Description

Aperçu du produit

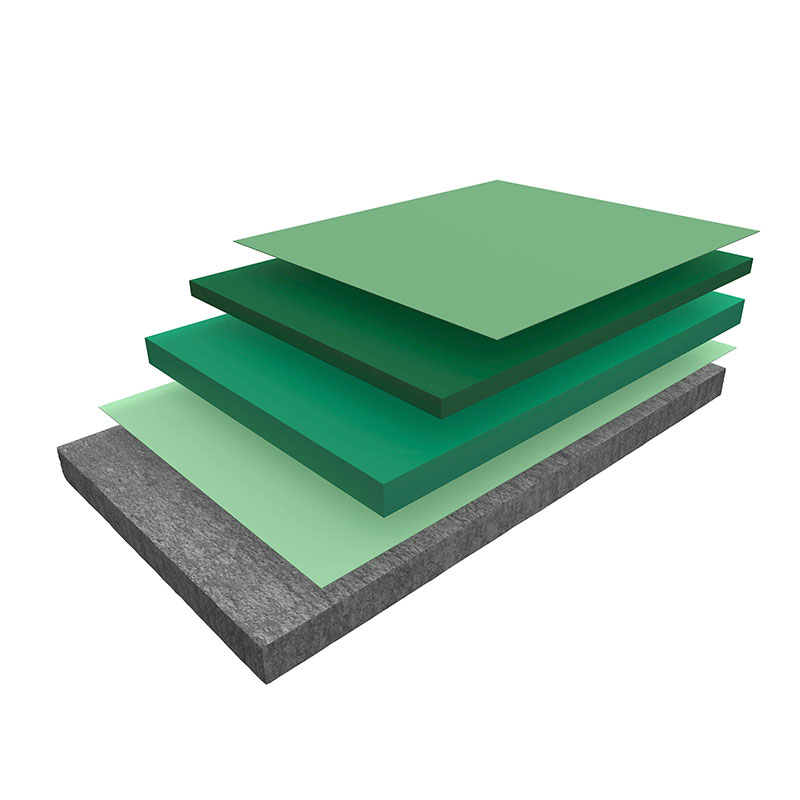

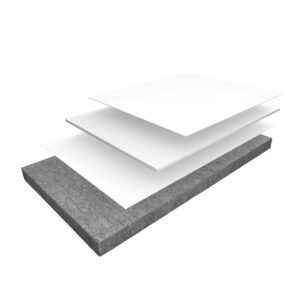

FlexTop™ Comfort SL is a high-performance, 1/4-inch thick elastomeric urethane flooring system engineered for demanding industrial and commercial environments. By integrating advanced polyurethane resin technology within a flexible, multi-layer construction, it forms a seamless, monolithic surface that bridges cracks and resists wear. It delivers exceptional abrasion resistance, impact absorption, and chemical tolerance, alongside ergonomic underfoot comfort and sound dampening. This coating provides a durable, easy-to-clean, and aesthetically versatile solution for warehouses, manufacturing plants, laboratories, and public facilities.

User Pain Points & Scenario Analysis

Industrial and commercial floors face relentless challenges that compromise safety, hygiene, and longevity. Common issues include:

Cracking & Spalling: Unforgiving concrete substrates crack, leading to dust, trip hazards, and water infiltration.

Dusting & Degradation: Constant traffic and abrasion wear down surfaces, creating dust that contaminates processes and products.

Attaque chimique : Spills from oils, greases, solvents, and cleaning agents can degrade standard flooring.

Heavy Impact Damage: Dropped tools, rolling equipment, and heavy loads cause chips, cracks, and surface deformation.

Hygiene & Cleanliness Concerns: Porous surfaces and grout lines in traditional floors harbor bacteria and are difficult to sanitize.

Slippery Surfaces: Wet or oily conditions create slip-and-fall risks for personnel.

Specific scenarios illustrate these needs:

Food & Beverage Plants: Require floors that withstand frequent hot water/chemical washdowns, resist acids/alkalis, and provide a seamless, sanitary surface for compliance.

