Description

Aperçu du produit

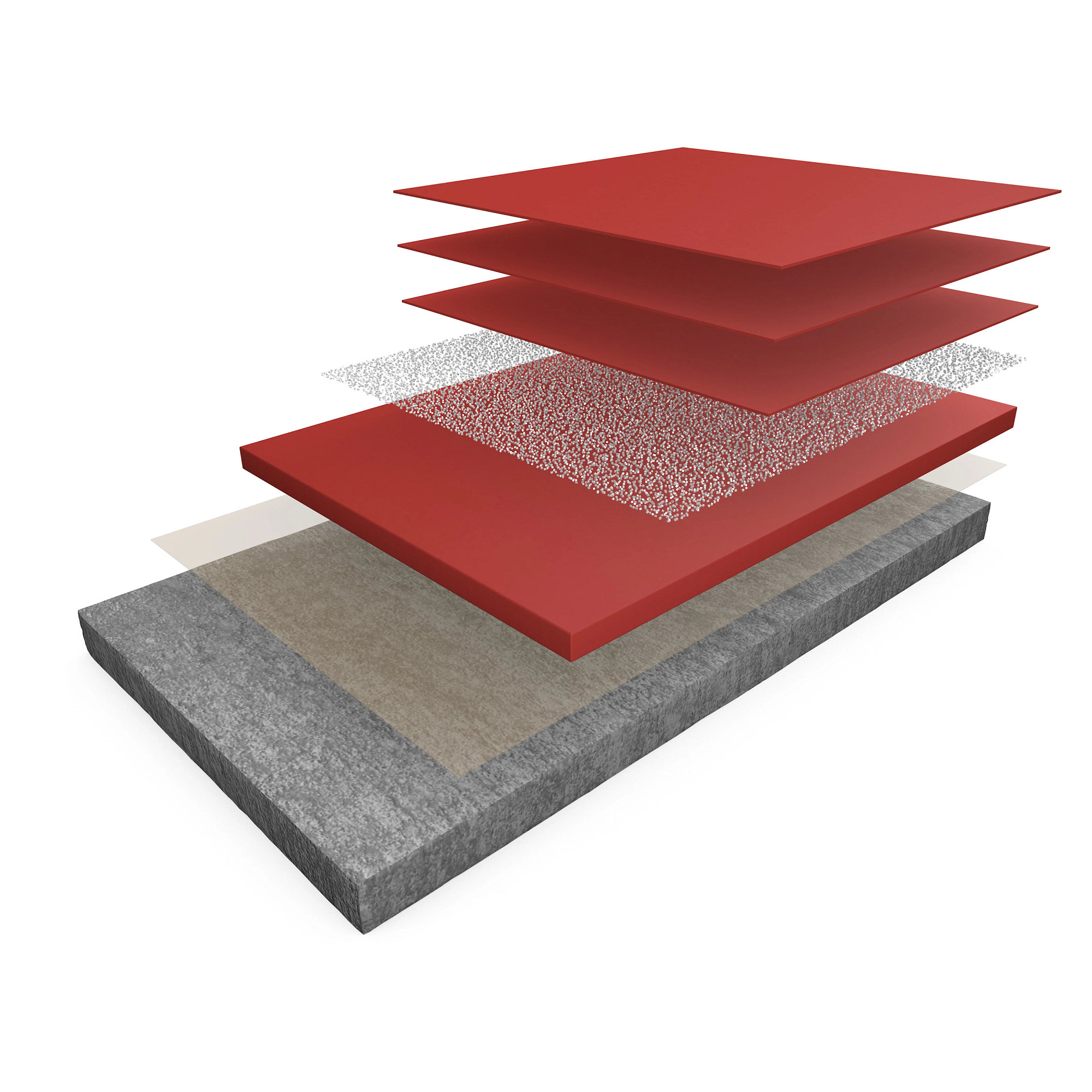

TerraFlex™ Advanced NMP Performance EV is a premier cementitious urethane flooring system engineered for the most demanding industrial environments. This seamless, fluid-applied urethane concrete solution combines a high-strength urethane mortar base with specialized polyurethane topcoats to create an exceptionally durable and chemically resistant finish. It delivers outstanding resistance to abrasion, impact, thermal shock, and critical chemicals like N-Methyl-2-pyrrolidone (NMP). Ideal for EV battery manufacturing, pharmaceutical areas, and chemical processing plants, this system provides a long-lasting, easy-to-clean, and safe industrial floor coating.

