Description

Aperçu du produit

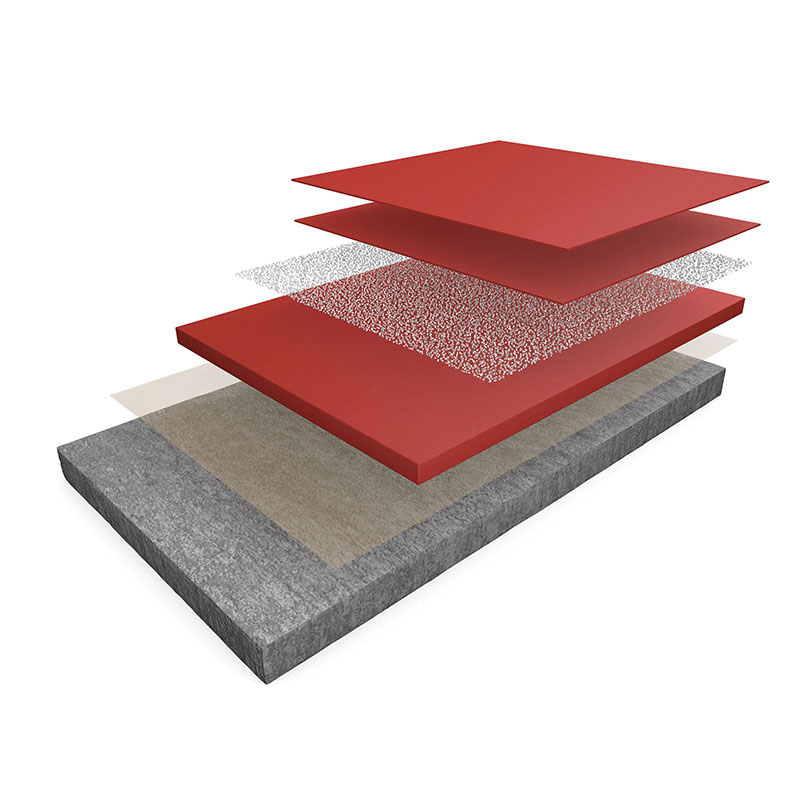

CrylForte™ SL is a self-leveling, seamless acrylic flooring system engineered for demanding industrial, commercial, and institutional environments. Utilizing a 100% reactive methyl methacrylate (MMA) resin formula, it creates a high-strength, monolithic overlay with an integral quartz aggregate broadcast and durable pigmented topcoats. This system delivers exceptional resistance to chemicals, impact, and abrasion while providing a seamless, easy-to-clean surface. CrylForte™ SL is the definitive solution for facilities requiring a fast-curing, high-performance floor that combines long-term durability with minimal downtime.

Common Industrial Flooring Problems & Scenarios

Industrial floors face relentless challenges that compromise safety, hygiene, and operational efficiency. Traditional solutions like epoxy, vinyl tile, or plain concrete often fall short.

Key Pain Points:

- Deterioration & Damage: Cracks, spalling, and dusting from heavy traffic and impact.

- Attaque chimique : Stains, erosion, and degradation from oils, solvents, acids, and cleaning agents.

- Hygiene & Cleanliness: Porous surfaces harbor bacteria, are difficult to clean, and fail to meet standards for food processing or pharmaceutical spaces.

- Downtime: Lengthy installation and cure times disrupt business operations.

- Slippery Surfaces: Insufficient slip resistance creates safety hazards, especially in wet areas.

Application Scenarios:

- Food & Beverage Plants: Needs seamless, non-porous floors that can withstand harsh sanitizers, acids, and hot water pressure washing.

- Warehouses & Logistics Centers: Requires extreme abrasion resistance to withstand constant forklift traffic and heavy loads without showing wear.

- Garages de stationnement : Demands a coating resistant to de-icing salts, automotive fluids, UV exposure, and tire abrasion.

- Installations de fabrication : Must endure chemical spills, thermal shock, and mechanical impact from dropped tools and equipment.

