Description

Aperçu du produit

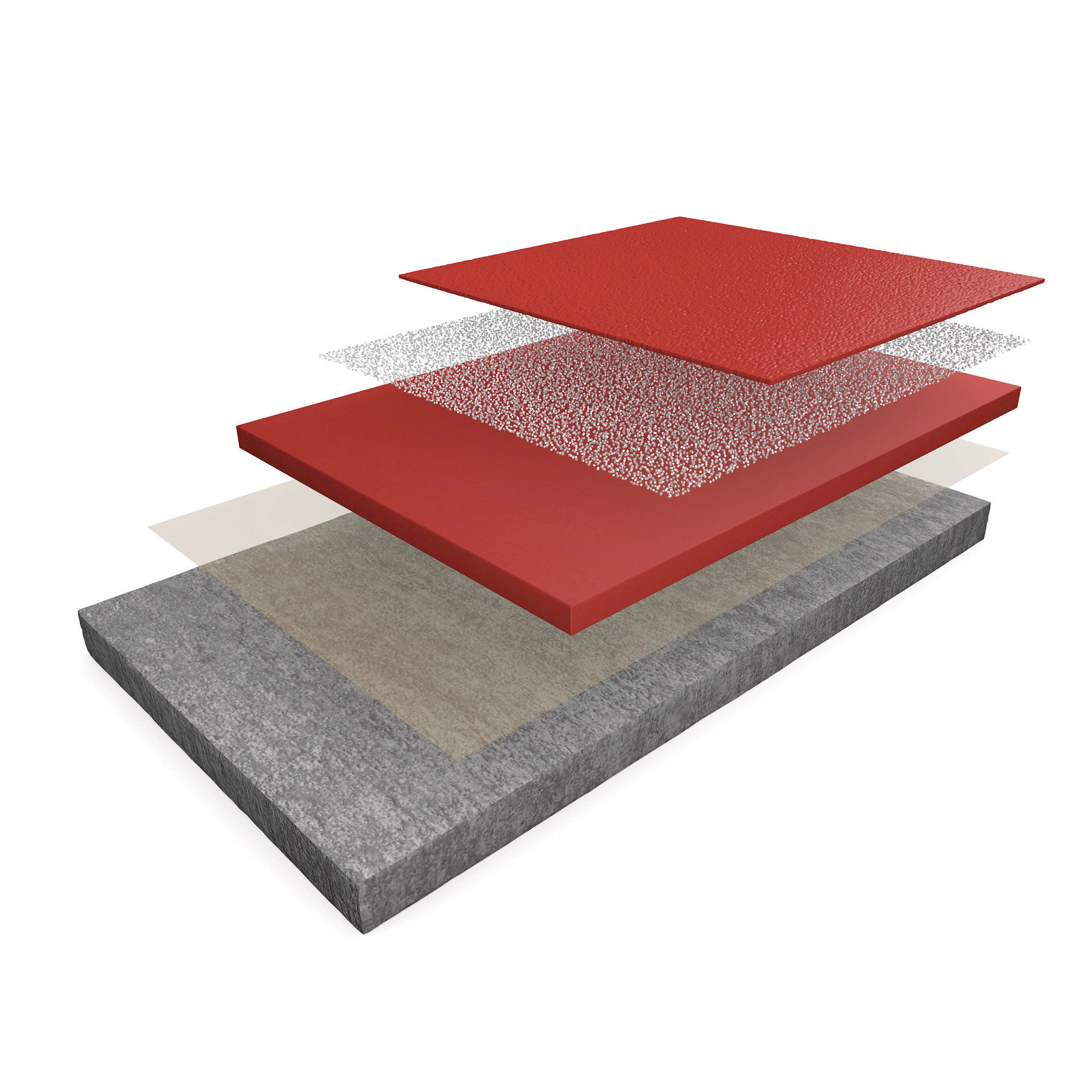

Ure-Crete™ SLB is a high-performance, 100% solids cementitious urethane flooring system designed for demanding industrial and commercial environments. This innovative solution combines the strength of cement with the flexibility and chemical resistance of urethane chemistry, creating a seamless, self-leveling floor. It delivers exceptional durability, thermal shock resistance, and moisture mitigation, eliminating the need for a primer in most cases. As a result, Ure-Crete™ SLB provides a long-lasting, low-maintenance, and safe flooring solution for facilities that require superior performance under heavy traffic and harsh conditions.