Logistics Warehouses: Need a coating that can endure constant forklift traffic, heavy point loads from racking, and abrasive wheel wear without breaking down.

Automotive Workshops: Demand urethane floors resistant to hydraulic fluids, fuels, and tire marks, with easy clean-up and a professional finish.

Pharmaceutical Facilities: Require non-porous, non-shedding surfaces that support cleanroom protocols and resist a broad range of disinfectants.

Solution & Key Features of FlexTop™ Comfort SL

FlexTop™ Comfort SL directly addresses these challenges with a superior polyurethane flooring solution. Here are its core selling points:

Mechanical & Structural Performance

Superior Abrasion Resistance: Exceptionally low wear loss (comparable to 119 mg per ASTM D4060), ensuring long life under heavy cart and forklift traffic.

High Impact & Indentation Resistance: Withstands impacts greater than 320 in-lbs (ASTM D2794), preventing damage from dropped objects.

Flexible & Crack-Bridging: Its elastomeric nature (167% elongation per ASTM D2370) allows it to span and flex with minor substrate movement, preventing reflective cracking.

Durable Tensile Strength: Robust tensile strength (534 psi per ASTM D2370) contributes to overall system integrity.

Chemical & Environmental Resistance

Resists a wide range of chemicals, including oils, greases, dilute acids, alkalis, and many solvents once fully cured (7-day cure for full resistance).

Sans soudure et sanitaire : No grout lines or seams eliminate harborage points for bacteria, mold, and dirt, simplifying cleaning and meeting high hygiene standards.

Low VOC & Sustainable Options: Formulated with low VOC content and can incorporate bio-based materials, contributing to better indoor air quality and environmental goals.

Functional & Safety Benefits

Enhanced Ergonomics: The 1/4-inch thick cushion layer reduces foot fatigue and dampens ambient noise, improving occupant comfort and well-being.

Slip-Resistant Surface: Can be finished with appropriate textures or aggregates to achieve the desired anti-slip rating (e.g., R9-R11) for safety in wet areas.

Excellent Adhesion: Bonds tenaciously to properly prepared concrete, ensuring long-term performance without delamination.

Aesthetic & Customization

Seamless, Glossy Finish: Provides a bright, attractive, and professional appearance that enhances facility lighting.

Custom Color Options: Available in a wide range of standard and custom colors to meet corporate branding or functional zoning needs.

Spécifications et données techniques

| Propriété | Méthode d'essai | Value/Result | Notes |

|---|---|---|---|

| Épaisseur du système | – | 250 mils (1/4″) | Total build |

| Résistance à l'abrasion | ASTM D4060 | 119 mg loss | (Taber CS-17, H-18 wheel) |

| Dureté | ASTM D2240 | Shore A: 44 | Measured on SofTop layer |

| Dureté | ASTM D2240 | Shore D: 12 | Measured on SofTop layer |

| Elongation | ASTM D2370 | 167% | Demonstrates flexibility |

| Résistance à la traction | ASTM D2370 | 534 psi | |

| Résistance aux chocs | ASTM D2794 | >320 in-lbs | |

| Recoat Window | ASTM D6677 | Within 24 hrs | For all system layers |

| Full Cure for Chemical Resistance | – | 7 Days | Consult for specific chemicals |

Domaines d'application

FlexTop™ Comfort SL is the ideal industrial and commercial flooring choice for sectors where performance, safety, and durability are paramount:

Pharmaceutical & Life Sciences: Cleanrooms, labs, hallways.

Transformation des aliments et des boissons : Production areas, packaging, wash-down zones.

Electronics & Semiconductor: ESD-controlled environments, manufacturing.

Automotive: Assembly plants, repair garages, showrooms.

Logistics & Warehousing: Distribution centers, loading docks, high-traffic aisles.

Soins de santé Hospital corridors, clinics, labs.

Education & Public Spaces: Schools, universities, stadiums, airports.

