Описание

JINYU® DT - это высокотвердое полиуретановое защитное верхнее покрытие, созданное на основе сверхтвердого белого корунда. Оно обеспечивает исключительную устойчивость к царапинам и истиранию, а его поверхностная твердость превышает 5H. Разработанное для промышленных покрытий полов, требующих максимальной долговечности, оно является идеальным решением для складов, погрузочных доков и мест с высокой проходимостью. Его формула содержит высокотвердый белый корундовый заполнитель с поверхностной твердостью более 5H и обычно используется в местах с интенсивным движением, где требуется высокая износостойкость.

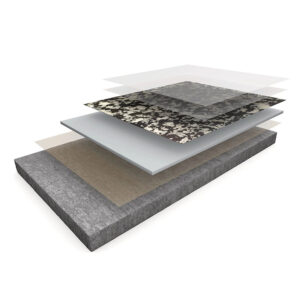

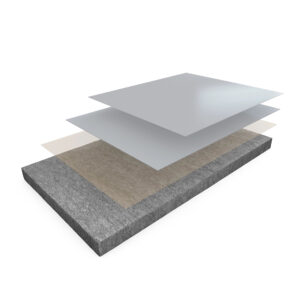

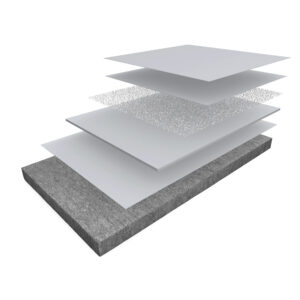

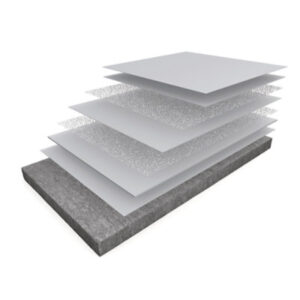

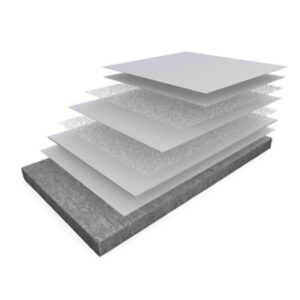

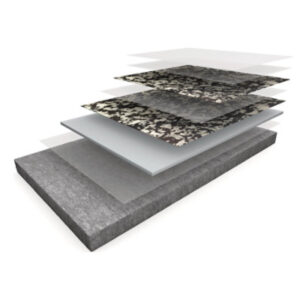

JINYU® DT следует использовать в сочетании с самовыравнивающимся полом JINYU® MF1/2 для защитных покрытий.

Области применения нашего сверхпрочного полиуретанового покрытия

JINYU® DT разработан для защиты полов в самых сложных условиях. Его превосходные характеристики делают его идеальным покрытием для полов на складах и погрузочных площадках, где постоянное истирание от вилочных погрузчиков и тяжелых грузов является ежедневной проблемой.

Помимо логистики, это отличный выбор для:

Парковка Гараж Покрытие пола: Устойчив к следам от шин, истиранию, воздействию масел и химикатов.

Напольные покрытия для супермаркетов и магазинов: Выдерживает высокую пешеходную нагрузку и движение тележек, сохраняя привлекательный полуматовый вид.

Промышленные и производственные предприятия: Обеспечивает исключительную химическую стойкость к маслам, кислотам и растворителям, защищая от разливов и пятен.

Для получения информации о других специальных сценариях, включая требования к антистатическому применению, обратитесь к специалистам JINYU®.

Ключевые особенности наших абразивостойких покрытий

Непревзойденная долговечность: Достигает твердости 5H для исключительной устойчивости к царапинам, превосходя стандартные эпоксидные и полиуретановые покрытия.

Превосходная стойкость к истиранию: Интегрированный белый корундовый заполнитель обеспечивает минимальный износ даже в условиях интенсивного движения.

Долговечная эстетика: Устойчивая к ультрафиолетовому излучению формула предотвращает пожелтение и обесцвечивание, сохраняя яркий, чистый вид на долгие годы.

Отличная химическая стойкость: Защищает от широкого спектра промышленных химикатов, масел и растворителей, что делает его настоящим химически стойким покрытием для пола.

Безопасность и комфорт: Обеспечивает полуматовое покрытие, которое уменьшает световые блики и обеспечивает достаточный коэффициент трения для безопасности.

Настраиваемые решения: Может быть использован для антистатического полиуретанового покрытия при производстве электроники и в других чувствительных средах.

