Descrição

Visão geral do produto

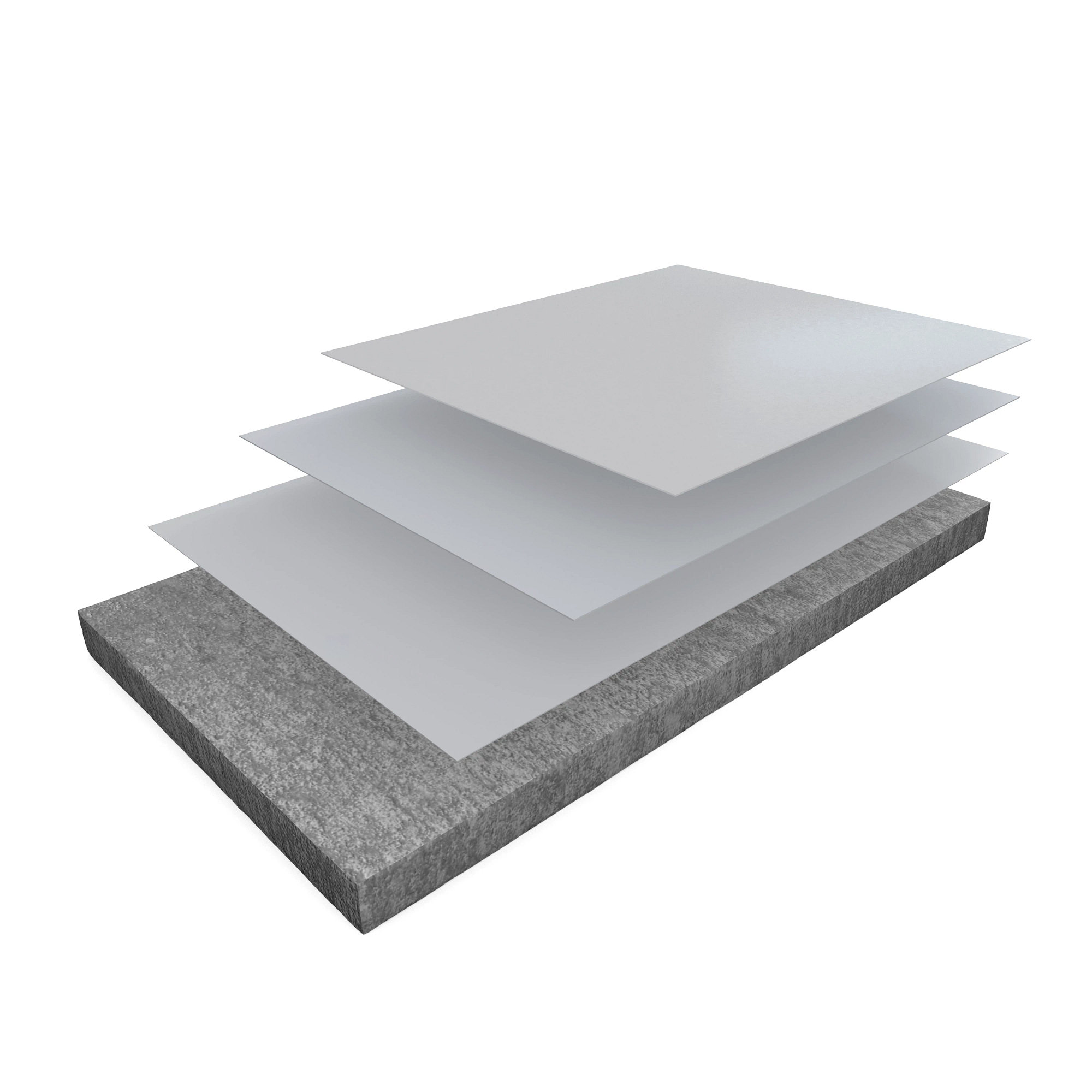

Polypro™ XT Topcoat TX is a state-of-the-art, high-performance urethane flooring system engineered for the most demanding industrial and commercial environments. This system combines advanced aliphatic polyurethane resin technology with a fortified powdered aggregate to create an exceptionally durable, abrasion-resistant, and seamless topfloor finish. It offers outstanding resistance to wear, chemicals, UV degradation, and impact, extending the lifespan of your concrete or mortar substrate far beyond that of standard epoxy or paint solutions. Designed for longevity and minimal maintenance, Polypro™ XT Topcoat TX provides a safe, easy-to-clean, and aesthetically superior coating for facilities where performance is critical.

Understanding Your Industrial Flooring Challenges

Industrial and commercial floors face relentless challenges that can compromise safety, hygiene, and operational efficiency. Common pain points include:

Premature Wear & Damage: Constant foot and wheeled traffic, impact from dropped tools or materials, and abrasive dirt lead to cracks, pitting, and dusting in inferior coating systems.

Chemical Attack: Spills from oils, greases, solvents, acids, and cleaning agents can degrade standard finishes, causing staining, softening, and delamination.

