Описание

Обзор продукции

TerraFlex™ EB is a solid-color, seamless cementitious urethane mortar flooring system designed for high-traffic, demanding industrial and commercial environments. By combining the unique advantages of cementitious materials and urethane polymers, it forms a hybrid system that offers both the hardness of concrete and the flexibility of an elastomer. The system delivers exceptional wear resistance, impact resistance, and chemical tolerance, providing a durable, safe, and easy-to-clean floor coating solution for harsh scenarios such as warehouses, production workshops, pharmaceutical plants, and maintenance areas.

Common Industrial Flooring Pains and Challenges

Whether for new construction or renovation projects, choosing the wrong flooring products can lead to operational disruptions, high maintenance costs, and safety hazards. Facility managers, contractors, and engineering companies often face the following challenges:

Mechanical Damage: Heavy equipment, forklift wheels, and falling goods cause concrete cracking, dusting, and pitting.

Chemical Attack: Oils, greases, acids, alkalis, and cleaners penetrate and degrade traditional coatings, affecting hygiene and aesthetics.

Moisture Problems: Ground moisture vapor transmission causes coating blistering, delamination, and failure.

Safety Risks: Smooth surfaces become slippery when wet; uneven floors pose tripping hazards.

Hygiene and Cleaning Difficulties: Porous, cracked concrete surfaces harbor bacteria and dirt, making thorough cleaning challenging.

Aesthetics and Maintenance Costs: Floors age and fade quickly, requiring frequent repairs or complete replacement, increasing the total cost of ownership.

The TerraFlex™ EB system is engineered to address these exact challenges.

Why Choose the TerraFlex™ EB Cementitious Urethane System?

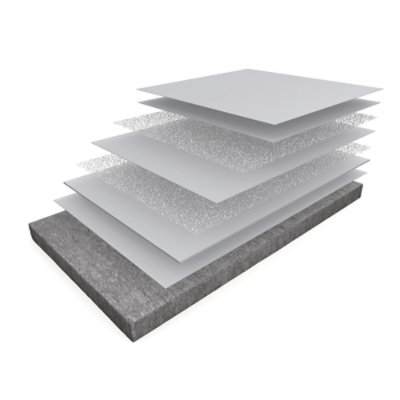

Our system is not merely a paint or sealer; it is an integrated, multi-layer solution designed for durability and performance.

1. Superior Mechanical and Physical Properties

Exceptional Abrasion Resistance: Its polyurethane topcoat (akin to polyurethane) provides outstanding wear resistance. In ASTM D4060 testing, the topcoat with anti-slip grit shows extremely low weight loss, far exceeding standard epoxy floors.

Impact and Crack Resistance: As an elastic mortar system, it absorbs and dissipates impact energy, effectively resisting cracking, making it ideal for areas with heavy object drops.

Robust Matrix: The cementitious base layer provides over 9,000 psi compressive strength and excellent adhesion, ensuring the system bonds integrally with the substrate concrete.

2. Outstanding Chemical Tolerance

The system resists many chemicals common in industrial settings, including:

Oils and Greases

Dilute Acids and Alkalis

Salt Solutions

Various Cleaners and Sanitizers

(Note: For specific chemicals, compatibility testing is recommended.)

3. Safety, Hygiene, and Aesthetics

Устойчивость к скольжению: Embedded natural quartz aggregate provides a permanent textured surface, significantly improving the coefficient of friction (static >0.6) under dry and wet conditions, meeting safety standards.

Seamless and Dense: A completely seamless surface eliminates dirt-trapping joints, enabling fast and thorough cleaning, meeting high hygiene standards in food, pharmaceutical, and other industries.

Customizable Appearance: Offers multiple standard colors (Beige, Light Grey, Charcoal, etc.) and custom color options for a uniform, professional finish.

4. Installation Advantages and Environmental Features

Broad Applicability: Can be installed directly on new concrete, rough existing slabs, and exhibits good tolerance to damp substrates.

Fast Return to Service: The system cures relatively quickly, minimizing operational downtime.

Low-VOC Options: Core components are formulated for low or zero VOC content, contributing to better indoor air quality and compliance with stringent environmental regulations.

TerraFlex™ EB Technical Data Summary

| Недвижимость | Test Standard | Typical Value / Result |

|---|---|---|

| Толщина системы | Номинальный | 1/4 inch (6mm) |

| Прочность на сжатие | ASTM C 579 | > 9 000 фунтов на кв. дюйм |

| Прочность на разрыв | ASTM D 638 | > 2,000 psi |

| Adhesion (to Concrete) | ASTM D 4541 | > 400 psi (cohesive concrete failure) |

| Abrasion Resistance (Topcoat w/ Grit) | ASTM D 4060 (CS-17 wheel, 1000g, 1000 cycles) | Very Low Wear Loss (~4-8 mg) |

| Устойчивость к ударам | MIL-D-3134 / ASTM D 2794 | > 160 inch-lbs |

| Поглощение воды | ASTM D 570 | < 0.1% |

| Service Temperature Range | – | Continuous Exposure: Up to 140°F (60°C) |

| Содержание летучих органических соединений | – | Low to Zero VOC Formulations Available |

Note: The above data is based on analogous product systems. For exact specifications, refer to the official TerraFlex™ EB Technical Data Sheet.