User Pain Points & Application Scenarios

Industrial and commercial facilities face constant challenges with their concrete floors. Traditional coating solutions often fail under intense stress, leading to costly downtime, repairs, and safety hazards.

Common Problems Include:

Degradation from Chemicals: Spills from acids, alkalis, solvents, and processing chemicals like NMP can rapidly degrade standard epoxy floors.

Mechanical Wear & Tear: Heavy forklift traffic, steel-wheeled carts, and dropped tools cause cracking, gouging, and dusting in inferior flooring.

Moisture & Blistering: Sub-surface moisture vapor transmission (MVT) leads to adhesive failure, bubbling, and delamination.

Slippery & Unsafe Surfaces: Inadequate slip resistance in wet or oily conditions increases the risk of workplace accidents.

Lengthy Installation Downtime: Waiting 28 days for new concrete to cure or for coatings to fully harden disrupts tight project schedules.

Critical Application Scenarios:

EV Battery & Cathode Manufacturing: Areas exposed to NMP and other aggressive solvents during cell formation and assembly require specialized products.

Transformation des aliments et des boissons : Floors must withstand frequent chemical sanitation, thermal cycling from washdowns, and heavy traffic while maintaining a hygienic, seamless surface.

Logistics & Warehousing: High-traffic aisles and loading docks need a solution that combats extreme abrasion and impact from pallet jacks and forklifts without wearing through.

Chemical Storage & Processing: Secondary containment areas and labs need reliable, impervious barriers against a wide range of aggressive substances.

Product Solution & Key Features

The TerraFlex™ Advanced NMP Performance EV system is specifically formulated to address these industrial challenges head-on. It’s more than just a paint or sealer; it’s a high-build, composite cementitious urethane coating system.

Core Advantages & Technical Specifications:

| Fonctionnalité | Benefit & Performance Data |

|---|---|

| Résistance chimique exceptionnelle | Withstands up to 14 days of continuous exposure to NMP (per ASTM D1308). Highly resistant to a wide range of acids, alkalis, fuels, and solvents. |

| Superior Mechanical Durability | Abrasion Resistance (ASTM D4060): ≤ 5.1 mg loss – 4-6x more wear-resistant than standard epoxy. Compressive Strength (ASTM C579): > 8,900 psi. Handles heavy static and dynamic loads. |

| Moisture & Substrate Tolerant | Can be applied to green concrete after just 7 days (vs. standard 28-day cure). No moisture vapor testing required. Resists osmotic blistering. |

| Sécurité renforcée | Dynamic Coefficient of Friction (DCOF): 0.72 (ANSI A326.3), significantly higher than the 0.42 industry standard for level floors, providing excellent anti-slip properties. |

| Retour rapide au service | Cures quickly, allowing light traffic in 24 hours. Full chemical resistance develops in 7 days. Enables faster project turnaround. |

| Thermal & Impact Resilience | Will not lose bond due to thermal shock. Remains flexible at low temperatures, mitigating cracking from substrate movement. Impact-resistant surface. |

| Seamless & Hygienic Finish | Creates a monolithic, non-porous surface that is easy to clean and prevents bacterial growth. Ideal for sanitary industrial environments. |

Additional Benefits for Contractors & Companies:

Low-Temperature Application: Can be installed from 40°F and rising, extending the construction season.

LEED® Contribution: Can contribute to Green Building credits (v4), appealing to environmentally conscious projects.

Color & Aesthetic Options: Available in a range of standard colors (grays, beige, red, blue, green, etc.) to meet facility marking and aesthetic needs.

Technical Data & Authoritative Standards

The performance of the TerraFlex™ system is verified through rigorous independent testing against recognized international standards, providing contractants and specifiers with trusted data.

| Propriété | Méthode d'essai | Result / Rating |

|---|---|---|

| Résistance à l'abrasion | ASTM D4060 (CS-17 Wheel, 1000 cycles) | 5.1 mg loss |

| Dureté | ASTM D2240 (Shore D) | 80 |

| Résistance à la traction | ASTM D638 | 2,175 psi |

| Résistance à la compression | ASTM C579 | 8,990 psi |

| Résistance à la flexion | ASTM D790 | 5,075 psi |

| Adhésion | ASTM D7234 | Concrete substrate failure |

| Slip Resistance (DCOF) | ANSI A326.3 | 0.72 |

| Chemical Resistance (NMP) | ASTM D1308 Method B | No Effect (14 days) |

Ideal Application Areas

This versatile cementitious urethane flooring system is specified by leading companies across diverse sectors:

Electric Vehicle (EV) & Battery Manufacturing: Formation rooms, cell assembly, cathode areas.

