Description

Aperçu du produit

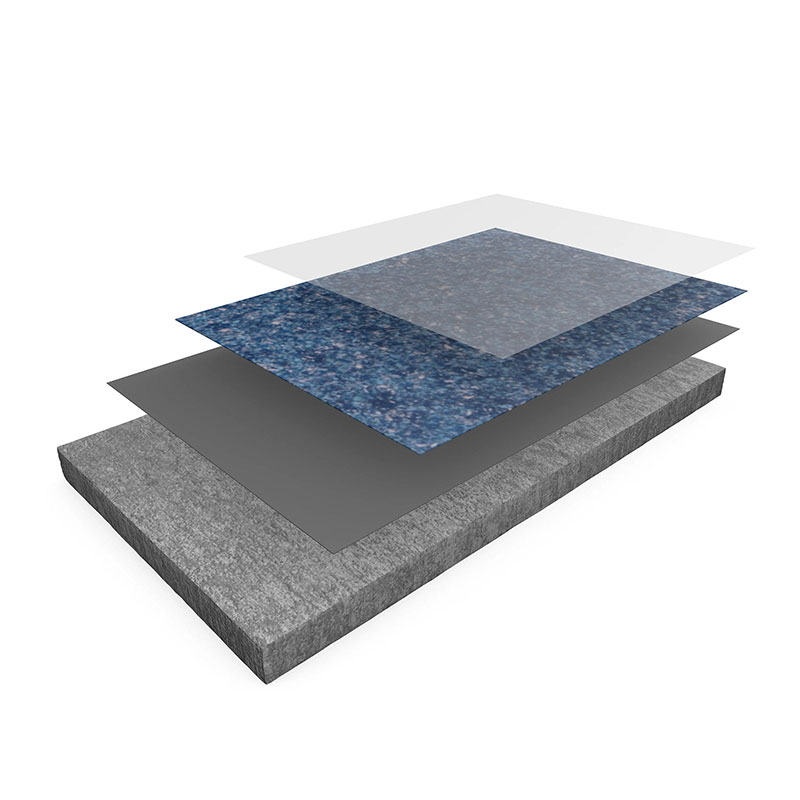

ResuShield™ DSS EV is a high-performance, decorative epoxy flooring system designed for demanding industrial and commercial environments requiring rapid installation and superior chemical resistance. This three-to-four layer system combines a pigmented epoxy basecoat, a decorative stone slurry, and a UV-stable urethane topcoat to create a seamless, durable, and visually appealing floor. Its core innovation lies in providing moderate N-Methyl-2-pyrrolidone (NMP) resistance within seven days and the ability to be applied to green concrete, dramatically reducing facility downtime from the traditional 28-day cure to just 7 days. The system delivers a durable, easy-to-clean, and slip-resistant surface with a natural stone aesthetic, making it the ideal flooring solution for areas where stain and odor resistance, quick installation, and decorative finish are critical.

The Industrial Flooring Challenge: Common Pain Points for Companies & Contractors

Selecting the right flooring system is a critical decision for contractors, facility managers, and companies across various industries. The wrong choice leads to recurring problems, increased cost, and operational disruptions.

Chemical Damage & Staining: Facilities like labs, kitchens, and warehouses face spills from oils, acids, solvents, and cleaning agents that degrade standard paint or coating, causing permanent stains and structural weakening.

Excessive Downtime & High Cost: Traditional industrial flooring installations require lengthy concrete cure times (up to 28 days) and multi-step processes, leading to significant business interruption and higher labor cost.

Poor Durability & Wear: High-traffic areas in warehouses, commercial spaces, and factories suffer from abrasion, impact, and crack formation, resulting in a worn, unprofessional appearance and frequent, costly repair.

Safety Hazards: Slippery surfaces when wet or contaminated pose a major risk in bathrooms, kitchens, and processing areas. Lack of adequate slip resistance can lead to accidents.

Difficult Maintenance & Cleaning: Porous or uneven surfaces trap dirt, grime, and bacteria, making them difficult to clean and maintain to industrial hygiene standards, especially in food service or manufacturer environments.

Aesthetic Limitations: Many functional floors lack design appeal. Companies want a professional finish that enhances their space—options like gray, white, black, or stone looks—without sacrificing performance.

The ResuShield™ DSS EV Solution: Detailed Features & Benefits

Our epoxy flooring system is engineered to address these pain points directly, offering a comprehensive solution for contractors and end-users.

1. Rapid Installation & Reduced Downtime

Fast Cure System: Achieves service readiness faster than traditional systems.

Apply to Green Concrete: Can be installed on 7-day old concrete, bypassing the standard 28-day cure wait. This is a game-changer for companies on tight schedules.