Common Challenges & Application Scenarios

Industrial and commercial floors face constant abuse that leads to costly downtime and repairs. Common pain points include:

Dusting & Degradation: Constant traffic and impact cause traditional concrete floors to dust, creating contamination and air quality issues.

Attaque chimique : Spills from oils, acids, solvents, and cleaning agents can degrade standard coatings, leading to staining, softening, and failure.

Cracking & Impact Damage: Heavy loads, forklift traffic, and thermal cycling cause cracks in rigid flooring systems, compromising integrity and creating trip hazards.

Hygiène et nettoyabilité : Porous surfaces or cracked floors harbor bacteria, mold, and dirt, making them unsuitable for facilities with strict sanitary standards.

Slippery Surfaces: Wet or oily conditions pose significant safety risks without adequate slip resistance.

Specific scenarios where Ure-Crete™ SLB excels:

Transformation des aliments et des boissons : Resists harsh sanitation chemicals, acids, and sugars while providing a seamless, easy-to-clean finish that meets USDA/FDA guidelines.

Logistics & Warehousing: Withstands extreme abrasion from pallet jacks and forklifts, and resists impact from dropped goods.

Light Manufacturing & Automotive: Handles thermal shock from hot tire pick-up and resists stains from oils, greases, and hydraulic fluids.

Commercial Kitchens & Institutional Settings: Its moisture-mitigating properties and slip-resistant texture ensure safety and durability in wet, high-traffic areas.

Solution & Key Features

Ure-Crete™ SLB directly addresses these challenges with its unique cementitious urethane formulation. Unlike brittle coating options, it offers a balanced solution.

Mechanical Durability: Provides outstanding compressive strength (9,000+ psi) and impact resistance to handle heavy loads and point impacts without cracking. Its flexibility accommodates minor substrate movement.

Résistance chimique supérieure : The urethane topcoat offers a broad range of resistance to acids, alkalis, oils, and many solvents, protecting the substrate from corrosive spills.

Sans couture et hygiénique : The fluid-applied, self-leveling system creates a monolithic surface with no grout lines or seams, preventing dirt and moisture entrapment for easy cleaning and superior hygiene.

Safety First: The broadcast quartz aggregate provides a permanent, slip-resistant texture, meeting or exceeding wet and dry coefficient of friction standards (>0.6 static, >0.42 dynamic wet).

Thermal Shock & Moisture Tolerant: Exceptional resistance to thermal cycling prevents delamination or cracking. Its body coat mitigates moisture vapor transmission, making it suitable for many problem slabs.

Aesthetic & Customizable: Available in a range of standard and custom colors. It can be finished with various topcoats (gloss, satin, matte) to meet specific aesthetic or performance needs.

Spécifications et données techniques

The performance of Ure-Crete™ SLB is verified by independent testing against recognized ASTM standards.

| Propriété | Méthode d'essai | Result / Value |

|---|---|---|

| Épaisseur du système | Nominal | 3/16″ (4.8 mm) |

| Résistance à la compression | ASTM C-579 | > 9 000 psi |

| Résistance à la traction | ASTM D-638 | > 4,200 psi |

| Résistance à la flexion | ASTM D-790 | > 5,000 psi |

| Dureté (Shore D) | ASTM D-2240 | 65 D |

| Résistance à l'abrasion | ASTM D-4060 (CS-17 Wheel) | 30 mg loss |

| Résistance aux chocs | ASTM D-3134 | Passez |

| Static COF (Dry) | ANSI B101.1 | > 0.6 |

| Dynamic COF (Wet) | ANSI A326.3 | > 0.42 |

| Teneur en COV | - | 0 g/L |

| Absorption de l'eau | ASTM D-570 | 0.04% |

Industries Served

Ure-Crete™ SLB is the trusted flooring choice for companies across diverse sectors:

