Описание

Обзор продукции

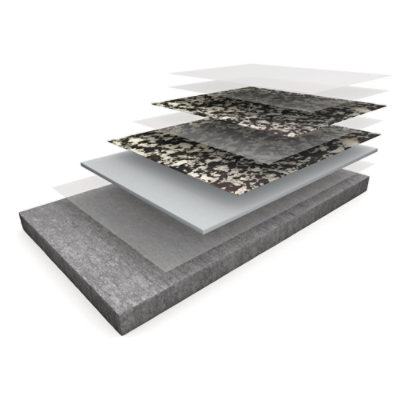

TerraFlex™ AC is a decorative, heavy-duty cementitious urethane flooring system engineered to deliver a seamless, durable, and visually appealing finish for demanding environments. This 3/16-inch seamless system incorporates a highly moisture-tolerant, self-priming, and self-leveling body coat. It is enhanced with a double broadcast of decorative Macro or Micro vinyl chips and sealed with a fast-curing topcoat, resulting in a chemical- and abrasion-resistant, high-gloss surface ideal for areas requiring both functional performance and aesthetic quality.

The Challenge: Common Industrial Flooring Problems

Industrial and commercial concrete floors face relentless daily abuse, leading to significant operational and financial headaches for facility managers, contractors, and business owners. Common issues include:

Cracking and Spalling: Heavy loads and impact from machinery cause concrete to crack and crumble, creating trip hazards and requiring costly repairs.

Dusting: Unsealed or poorly coated concrete generates constant dust, contaminating products, harming sensitive equipment, and posing health risks.

Химическая атака: Floors in food & beverage, pharmaceutical, or automotive companies are exposed to oils, greases, acids, and cleaning agents that degrade standard coatings.

Moisture Issues: Vapor transmission from subfloors can cause blisters and delamination of many flooring products.

Poor Hygiene: Porous, cracked surfaces trap dirt and bacteria, making them unsuitable for cleanrooms, laboratories, or healthcare settings.

Rapid Wear & Tear: High-traffic areas like warehouses and logistics centers suffer from rapid abrasion, leading to a worn, unprofessional appearance and frequent recoating needs.

The TerraFlex™ AC Solution: Engineered for Peak Performance

TerraFlex™ AC directly addresses these challenges with a robust set of engineered features.

1. Unmatched Durability & Mechanical Performance

Extreme Abrasion Resistance: The urethane mortar matrix offers superior wear resistance compared to standard epoxy systems, ensuring a long service life even under constant forklift and foot traffic.

High Impact Resistance: The system absorbs and dissipates impact energy, preventing cracks and chips from dropped tools or heavy equipment.

Seamless & Anti-Dust: The monolithic finish eliminates joints and pores where dirt can accumulate, creating a completely dust-free surface that is easy to maintain.

2. Superior Chemical & Environmental Resilience

Broad Chemical Resistance: Resists a wide range of chemicals including diluted acids, alkalis, oils, fats, and many solvents, protecting the concrete substrate.

Moisture-Tolerant: Can be installed on substrates with higher moisture levels (up to 99% RH per in-situ probe testing), mitigating the risk of failure due to vapor drive.

Thermal Shock Resistant: Performs reliably in environments with significant temperature fluctuations, such as freezer rooms or processing areas.

3. Functional & Aesthetic Versatility

Self-Leveling Finish: Provides a smooth, uniform surface ideal for areas requiring strict hygiene or where wheeled traffic needs a low-rolling-resistance path.

Decorative Chip Broadcast: Available with a broadcast of decorative vinyl chips (Macro or Micro size) in numerous standard and custom color blends, enhancing safety through subtle texture and improving aesthetics.

Safety Compliant: Can be formulated to meet required static and dynamic coefficient of friction (slip resistance) standards for various environments.

4. Efficient Установка & Sustainability

Rapid Cure Times: The polyurethane chemistry allows for faster return-to-service compared to some systems, minimizing facility downtime.

Low-Odor, Low-VOC: 100% solids formulation means zero VOCs, making it suitable for sensitive environments like schools, hospitals, and occupied facilities.

Долгосрочная ценность: While the initial cost may be higher than basic coatings, its exceptional longevity and reduced maintenance needs deliver a superior lifetime value.

Технические характеристики и данные

The performance of TerraFlex™ AC is backed by rigorous testing against international standards.

| Недвижимость | Метод испытания | Typical Value / Result |

|---|---|---|

| Толщина системы | Номинальный | 3/16 inch (4.8 mm) |

| Прочность на сжатие | ASTM C 579 | > 16,000 psi |

| Прочность на разрыв | ASTM D 638 | > 2,100 psi |

| Прочность на изгиб | ASTM D 790 | > 5 000 фунтов на кв. дюйм |

| Устойчивость к истиранию | ASTM D 4060 (CS-10 Wheel) | < 30 mg loss |

| Bond Strength to Concrete | ASTM D 4541 | 400 psi (substrate failure) |

| Твердость | ASTM D 2240 (Shore D) | 70 |

| Химическая стойкость | – | Excellent to oils, fats, diluted acids & alkalis |

| Содержание летучих органических соединений | – | 0 g/L (100% Solids) |

| Flame Spread Rating | ASTM E84 | Класс A |

Ideal Application Areas

TerraFlex™ AC is the specified choice for a diverse range of demanding sectors:

Обработка продуктов питания и напитков: Resists stains, chemicals, and steam cleaning; meets hygiene standards.