Pharmaceutical & Biotechnology: Cleanrooms, labs, processing areas requiring chemical resistance.

Transformation des aliments et des boissons : Production halls, packaging areas, wash-down zones.

Chemical & Industrial Processing: Plants, storage warehouses, secondary containment.

Logistics & Distribution: High-traffic warehouses, sorting centers, loading docks.

Automotive: Manufacturing plants, paint shops, repair facilities.

Installation Process & Technical Support

Professional installation is key to achieving the documented performance. The system is designed for efficiency and reliability.

Principales étapes de l'installation :

Préparation de la surface : Concrete is abrasive blasted to a CSP 4-6 profile to ensure optimal adhesion.

Optional Primer/Cove: A primer may be used, and a durable cove base can be installed at wall junctions.

Moisture-Tolerant Build Coat: The cementitious urethane mortar (Poly-Crete MD equivalent) is poured, spread to a 3/16″ thickness, and immediately broadcast with silica sand.

Grout Coat: A resin coat is applied to seal the broadcast aggregate, creating a smooth, solid substrate.

NMP-Resistant Topcoat: The final urethane or polyurethane topcoat (HPS 100 or HTS 100 equivalent) is roller-applied, providing the specified chemical, slip, and abrasion resistance.

Our Commitment: We provide comprehensive technical data sheets, installation guides, and direct access to our technical service team to support contractors from specification through project completion.

Foire aux questions (FAQ)

What is a cementitious urethane flooring system?

A cementitious urethane flooring system is a hybrid flooring solution that combines a urethane resin binder with cementitious (mortar-like) aggregates. It is troweled or poured into place, creating a thick, seamless, and exceptionally durable coating with the chemical resistance of polyurethane and the structural strength of a mortar.

How does this system compare to epoxy flooring?

While both are resinous floors, cementitious urethane systems like TerraFlex™ offer superior flexibility, abrasion resistance, and thermal shock resistance. They are less brittle than epoxy, making them ideal for areas with substrate cracking or wide temperature fluctuations. Their chemical resistance profile, especially to solvents like NMP, is also typically more robust.

What is the minimum installation temperature?

The system can be installed at temperatures as low as 40°F (4°C) and rising, offering greater flexibility than many other industrial flooring products.

How long before the floor can be put into service?

Light foot traffic is typically possible within 24 hours at 75°F. Full chemical resistance is achieved after a 7-day cure period. The rapid return to service minimizes facility downtime.

What maintenance is required?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. The seamless, non-porous finish prevents dirt entrapment and makes cleaning easy.

Proven Performance & Trust

Leading companies in the EV, pharmaceutical, and chemical sectors trust high-performance flooring systems for their critical infrastructure. Our solutions are backed by detailed technical specifications, validated test data, and a network of trained, professional contractors.

We hold our products to the highest manufacturing standards, ensuring consistency and reliability in every batch. While specific project pictures and case studies are available upon request, the performance data speaks to the system’s capability in the most challenging environments.

Your Next Step with KAIDA PAINT

For over 15 years, KAIDA PAINT has been at the forefront of innovative protective coating solutions. As a dedicated manufacturer and supplier to professional contractors, we understand that the right industrial floor is a critical asset. Our TerraFlex™ line represents our commitment to solving the toughest challenges—whether it’s prolonged chemical exposure in an EV gigafactory or relentless heavy traffic in a global logistics hub. We combine advanced polymer science with practical application expertise. Don’t just choose a product; choose a partner invested in your floor’s long-term performance.

At KAIDA PAINT, we are more than just a manufacturer; we are your partner in developing high-performance flooring solutions. With deep expertise in urethane and polyurethane chemistry, we engineer products like the TerraFlex™ Advanced NMP Performance EV to solve real-world industrial problems. Our strength lies in providing:

Tailored Solutions: We work with you to specify the right system for your specific chemical, mechanical, and environmental challenges.

Technical Expertise: Our team provides unparalleled support from initial consultation through installation.

Quality Assurance: We ensure our coatings deliver consistent, reliable performance as specified.

Ready to specify a floor that lasts? Contact our high-performance flooring experts today for a detailed quote, technical consultation, or to discuss your project requirements. Let us help you find the optimal solution for your facility’s needs.