CrylForte™ SL Solution & Key Features

The CrylForte™ SL acrylic flooring system directly addresses these challenges with its superior formulation and design.

Unmatched Performance Characteristics:

- Rapid Cure & Minimal Downtime: Achieves a tack-free cure in 45-60 minutes at 68°F (20°C), allowing for quick return to service—often within hours.

- Résistance chimique supérieure : The non-porous, 100% reactive resin matrix provides outstanding resistance to a wide range of chemicals, including oils, greases, acids, and alkalis, making it easy to clean and maintain.

- Durabilité exceptionnelle : High tensile and compressive strength (up to 8,000 psi) combined with a broadcast quartz aggregate (Flintshot) delivers outstanding abrasion and impact resistance.

- Sans couture et hygiénique : The fluid-applied, self-leveling system creates a monolithic surface with no grout lines or seams to trap dirt, moisture, or bacteria, simplifying cleaning and meeting stringent hygiene standards.

- Application polyvalente : Can be installed over concrete at a wide temperature range (35°F – 90°F) and accommodates moisture mitigation strategies. Suitable for basement, warehouse, and factory settings.

- Safety & Comfort: Available in various slip-resistant textures. The system can also be formulated with low-VOC components (<100 g/L) to support better indoor air quality.

- Aesthetic Flexibility: Available in a wide range of standard and custom colors and gloss levels, from satin to high-gloss, to enhance the design and brightness of any commercial or industrial space.

Spécifications et données techniques

| Paramètres | Méthode d'essai | Primer (P-101) | Self-Leveling Body Coat (G-201) | Topcoat (T-301) |

|---|---|---|---|---|

| Reactive Resin Content | – | 100% | 100% | 100% |

| Teneur en COV | – | <100 g/L | <100 g/L | <100 g/L |

| Résistance à la traction | ASTM D638 | 3,550 psi | 2,000 psi | 3,550 psi |

| Résistance à la compression | ASTM C109 | – | 8,000 psi | – |

| Résistance à la flexion | ASTM D790 | – | 3 700 psi | – |

| Absorption de l'eau | ASTM D570 | 0.04% | 0.04% | 0.4% |

| Electrical Resistivity (Volume) | ASTM D257 | 10^15 ohm-cm | 10^15 ohm-cm | 10^15 ohm-cm |

| Pot Life @ 68°F | – | 10-20 min | 10-20 min | 10-15 min |

| Cure Time (tack-free) @ 68°F | – | 45-60 min | 45-60 min | 45-60 min |

| Nominal System Thickness | – | – | 3/16 inch (with Flintshot) | – |

The system complies with relevant industry standards for hygiene and air quality, including USDA/FDA guidelines for incidental food contact and California Section 01350 for indoor air quality.

Principaux domaines d'application

The CrylForte™ SL acrylic flooring system is the best choice for environments that demand resilience, cleanliness, and speed.

- Transformation des aliments et des boissons : Resists stains from oils, sugars, and acids; withstands daily caustic cleaning.

- Pharmaceutical & Biotechnology: Provides a seamless, cleanable, and chemical-resistant surface for controlled environments.

- Automobile et aérospatiale : Handles fluid spills, tire traffic, and heavy equipment with ease.

- Logistics & Distribution Centers: Endures extreme abrasion from high-volume forklift and pallet jack traffic.

- Parking Structures & Garages: Offers UV stability, resistance to salts and automotive fluids, and durable finish.

- Commercial Kitchens & Restaurants: Delivers a slip-resistant, grease-proof, and easy-to-mop surface.

- Educational & Healthcare Facilities: Creates a safe, durable, and low-maintenance floor for high-traffic areas.

Installation Process & Technical Support

A successful installation hinges on proper preparation and expert application.

Principales étapes de l'installation :

- Préparation de la surface : Concrete substrate must be shot-blasted to a CSP 3-4 profile, clean, dry, and free of contaminants. Critical moisture and bond tests are performed.