Цвет

Доступно пять стандартных цветов (приблизительно):

желтый, бежевый, гуль, синий, зеленый, светло-серый, темно-серый

Пользовательские цвета могут быть заказаны в зависимости от MOQ.

Упаковка

JINYU® DT - это предварительно упакованный трехкомпонентный препарат.

Система с одним комплектом весом 10 кг:

Компонент A: 5 кг/ведро;

Компонент B: 2 кг/ведро;

Компонент C: 3 кг/пакет.

Технические параметры

Приведенные ниже данные измерены в стандартных лабораторных условиях и могут незначительно отличаться от фактических данных на месте эксплуатации.

| Артикул | Параметр |

|---|---|

| Внешний вид | После перемешивания смесь станет однородной и без комочков. |

| Твердость карандаша (устойчивость к царапинам) | 5H |

| Устойчивость к ударам (стальной шарик весом 1000 г) | Без трещин и шелушения |

| Адгезионная прочность при растяжении (стандарт) | 2,7 Н/мм² |

| Адгезионная прочность при растяжении (замачивание в воде) | 2,0 Н/мм² |

| Стойкость к истиранию (750г/500р) | 0.011g |

| Водонепроницаемость (7D) | Без пузырей, без шелушения, без обесцвечивания. |

| Устойчивость к воздействию масла (бензин 120#, 7D) | Без пузырей, без шелушения, без обесцвечивания. |

| Устойчивость к кислоте (10% H₂SO₄, 48 ч) | Без пузырей, без шелушения, без обесцвечивания. |

| Устойчивость к действию основания (30% NaOH, 48 ч) | Без пузырей, без шелушения, без обесцвечивания. |

| Устойчивость к соли (3% NaCl, 7D) | Без пузырей, без шелушения, без обесцвечивания. |

| Антискольжение (коэффициент сухого трения) | 0.55 |

Стандарт

JINYU® DT соответствует требованиям стандарта GB/T22374-2018 "Материалы для покрытия пола".

Инструкции по установке

Смешивание

Перед смешиванием тщательно перемешайте компонент А (смолу), затем в условиях низкоскоростного перемешивания (300-400 об/мин) добавьте указанную пропорцию компонента В (отвердителя) и непрерывно перемешивайте в течение примерно 30 секунд. Затем медленно добавьте компонент С (заполнитель) и перемешивайте в течение 1 минуты до получения однородной смеси.

Примечание: Компонент C является необходимым компонентом и должен быть добавлен во время перемешивания.

Применение - верхнее покрытие

Рекомендуемый расход материала для покрытия поверхности составляет от 0,1 до 0,12 кг/м2. С помощью металлического плоского шпателя равномерно нанесите материал покрытия на основание. Для обработки краевых частей используйте кисть. Толщина влажной пленки (WFT) должна контролироваться на уровне около 0,1 мм (толщина сухой пленки (DFT) составляет около 0,09 мм). Сразу же используйте валик с короткой шерстью для равномерного раскатывания и нанесения покрытия, выполняя перекрестное раскатывание в вертикальном и горизонтальном направлениях по одному разу. Это позволит добиться большей однородности и более эстетичного эффекта покрытия.

Очистка

Сразу после нанесения очистите инструменты с помощью растворителей. Пролитые материалы впитывайте сухим песком или другими абсорбирующими материалами и протирайте тряпкой.

Теоретическое потребление

0.1~0.12 кг/м2

Любое необоснованное добавление или уменьшение количества материала может повлиять на качество сопряжения, герметичность, качество склеивания, толщину покрытия и т.д. Поэтому для достижения идеальной производительности следует придерживаться рекомендуемых норм расхода и корректировать их в зависимости от реальной ситуации на месте.

Срок годности

12 месяцев с даты производства при надлежащем хранении в оригинальной, невскрытой и неповрежденной герметичной упаковке, в сухих условиях при температуре от +10 °C до +25 °C.

Часть A должна быть защищена от мороза.

Часть B должна быть защищена от мороза.

Часть C должна быть защищена от влажности.

Соотношение смешивания

Смешивание всего сырья из полного набора заводских упаковок.

Время затвердевания

| Температура | Сухая поверхность | Легкое движение | Полное излечение |

|---|---|---|---|

| +10°C | ~30h | ~48h | ~6d |

| +20°C | ~16h | ~24h | ~4d |

| +30°C | ~12h | ~18h | ~3d |

Цвет

Доступно пять стандартных цветов (приблизительно)

Желтый: RAL 1006

Красный: RAL 3002

Синий: RAL 5015

Зеленый: RAL 6001

Серый: RAL 7037

Нестандартные цвета могут быть заказаны в соответствии с минимальным количеством заказа (MOQ).