Pharmaceutical & Biotechnology: Seamless, cleanable, and suitable for controlled environments.

Commercial & Institutional Kitchens: Withstands thermal shock, grease, and heavy traffic.

Автомобильная и аэрокосмическая промышленность: Handles fluids, tools, and heavy rolling loads in workshops and hangars.

Warehousing & Logistics: Extremely durable for high-traffic and high-impact areas.

Парковочные гаражи: Resists de-icing salts, UV degradation (with proper topcoat), and tire abrasion.

Educational & Healthcare Facilities: Durable, safe, and low-odor for occupied buildings.

Professional Установка Process & Support

A successful flooring system depends on proper installation. The key steps for TerraFlex™ AC include:

Подготовка поверхности: Mechanical profiling via shot blasting to a CSP 3-4 profile is critical for adhesion.

Испытание на влажность: Conducting ASTM F2170 (RH probes) or ASTM F1869 tests to verify substrate conditions.

Primer Application: A cementitious primer may be used on porous substrates to ensure optimal bonding.

Base Coat & Broadcast: Application of the self-leveling cementitious urethane mortar followed by an even broadcast of colored chips.

Broadcast Seal Coat: A resin coat is applied to lock in the decorative chips.

Нанесение верхнего покрытия: A final coat of high-performance aliphatic polyurethane sealer is applied for maximum chemical and abrasion resistance and a uniform gloss.

KAIDA PAINT provides more than just products. We offer comprehensive technical support, including:

Pre-Installation Consultation and site evaluation.

Detailed Specification and material take-off assistance.

On-Site Technical Guidance for qualified contractors.

Quality Control Checklists to ensure the system is installed to specification.

Часто задаваемые вопросы (FAQ)

What is the main difference between a cementitious urethane and an epoxy flooring system?

While both are resinous systems, cementitious urethane like TerraFlex™ AC offers superior flexibility, thermal shock resistance, and moisture tolerance. It is less brittle than epoxy, making it better for environments with temperature changes or active substrates. Epoxy systems can be more rigid and may be susceptible to cracking under these conditions.

How long does the installation process take for TerraFlex™ AC?

The timeline depends on the area size and site conditions. Typically, after proper surface prep, the coating layers can be applied over 2-3 days. The system achieves walk-on hardness quickly, but full chemical and abrasion resistance develops over approximately 7 days at 70°F.

Can TerraFlex™ AC be installed over an existing floor?

Yes, it can be installed over properly prepared, sound, and contamination-free existing substrates, including concrete and certain previously coated floors. A thorough site evaluation is essential to determine feasibility.

What maintenance is required for a cementitious urethane floor?

Maintenance is simple. Regular sweeping or damp mopping with neutral pH cleaners is usually sufficient. Avoid harsh abrasive cleaners or steel wool. The durable topcoat resists staining and simplifies cleaning.

What is the typical cost range for this flooring system?

The total cost depends on project size, substrate condition, design complexity, and geographic location. As a high-performance system, it is an investment that prioritizes long-term value over the lowest initial price. Contact us for a project-specific quote.

Trust & Proven Performance

TerraFlex™ AC is trusted by leading companies worldwide.

Case Study 1: Global Food Processing Plant: Installed in a high-traffic processing area subject to thermal washdowns and chemical spills. After 5 years, the floor shows no signs of wear, staining, or degradation, ensuring continuous hygienic operation.

Case Study 2: Major Automotive Distribution Center: Replaced a worn epoxy system that cracked under constant forklift traffic. The TerraFlex™ AC system has endured 3+ years of heavy impact and abrasion without a single repair.

TerraFlex™ AC is trusted by leading companies across industries for critical flooring applications. Our products are manufactured under strict quality controls, and our technical data is validated by independent testing where applicable. We partner with a network of experienced, trained applicators to ensure every project meets the highest standards. Ask us for pictures and case studies from projects similar to yours.

Choose KAIDA PAINT for Your High-Performance Flooring Solution

At KAIDA PAINT, we are more than a manufacturer; we are your strategic partner in industrial flooring. We specialize in formulating and supplying advanced coating solutions like the TerraFlex™ AC cementitious urethane flooring system. Our expertise lies in understanding the unique challenges of industrial environments and providing contractors and facility owners with products that deliver proven performance, durability, and value.

Our Advantages:

Deep Technical Expertise: Our team provides unparalleled specification support and problem-solving.

Quality-First Manufacturing: Consistent, high-quality products you can rely on for every project.

End-to-End Project Support: From initial consultation and system design to installation guidance and follow-up.

Commitment to Innovation: Continuously improving our formulations to meet evolving industry demands.

Ready to upgrade your space with a floor that lasts? Contact the KAIDA PAINT team today for a detailed technical datasheet, color samples, or to consult with a specialist about your specific project requirements. Let us help you build a better foundation.