and beverage plants.

Aircraft Hangars & Maintenance: Resistant to aviation fluids like Skydrol™.

Commercial Garages & Parking Decks: Durable and aesthetically pleasing.

Professional Installation Process & Support

Proper installation is critical to performance. The system must be applied by trained, certified contractors. KAIDA PAINT provides full technical support from specification to project completion.

Principales étapes de l'installation :

Surface Preparation (Prep): Concrete must be abrasive-blasted to a CSP 1-3 profile to remove contaminants and laitance. Moisture testing (ASTM F1869/F2170) is mandatory.

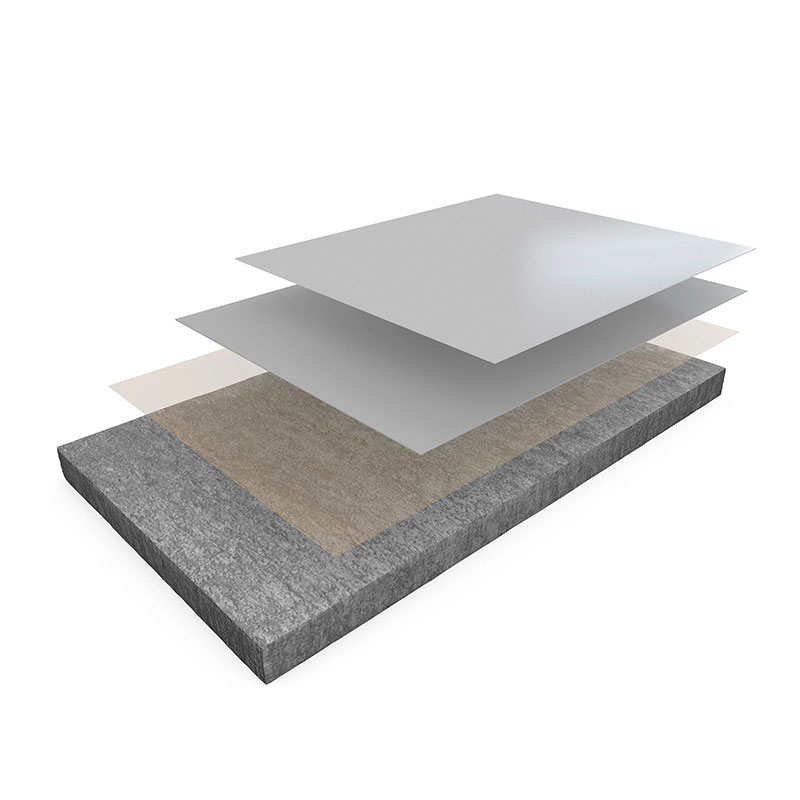

Primer (Basecoat): Apply Resuprime™ 2468 primer to ensure adhesion.

Fill/Base Coat: A mix of Resuprime™ 2468 and Aggregate 5350 is troweled on to build thickness and fill imperfections.

Seal Coat/Topcoat: ResuShield™ 2635 epoxy is applied as the final, chemical-resistant sealer and finish.

Curing: The floor must be protected from traffic and moisture for a minimum of 24-48 hours for full cure.

We assist with installer qualification, on-site technical service, and application guidance to ensure your project is completed to the highest standard.

Foire aux questions (FAQ)

Q: How does the ResuShield™ Topfloor HB compare to a standard epoxy paint or a polyurethane floor?

A : Standard epoxy paint is typically a thin film (3-10 mils) with lower chemical and abrasion resistance. The Topfloor HB is a high-build system (25-50 mils) for heavy-duty use. Polyurethane floors often have better UV resistance and flexibility, but this epoxy system excels in chemical resistance and adhesion on concrete, often at a lower cost for interior applications.

Q: What is the typical cost per square foot for this system?

A : The total cost varies based on prep conditions, floor size, color choice, and geographic location. It is a premium system, so prices are higher than basic coatings but offer far greater long-term value and lower lifetime cost due to durability. Contact us for a specific quote.

Q: Can this be applied as a DIY project?

A : No. This is a professional-grade industrial flooring system. Successful installation requires specialized equipment, proper prep, and precise mixing/application techniques to achieve the advertised performance. We recommend using our network of certified contractors.

Q: How do I clean and maintain this flooring?

A : For daily cleaning, sweep or dust mop. For foot traffic areas, use a neutral floor cleaner. For areas with grease or oils (like automotive shops), use a cleaner/degreaser. Always follow the six-step process: Sweep, Apply cleaner, Agitate, Allow dwell time, Remove solution, and Rinse. Avoid enzyme-based or “no-rinse” cleaners.

Trust & Proven Performance

KAIDA PAINT partners with companies globally to protect their critical assets. Our ResuShield™ Topfloor HB system is specified by leading manufacturers in food processing, logistics, and industrial sectors. We provide comprehensive product data, SDS, and technical guides. Our products are manufactured under strict quality control, and while subject to our standard warranty, their real-world performance in countless facilities is our strongest testimonial.

Choose KAIDA PAINT for Your Flooring Solution

KAIDA PAINT is a leading manufacturer and supplier of high-performance resinous flooring systems. We combine advanced product formulations with deep industrial expertise to deliver solutions that last. Beyond just selling paint, we are your partner in specification, offering free technical consultations, installer referrals, and on-site support to ensure your flooring project is a success from prep to finish.

Ready to transform your concrete floor? Contact our expert team today to discuss your project requirements, receive detailed product information and pictures, and get a professional cost estimate for the ResuShield™ Topfloor HB epoxy flooring system. Let us help you find the best solution for your business.