Simplified Layer System: A 3-4 layer system requires fewer steps than traditional 5-7 layer floors, speeding up the installation process for contractors.

2. Superior Chemical & Stain Resistance

7-Day NMP Resistance: Tested to ASTM D1308, offering protection against N-Methyl-2-pyrrolidone, a common chemical challenge.

Broad Chemical Tolerance: Resists a wide range of industrial chemicals, oils, and cleaning solutions, protecting your concrete substrate.

Stain & Odor Resistance: Non-porous, seamless surface prevents absorption of liquids and odors, ideal for restrooms, kitchens, and food service areas.

3. Exceptional Durability & Mechanical Performance

High Abrasion Resistance: Withstands heavy foot and wheeled traffic (ASTM D4060), offering 4-6 times greater abrasion resistance than standard epoxy topcoats.

Forte adhérence : Bonds tenaciously to concrete (ASTM D4541, D7234), ensuring the coating system fails only if the concrete itself fails.

Seamless & Crack-Resistant: The monolithic finish eliminates joints where dirt and moisture accumulate and helps shield against minor substrate crack reflection.

4. Enhanced Safety & Easy Maintenance

Slip-Resistant Surface: Features a dynamic coefficient of friction (DCOF) of 0.72 (ANSI A326.3), exceeding the 0.42 industry standard for slip resistance, even when wet.

Easy to Clean & Maintain: The seamless, non-absorbent finish allows for quick cleaning with standard equipment. Water and spills bead up for easy removal.

Hygienic: Prevents bacterial growth, meeting the clean requirements of commercial, industrial, and institutional settings.

5. Aesthetic Versatility & Professional Finish

Natural Stone Appearance: The decorative slurry creates stunning visual depth and a unique, high-end look reminiscent of marble or terrazzo.

Color & Design Options: Available in a range of standard and custom colors (gray, grey, white, etc.) to match any design or corporate identity.

Satin Finish: The UV-stable urethane topcoat provides a durable, attractive low-gloss or satin gloss finish that reduces light glare and hides minor imperfections.

6. Added Value & Long-Term Performance

LEED® Contribution: Can contribute to Green Building credits under LEED v4, supporting sustainable business practices.

Minor Repairs are Invisible: If damage occurs, repairs can be made that blend seamlessly with the surrounding area.

Long Service Life: The combination of chemical, abrasion, and UV resistance ensures a long-lasting flooring investment.

Technical Specifications & Authoritative Data

The performance of ResuShield™ DSS EV is verified by independent laboratory testing against international standards.

| Propriété | Méthode d'essai | Result / Performance Data |

|---|---|---|

| Résistance à l'abrasion | ASTM D4060 (Taber Abraser, CS-17, 1000g, 1000 cycles) | 5.1 mg loss (HTS Topcoat) |

| Dureté (Shore D) | ASTM D2240 | 80-85 @ 0 sec / 75-80 @ 15 sec |

| Résistance à la traction | ASTM D2370 | 8,000 psi |

| Adhesion to Concrete | ASTM D4541 | >1,250 psi (Concrete failure) |

| Inflammabilité | ASTM D635 | 182 mm/min |

| Chemical Resistance (NMP) | ASTM D1308 Method B | No Effect after 7 days |

| Dynamic Coefficient of Friction (DCOF) | ANSI A326.3-2017 | 0.72 |

| Résistance à la compression | ASTM D695 | 14,000 psi |

| VOC Content (Typical) | ASTM D3960 | Low VOC formulations available |

Ideal Application Areas

This versatile system is the best choice for numerous industrial and commercial environments:

- Industrial & Manufacturing: Warehouses, factory floors, chemical processing plants, automotive bays, electronic cleanrooms.

- Commercial & Institutional: Hospital corridors, school hallways, office buildings, retail spaces, airport concourses.

- Alimentation et boissons : Processing plants, kitchens, bottling facilities, restrooms and locker rooms where stain and odor resistance is key.

- Logistics & Parking: Distribution centers, parking garages, loading docks requiring high abrasion resistance.

- Specialty Areas: Basement renovations, laboratory floors, showrooms requiring a high-gloss or decorative finish.

Professional Installation & Technical Support

A successful flooring project depends on proper preparation and application. We partner with certified contractors and provide comprehensive support.

Principales étapes de l'installation :

Surface Preparation & Prep: Concrete must be clean, dry, and sound. Steel shot blasting to a CSP 3-5 profile (ICRI 310.2R) is required for proper adhesion.

Test d'humidité : Critical step to measure internal humidity (ASTM F2170). Our optional moisture vapor barrier (Resuprime MVB) addresses high-moisture substrates.