Installation Process & Technical Support

Professional installation by certified contractors is crucial for optimal performance. The key steps are:

Préparation de la surface : Concrete substrate must be sound, clean, and abrasive-blasted to a CSP 2-3 profile. All contaminants, laitance, and weak mortar must be removed.

Primer & Broadcast: Application of a high-adhesion primer (e.g., FasTop P/T) followed by a silica sand broadcast for mechanical key.

Membrane & Intermediate Coat: Installation of the flexible polyurethane membrane (SofTop SD) and intermediate coat (SofTop Comfort SLR Flex) to build thickness and cushioning.

Topcoat Application: Final application of a high-performance urethane topcoat (e.g., Resutile HTS 100) for superior abrasion, chemical resistance, and aesthetic finish.

Curing: The system requires a 7-day cure before exposure to wet cleaning or full chemical service.

Our Technical Support includes: On-site evaluation, detailed specification writing, contractor training, and application oversight to ensure the system is installed correctly.

Foire aux questions (FAQ)

Q: What is the difference between a polyurethane floor and an epoxy floor?

A : While both are resin-based, polyurethane flooring offers superior flexibility, UV stability (resists yellowing), better abrasion resistance, and higher thermal shock resistance. Epoxy floors are typically harder and more rigid but can become brittle and crack with substrate movement. Urethane is often chosen for demanding, high-traffic, or outdoor-exposed areas.

Q: How long does it take to install FlexTop™ Comfort SL?

A : Installation time depends on area size and conditions. Typically, the multi-coat system can be installed over 2-4 days, with light traffic possible in 24-48 hours after the final topcoat. Full cure is achieved in 7 days.

Q: How do I maintain a polyurethane floor coating?

A : Maintenance is simple. Regular sweeping or dust mopping, followed by periodic damp mopping with a mild detergent, is usually sufficient. Avoid harsh abrasive cleaners. The seamless nature prevents dirt entrapment, making it one of the easiest industrial flooring types to keep clean.

Q: What is the minimum application temperature?

A : The substrate and ambient temperature should be between 40°F and 90°F (5°C to 32°C) during installation. Special procedures are required for applications outside the ideal range.

Q: What is the typical cost of a polyurethane floor coating?

A : The cost of a FlexTop™ Comfort SL system varies based on project size, condition of the existing concrete, and geographical location. It is a premium product offering long-term value through reduced maintenance and extended service life. Contact us for a detailed quote.

Social Proof & Trust Building

Case Studies: Our urethane flooring solutions have been successfully installed in Fortune 500 manufacturing plants, national food distribution centers, and major university research facilities.

Certifications & Standards: Our products and systems are formulated and tested to meet or exceed relevant international standards for performance and safety.

Expert Network: We work exclusively with a network of highly trained and certified installers to guarantee quality results.

KAIDA PAINT Brand :

As a leading innovator in high-performance industrial coatings, KAIDA PAINT specializes in developing and manufacturing advanced resin-based flooring systems. We partner with professional contractors and facility managers to provide not just premium products, but complete technical solutions—from specification support to on-site application guidance.

Choosing the right floor is a critical investment in your facility’s safety, efficiency, and longevity. At KAIDA PAINT, we don’t just sell coatings; we deliver engineered solutions. As a specialized manufacturer of high-performance urethane and epoxy resin systems, we understand the unique stresses faced by industrial and commercial floors.

Our FlexTop™ Comfort SL system embodies our commitment to innovation, combining advanced material science with practical design to solve real-world problems. We support this commitment by providing:

Unmatched Product Quality: Rigorously tested formulations ensure consistent performance.

Deep Application Knowledge: Our technical team works directly with contractors and installers to ensure flawless execution.

End-to-End Partnership: From initial substrate assessment to final finish, we are your dedicated resource.

Partner with KAIDA PAINT for a floor that performs as hard as your business does. Let’s discuss your project requirements, cost considerations, and performance goals. Request a consultation or a detailed quote today and take the first step toward a superior flooring solution.