Primary Application Areas

The TerraFlex™ EB flooring system is widely used in venues demanding high floor performance:

Logistics & Warehousing Centers: Withstands continuous forklift traffic and goods impact.

Заводы по производству продуктов питания и напитков: Resists frequent hot/wet cleaning, chemical spills, and heavy equipment.

Pharmaceutical & Biotechnology Facilities: Meets sterile, clean, and chemical-resistant requirements.

Automotive Manufacturing & Repair Shops: Resists oils, greases, tire marks, and tool drops.

General Manufacturing & Industrial Plants: Provides durable protection for production lines, aisles, and loading bays.

Commercial Parking Garages & Ramps: Offers an abrasion-resistant, slip-resistant, and aesthetically pleasing traffic surface.

Professional Installation Process Overview

Successful installation relies on a professional crew and strict process control. KAIDA PAINT provides not only quality products but also comprehensive technical support.

Key Installation Steps:

Substrate Evaluation & Preparation: Thorough cleaning, shot blasting (to CSP 3-4 profile), ensuring a sound, dry, contaminant-free surface. Conduct moisture tests.

Primer (if required): Apply a dedicated primer on porous substrates to enhance adhesion.

Cementitious Urethane Mortar Layer & Aggregate Broadcast: Mix and trowel the cementitious urethane mortar, immediately broadcasting quartz aggregate evenly to form a strong, slip-resistant base.

Epoxy Resin Layer & Secondary Broadcast: Apply an epoxy resin layer and broadcast fine aggregate again to fill voids and add texture/thickness.

Затирка/герметик: Apply a grout coat to lock in the aggregate and create a uniform surface.

Polyurethane Topcoat: Roll on a high-performance aliphatic polyurethane topcoat, providing the final chemical resistance, abrasion resistance, and aesthetic finish.

Вылечить: Cure strictly according to product-recommended temperature and time before full service.

We recommend installation by experienced professional contractors and advise creating a mock-up area for approval before project commencement.

Часто задаваемые вопросы (FAQ)

Q1: How is TerraFlex™ EB Cementitious Urethane Flooring different from standard epoxy flooring?

A1: Key differences lie in flexibility, weather resistance, and abrasion resistance. Cementitious urethane systems offer better flexibility and impact resistance, superior UV resistance (less yellowing), and better fatigue cracking resistance under heavy loads and temperature variations. Epoxy floors are typically harder and more brittle.

Q2: How long does the system installation take?

A2: Total project duration depends on area, environmental conditions, and specific steps. A standard system typically requires 3-5 days of on-site work (including application and cure times between coats), plus substrate preparation and final full cure time (approx. 7 days for optimal performance). A detailed schedule should be created per project.

Q3: How do I maintain TerraFlex™ EB flooring to extend its lifespan?

A3: Daily maintenance is simple: regularly sweep or mop to remove dust and debris. For stains, clean with neutral or manufacturer-recommended cleaners. Avoid strong acids, alkalis, or solvents. For heavy traffic areas, periodic inspection and consideration of a maintenance topcoat after several years is advisable.

Q4: What is the minimum installation temperature?

A4: It is recommended to apply when material, air, and substrate temperatures are between 60°F (15°C) and 85°F (29°C), and the substrate temperature is at least 5°F (3°C) above the dew point. Installation at lower temperatures severely affects material flow, cure, and final performance.

About KAIDA PAINT

KAIDA PAINT is a leading manufacturer and supplier specializing in high-performance industrial and commercial flooring solutions. With deep technical expertise and extensive industry experience, we provide end-to-end services—from products to technical support—for companies, contractors, and facility managers worldwide.

We are more than just a paint supplier; we are your flooring partner. Choosing KAIDA PAINT means you get:

Высококачественные продукты: Proven, high-performance systems like TerraFlex™ EB.

Expert Technical Support: Full-cycle support from project survey and design to on-site installation guidance.

Reliable Supply Chain: Ensuring timely product delivery to keep your project on schedule.

Comprehensive After-Sales Service: Safeguarding the long-term performance of your floor.

Get Your Custom Flooring Solution

Tired of frequent floor repairs and high maintenance costs? Looking for the most reliable floor coating for your next project?

Take Action Now!

Contact the KAIDA PAINT expert team for detailed technical information on the TerraFlex™ EB cementitious urethane flooring system, a customized quote, or to schedule a free project site assessment. Let us help you create a safer, more durable, and more efficient working environment.

Information to Prepare (Optional):

Project Type (New Construction/Renovation) & Area

Existing Substrate Condition (Concrete type, age, existing coatings, etc.)

Key Performance Requirements (Abrasion, chemical resistance, slip rating, etc.)

Desired Color and Finish