Description

Aperçu du produit

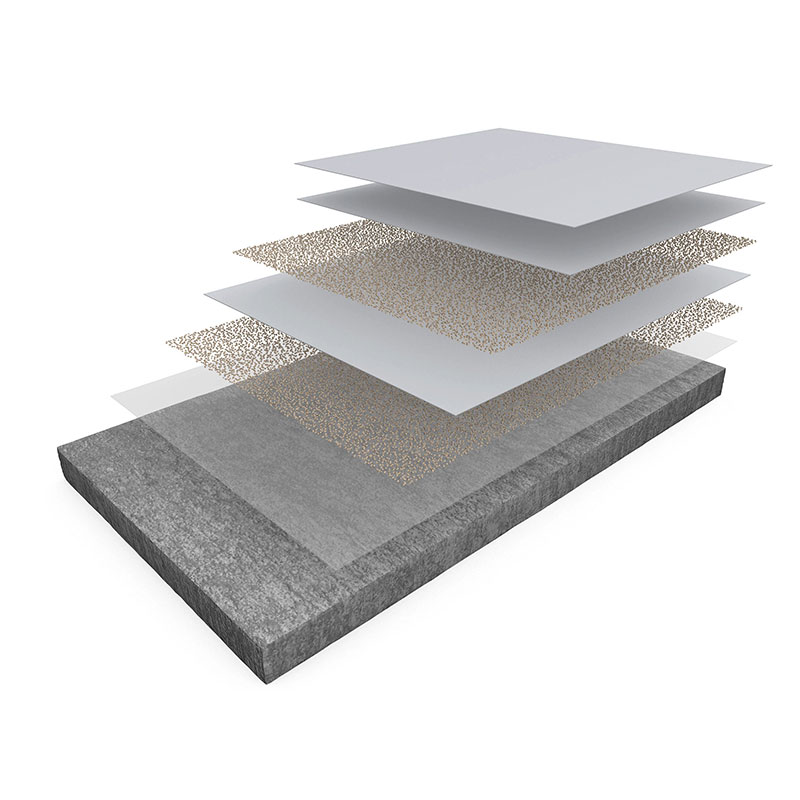

ResuShield™ Shop Floor DB is a heavy-duty, multi-layer epoxy flooring system specifically engineered for high-traffic industrial and commercial environments. This robust system combines a double broadcast of silica sand with high-solids epoxy resins and a durable, UV-stable urethane topcoat. It delivers exceptional resistance to abrasion, impact, chemicals, and heavy loads. The ResuShield™ Shop Floor DB system provides a seamless, easy-to-clean, and highly durable finish, making it the ideal solution for manufacturing plants, warehouses, vehicle maintenance facilities, and other demanding spaces.

User Pain Points & Scenario Analysis

Industrial and commercial floors face relentless abuse, leading to costly downtime, safety hazards, and premature replacement. Common problems include:

Dusting and Degradation: Untreated or poorly coated concrete creates dust, contaminates products, and deteriorates quickly.

Cracks and Damage: Heavy machinery, impact from dropped tools, and constant traffic cause cracks, spalling, and surface damage.

Attaque chimique : Spills from oils, greases, solvents, and cleaning chemicals can penetrate and break down standard floors.

Safety Risks: Slippery surfaces when wet or soiled increase the risk of slips and falls.

Difficult Cleaning: Porous or textured surfaces trap dirt, grime, and bacteria, making sanitation a challenge, especially in food processing or pharmaceutical areas.

Specific scenarios where ResuShield™ Shop Floor DB provides the answer:

Automotive Shops: Resists tire marks, oil, grease, and antifreeze while standing up to heavy tool drops and vehicle traffic.

Warehouses & Logistics Centers: Withstands constant forklift traffic, heavy pallet impacts, and provides a dust-free surface for inventory.

Services de restauration : Offers a non-porous, seamless surface that is easy to sanitize and resists stains from acids, sugars, and cleaning agents.

Manufacturing Plants: Protects against chemical spills, metal shavings, and extreme mechanical wear.

Solution & Key Features

The ResuShield™ Shop Floor DB system is designed to directly address these industrial challenges through its superior construction and performance.

Core System Construction:

1st Basecoat & Broadcast: A layer of high-solids epoxy (ResuShield MPE) is applied, followed by an immediate broadcast of 20-40 mesh silica sand for initial texture and build.

2nd Basecoat & Broadcast: A second, thicker coat of epoxy is applied and broadcast with more silica sand, creating an extremely rugged, aggregate-reinforced layer.

Grout Coat: Another coat of epoxy fills the voids between the sand particles, locking the aggregate in place and creating a solid, monolithic slab.

Couche de finition : A final coat of aliphatic, moisture-cure urethane (Resutile HTS 100) provides a UV-stable, chemical-resistant, and satin-finish surface that is easy to clean.

Key Performance Features:

Durabilité inégalée : Features a double broadcast of silica sand for exceptional wear and impact resistance. The system’s abrasion resistance is proven with low Taber Abraser loss values.

Résistance chimique supérieure : The epoxy and urethane layers provide excellent protection against a wide range of oils, greases, solvents, and mild acids, safeguarding your béton substrate.

Sécurité renforcée : The textured surface from the silica sand broadcast provides a customizable slip-resistant finish, even when wet. Wet static coefficient of friction (SCOF) meets high safety standards.