- Priming: Application of the MMA primer (CrylForte P-101) to ensure optimal adhesion to the concrete base.

- Body Coat & Broadcast: The self-leveling MMA resin (CrylForte G-201) is poured, raked to level, and immediately broadcast with Flintshot quartz aggregate.

- Topcoating: Two pigmented MMA topcoat (CrylForte T-301) layers are roller-applied for color, gloss, and enhanced chemical protection.

Our Support: We provide comprehensive technical data sheets, on-site specification assistance, and access to a network of trained, experienced contractors to ensure your acrylic flooring system is installed to the highest standard.

Foire aux questions (FAQ)

Q: How does CrylForte™ SL compare to an epoxy flooring system?

A: While both are resinous floors, CrylForte™ SL’s MMA resin cures much faster (minutes/hours vs. days for epoxy), can be applied in colder and damper conditions, and typically offers higher resistance to thermal shock and UV yellowing. Epoxy may have higher initial adhesion but can become brittle over time.

Q: What is the typical lifespan of a CrylForte™ SL floor?

A: With proper installation and maintenance, a CrylForte™ SL floor can last 15+ years in heavy industrial settings. Its longevity surpasses many epoxy and polyurethane systems.

Q: Can it be installed over existing tile or sealed concrete?

A: All existing coatings, sealers, adhesives (from vinyl tile), and latex paint must be completely removed via mechanical preparation (grinding, shot blasting) to ensure a sound, clean concrete substrate for proper bonding. It cannot be applied as a coat over uncertain surfaces.

Q: How do I maintain and clean the floor?

A: Regular sweeping and damp mopping with neutral pH cleaners are sufficient. Avoid harsh acidic or solvent-based cleaners. The seamless surface means there is no grout to stain or clean. Periodic repolishing is generally not needed; reapplication of a sealant or wax is not required.

Trust & Proven Performance

CrylForte™ SL is specified by leading manufacturers and companies across the globe for critical infrastructure. Our products are backed by rigorous testing and a network of approved installers. We provide material warranties and support to ensure customer satisfaction, from the initial design to the final finish.

KAIDA PAINT Brand

For over 15 years, Kaida Paint has been at the forefront of advanced coating technology, dedicated to developing and supplying high-performance solutions for the most demanding industrial and commercial environments. As a specialist manufacturer of resinous flooring systems, we understand that a floor is more than a surface—it’s a critical asset that impacts safety, productivity, and operational costs.

Our flagship product, the CrylForte™ SL acrylic flooring system, embodies our commitment to innovation. We formulate our products with high-quality resins and polymers to deliver unmatched protection against abrasion, impact, and chemical attack. But our service goes beyond the can. We partner with a network of certified contractors and provide unparalleled technical support to ensure every installation is a success, from the design phase to the final finish.

Whether you’re managing a warehouse needing extreme durability, a food factory requiring supreme cleanability, or a garage seeking a stain-resistant finish, Kaida Paint has the expertise and the products to meet your challenge. Contact our team today for a free project consultation. Let’s build a better foundation for your business together.

Call to Action: Partner with Kaida Paint

At Kaida Paint, we are more than just a manufacturer of high-performance coatings; we are your solutions partner. Specializing in advanced industrial flooring systems like CrylForte™ SL, we combine top-tier products with deep technical expertise. Our team supports contractors and facility managers through every step—from system selection and specification to installation guidance and quality assurance.

Why Choose Kaida Paint?

- Expert Formulations: We develop and supply proven, high-performance acrylic, epoxy, and polyurethane flooring resins.

- Technical Leadership: Get expert advice to solve complex basement moisture, chemical resistance, or heavy traffic challenges.

- Reliable Support: We stand behind our products and your project’s success.

Ready to upgrade your facility with a floor that stands up to your demands? Contact Kaida Paint today for a detailed quote, technical consultation, or to find a qualified installer near you. Let us help you get the best finish for your business.