Food & Beverage Processing (USDA, FDA compliant)

Pharmaceutical & Life Sciences (CIP areas, cleanability)

Light Industrial & Manufacturing

Automotive & Aerospace Facilities

Warehousing & Distribution Centers

Commercial Kitchens & Restaurants

Institutional & Educational Facilities

Parking Garages & Retail Backrooms

Installation & Professional Support

Professional installation by certified contractors is crucial for optimal performance. The key steps include:

Préparation de la surface : Concrete substrate is shot-blasted to a CSP 3-4 profile to ensure a clean, sound, and properly profiled surface—the most critical step for long-term adhesion.

Primer (If Required): In most environments, the moisture-mitigating body coat eliminates the need for a primer. For highly porous substrates, a specific primer is applied.

Basecoat & Broadcast: The cementitious urethane mortar is mixed and poured, then self-leveled with a squeegee. High-purity quartz aggregate is broadcast into the wet material to create the slip-resistant texture.

Topcoat Application: After curing and removing loose aggregate, a chemical-resistant urethane or polyurethane topcoat is applied to seal the system and provide the final finish and performance properties.

Curing: The system requires specific cure times (typically 8-24 hours for light traffic) depending on temperature before returning to full service.

Our technical support includes: pre-installation consultations, specification writing, jobsite audits, and dedicated application guidance to ensure your project’s success from slab to finish.

FAQ

Q: What is the main difference between a cementitious urethane and an epoxy floor?

A: While both are high-performance, cementitious urethane systems like Ure-Crete™ SLB offer superior flexibility, thermal shock resistance (withstands freeze-thaw cycles and hot tire pick-up), and better moisture tolerance. Epoxies are typically harder but more brittle.

Q: How long does the installation process take?

A: For a typical area, surface prep can take 1 day, with the Ure-Crete™ SLB system installation (primer, basecoat/broadcast, topcoat) completed over 2-3 days, followed by a curing period. Schedule depends on size, conditions, and system design.

Q: Can Ure-Crete™ SLB be installed over an existing concrete floor?

A: Yes, absolutely. Existing concrete must be properly prepared via mechanical shot-blasting or diamond grinding to remove contaminants and create the necessary surface profile. A moisture test is also recommended.

Q: What is the typical lifespan and maintenance required?

A: With proper installation, expect a service life of 10+ years in heavy industrial settings. Maintenance is simple: regular sweeping and occasional damp mopping with neutral pH cleaners. Avoid harsh acidic or solvent-based cleaners.

Proof & Trust

Certified Performance: Ure-Crete™ SLB is compliant with stringent Indoor Air Quality standards (CA 01350) and is formulated with 0 g/L VOCs, ensuring a safe environment for occupants.

Trusted by Industry Leaders: Our cementitious urethane flooring system is specified by top engineering firms and facility managers for critical projects where failure is not an option.

Single-Source Responsibility: We provide both the high-quality products and the technical expertise, ensuring system integrity from specification through installation.

KAIDA PAINT for Your High-Performance Flooring

Navigating the complex world of industrial flooring requires a partner with deep expertise and reliable products. KAIDA PAINT has established itself as a leading force in advanced resinous flooring systems, specializing in the development and supply of urethane and cementitious technologies like our flagship Ure-Crete™ SLB.

Our difference lies in our integrated approach. We don’t just sell paint or coating; we deliver comprehensive solutions. Our in-house chemists and technical specialists work directly with facility managers, specifiers, and a network of trained contractors to ensure every project—from a food plant requiring USDA compliance to a warehouse needing extreme durability—is backed by:

Formulation Expertise: Cutting-edge R&D focused on durability, safety, and sustainability.

Technical Authority: Unmatched support from specification through installation and maintenance.

Des performances éprouvées : Systems trusted in critical environments where failure is not an option.

Why risk your facility’s productivity and safety with an untested solution? Contact KAIDA PAINT today. Let our experts analyze your needs, provide sample pictures and finish options, and outline a system designed for longevity, helping you make an informed decision on cost and value. Request your free project consultation now.