Primer/Basecoat Application: Apply pigmented Resuflor DSP epoxy as a primer and basecoat.

Decorative Slurry Application: Trowel-apply the Resuflor DSS slurry mixture to achieve the desired thickness (60-80 mils) and stone effect.

Topcoat Application: Apply the final sealer – Resutile HTS 100 urethane topcoat – for chemical resistance, slip resistance, and UV stability.

Curing & Traffic: Allow system to cure as per guidelines before allowing foot traffic or heavy use.

Our Support to Contractors & Companies:

Free Technical Specifications: Download ready-to-use specs for your projects.

On-Site Assessment: Our experts can help evaluate your substrate and conditions.

Application Guidance: Detailed installation manuals and direct access to technical service.

Quality Assurance: Partnering with trained, experienced installer networks.

Foire aux questions (FAQ)

Q: How long does the ResuShield DSS EV flooring system take to install?

A : The system is designed for a fast turnaround. While total project time depends on area square footage and conditions, the key advantage is its ability to be applyied to 7-day old ‘green’ concrete and its rapid cure times. This can reduce overall facility downtime by weeks.

Q: Can I install this flooring system myself (DIY)?

A : We strongly recommend professional installation by approved contractors. Achieving the system’s performance and aesthetic requires precise preparation and application techniques. Incorrect installation can void warranties.

Q: How does the cost compare to tile or standard epoxy?

A : While the initial price may be higher than basic epoxy paint, its long-term cost is often lower due to longevity, reduced maintenance, and minimal downtime. It provides more value than tile (no grout) and outperforms standard epoxy.

Q: How do I clean and maintain my ResuShield floor?

A : Cleaning is simple. Sweep or dust mop daily. For periodic cleaning, use a neutral pH cleaner. The seamless surface and stain resistance make upkeep easy.

Q: What is the minimum temperature for installation?

A : Substrate and ambient temperatures should be between 50°F and 90°F during application. Materials must be kept from freezing.

Trust & Proven Performance

ResuShield™ DSS EV is backed by the global expertise and manufacturer quality assurance of a world leader in performance coatings. Our products are specified by leading companies and applied by professional contractors on thousands of projects worldwide, from residential basement upgrades to multinational industrial warehouse complexes. We provide not just a product, but a complete flooring solution supported by technical data, application guides, and expert advice.

Ready for a Durable, Beautiful Floor? Contact Kaida Paint Today!

About Kaida Paint: Kaida Paint is a leading manufacturer and supplier of high-performance industrial and commercial coatings. We combine innovative product formulations with in-depth service and support, partnering with contractors and companies to deliver flooring solutions that stand up to real-world challenges. Our team provides everything from product selection and technical specs to on-site application guidance.

Why Choose Kaida for Your ResuShield DSS EV Project?

Direct Manufacturer Support: Get accurate information and technical backup directly from the source.

National Supply Chain: Reliable supply and logistics, whether your project is in a major city or remote country location.

Contractor Network: We can connect you with experienced, approved installers in your area (near you).

Custom Solutions: Need a specific color (gray, white, custom)? We can help.

Get Your Free Quote or Technical Consultation

Stop compromising between performance, cost, and aesthetics. Let’s discuss how the ResuShield™ DSS EV epoxy flooring system can solve your industrial flooring challenges.

Contact us now for a competitive price, detailed product pictures, system specifications, and to find a qualified contractor near you.

À propos de KAIDA PAINT

Kaida Paint: Your Trusted Partner for High-Performance Flooring Solutions

For over 15 years, Kaida Paint has been at the forefront of developing and supplying advanced coating solutions for the most demanding environments. We understand that your floor is a critical business asset—it needs to protect your substrate, ensure safety, facilitate operations, and project a professional image. That’s why we engineer products like the ResuShield™ DSS EV, blending raw material science with practical application needs.

Our advantage lies in our dual role as both a manufacturer and a solution provider. We don’t just sell paint; we offer:

In-House R&D: Continuous innovation to meet evolving industrial challenges.

Rigorous Quality Control: Every batch meets stringent standards, ensuring consistent performance you can rely on.

Direct Technical Expertise: Our specialists can help you select the right system, troubleshoot substrate issues (crack, moisture), and optimize application.

Global Reach, Local Service: Whether you’re a contractor sourcing materials for a local residential project or a multinational company specifying for a factory in China, we have the supply chain and support network.

Let’s Build a Stronger Foundation Together.

Choosing a floor is a significant decision. Partner with a team that brings expertise, quality products, and dedicated support to the table. Contact Kaida Paint today to discuss your project requirements, request product samples or pictures, and receive a detailed quote. Discover why leading businesses and contractors trust us for their flooring solutions.