Sans couture et hygiénique : The fluid-applied system creates a seamless, non-porous flooring surface that prevents dirt and moisture penetration, making cleaning quick and effective.

Long-Lasting Aesthetics: The UV-stable urethane topcoat resists yellowing and maintains its color and satin finish for years, keeping your facility looking professional.

Technical Data & Specifications

The performance of the ResuShield™ Shop Floor DB system is backed by rigorous testing against international standards.

| Propriété | Méthode d'essai | Result/Value |

|---|---|---|

| Résistance à l'abrasion | ASTM D4060 (Taber Abraser) | 18 mg loss (Topcoat System) |

| Adhesion to Concrete | ASTM D7234 | 732 psi (Concrete failure) |

| Résistance à la compression | ASTM D695 | 13,500 psi |

| Résistance à la traction | ASTM D2370 | 8,000 psi |

| Shore D Hardness | ASTM D2240 | 80-85 @ 0 sec |

| Wet Static COF | ANSI/NFSI B101.1 | 0.94 |

| Teneur en COV | ASTM D3960 | <50 g/L (Low VOC) |

| Absorption de l'eau | ASTM D570 | 0.2% weight increase |

Domaines d'application

The versatility of the ResuShield™ Shop Floor DB makes it the best choice for numerous industrial and commercial settings:

Manufacturing & Assembly Plants

Automotive & Aircraft Hangars

Warehouses & Distribution Centers

Food & Beverage Processing Facilities

Chemical Processing Areas

Parking Garages & Service Bays

Fire Stations & Municipal Buildings

Commercial Kitchens & Laundries

Installation Process & Support

A successful installation is critical for performance. The system must be installed by qualified contractors.

Surface Preparation (Prep): Concrete must be shot-blasted to a CSP 4-6 profile (per ICRI 310.2R) to ensure proper adhesion. All contaminants must be removed.

Primer (if needed): On porous concrete, a primer may be used to minimize outgassing.

Basecoat & Broadcast Application: The epoxy basecoat is mixed and applied, followed by the immediate broadcast of sand.

Curing & Cleaning: The system cures between layers. Loose sand is vacuumed before the next coat.

Grout & Topcoat Application: The epoxy grout coat is applied, followed by the final urethane topcoat.

Curing: The floor requires sufficient dry time before opening to traffic (24 hours for light traffic, 7 days for full properties).

We provide comprehensive technical support, from specification guidance to on-site consultation, ensuring your contractor achieves a flawless finish.

Foire aux questions (FAQ)

Q: How does ResuShield™ Shop Floor DB compare to standard epoxy floor paint?

A : It is far more durable. Standard epoxy paint is a thin coating. Our system is a 1/8″ thick, aggregate-reinforced flooring system designed for heavy industrial abuse, offering superior resistance to impact, wear, and chemicals.

Q: What is the typical cost per square foot installed?

A : The price varies based on floor condition, size, and location. For an accurate quote, contact us with your project’s square footage and details. It is an investment that saves money on long-term repair and replacement.

Q: How long does the installation take?

A : For a typical project, allow 3-5 days including preparation, application, and curing. Larger areas may require more time. Traffic can usually resume in 24-48 hours.

Q: Can it be installed in a basement or over existing tile?

A : It is designed for above-grade concrete. Basement slabs require thorough moisture testing (ASTM F2170). It can be installed over properly prepared existing flooring, but the substrate must be sound, clean, and profiled.

Q: How do I clean and maintain it?

A : Daily dry mopping or sweeping is recommended. Periodic cleaning with a mild detergent and water is sufficient. Avoid harsh chemicals. Specific maintenance guides are provided upon installation.

KAIDA PAINT Brand & Product Introduction

For years, Kaida Paint has been at the forefront of developing advanced coating solutions for the most demanding industrial and commercial environments. We understand that your floor is a critical business asset. Our ResuShield™ product line, including the flagship Shop Floor DB system, is the result of extensive R&D focused on durability, safety, and longevity. Unlike generic suppliers, we combine manufacturing excellence with deep technical expertise. We don’t just sell paint; we deliver proven flooring systems backed by science and supported by a team dedicated to your project’s success. Whether you’re a facility manager overseeing a warehouse retrofit or a contractor seeking reliable materials, partnering with Kaida Paint means investing in quality, performance, and peace of mind. Contact us to discuss your specific flooring challenge.

Why Choose Our Solution?

Our company is more than just a manufacturer; we are your service and solutions partner. We have supplied high-performance flooring systems to businesses across the country. Our technical team ensures you get the right product for your needs, and we work with a network of certified, professional installers.

Partner with Kaida Paint

At Kaida Paint, we specialize in formulating and supplying high-performance industrial coatings like the ResuShield™ line. As both a manufacturer and a technical partner to contractors, we understand what it takes to deliver a successful, long-lasting floor.

Our advantages for your project:

Expert Formulation: We develop products like ResuShield™ Shop Floor DB for real-world industrial challenges.

Technical Support: From system specification to on-site troubleshooting for your contractor.

Quality Assurance: Consistent, high-quality materials delivered to your job site.

Proven Results: Trusted by companies in warehouse, manufacturing, and commercial sectors.

Ready to upgrade your floor? Contact Kaida Paint today for a technical data sheet, a free project consultation, or to be connected with a qualified installer in your city. Let us help you find the most cost-effective and durable solution for your facility.

Discover the Kaida Paint difference. Request your quote now.