Hygiene & Cleanliness Concerns: Porous or cracked floors harbor bacteria, mold, and contaminants, making them unacceptable for food & beverage, pharmaceutical, or healthcare settings.

Safety Hazards: Slippery surfaces when wet or contaminated pose significant slip-and-fall risks for employees and visitors.

Downtime for Repairs: Frequent recoating or patching of failing floors disrupts operations and incurs repeated labor and material costs.

Specific Scenarios:

Fábricas de alimentos e bebidas: Require USDA-compliant, seamless floors that withstand daily washdowns, steam, and harsh sanitizers while resisting stains from ingredients like Betadine.

Logistics Warehouses & Distribution Centers: Need ultra-high abrasion resistance to endure constant forklift traffic, pallet dragging, and heavy rolling loads without showing wear patterns.

Automotive & Manufacturing Shops: Demand coatings that resist hot tire pick-up, hydraulic fluids, solvents, and heavy impact from equipment.

Commercial Parking Garages: Require a durable, UV-stable finish that maintains its color and gloss while resisting de-icing salts and weather cycles.

Polypro™ XT Topcoat TX: Your Comprehensive Flooring Solution

Our polyurethane flooring system is specifically formulated to address these exact challenges, providing a robust, long-lasting finish.

Core Product Features & Benefits:

Unmatched Durability & Wear Resistance:

Resistência à abrasão: Engineered with a hard aggregate filler, it wears 8-10 times better than many standard epoxy coatings, ideal for high-traffic corridors and production floors.

Mechanical Strength: Excellent tensile strength and adhesion (exceeding 350 psi with concrete substrate failure) ensure the coating withstands impact and stress without cracking or peeling.

Seamless & Monolithic: Creates a joint-free surface that eliminates dirt traps and prevents moisture ingress at seams, simplifying cleaning.

Resistência superior aos produtos químicos e às manchas:

Resists a wide range of industrial chemicals, oils, greases, and common disinfectants.

Formulated to resist staining from substances like Betadine, making it ideal for healthcare and lab environments.

Provides a non-porous barrier that protects the concrete substrate from corrosive spills.

Enhanced Safety & Functionality:

Anti-Slip Properties: The aggregate component can be tailored to provide the desired level of slip resistance (meeting R9-R11 ratings), crucial for areas that may become wet.

Easy Maintenance: The high-gloss or satin finish is resistant to scuffs and allows for quick, effective cleaning with recommended neutral or degreasing cleaners.

UV Stability: The aliphatic polyurethane resin ensures excellent color and gloss retention, preventing yellowing or chalking, which is vital for areas with natural light or exterior applications.

Application & Performance Flexibility:

Versatile Thickness: Can be applied in a range from 10 to 25 mils dry film thickness to meet specific performance requirements.

Fast Cure Times: Allows for quicker return-to-service, minimizing facility downtime. (Dry to touch in ~12 hours, light foot traffic in ~18-24 hours).

Low VOC & Water-Based Options: Available formulations support compliance with stringent indoor air quality regulations and are acceptable for use in sensitive environments.

Technical Specifications & Data

The following table outlines the typical physical properties of the Polypro™ XT Topcoat TX system, based on rigorous ASTM testing standards to ensure reliability and performance predictability.

| Imóveis | Método de ensaio | Result / Value |

|---|---|---|

| Solids Content (by weight) | – | ≥ 94% |

| Resistência à abrasão | ASTM D4060 (CS-17 Wheel, 1000 cycles) | ≤ 30 mg weight loss |

| Adhesion to Concrete | AGI 503R / ASTM D4541 | > 350 psi (100% cohesive substrate failure) |

| Resistência à tração | ASTM D638 | > 3,200 psi |

| Elongation at Break | ASTM D638 | ~25% |

| Full Cure (Chemical Exposure) | – | 7 dias |

| Recommended Service Temp | – | -40°F to +180°F (-40°C to +82°C) |

Ideal Applications for Polypro™ XT Urethane Flooring

This high-performance coating is the finish of choice across diverse sectors:

Industrial & Manufacturing: Factory floors, assembly areas, chemical plants.

Processamento de alimentos e bebidas: Meat/poultry plants, dairy facilities, breweries, kitchens.

Logistics & Warehousing: Distribution centers, loading docks, automated storage areas.

Comercial e institucional: Parking garages, stadium concourses, school hallways, hospital corridors.

Specialized Environments: Cleanrooms, laboratories, automotive service centers, aircraft hangars.

Professional Installation & Technical Support

Optimal performance of any resinous flooring system depends on proper installation. We strongly recommend using trained and certified contractors.

Principais etapas de instalação:

Preparação da superfície: Concrete must be abrasive blasted to a CSP 1-3 profile, clean, dry, and sound. Moisture vapor emission rates must be verified per ASTM standards.

Priming: Application of a compatible epoxy or urethane basecoat (e.g., at 200-250 sq ft/gal) to seal the substrate and ensure adhesion.

Optional Body Coat: For filling imperfections or building thickness, a mortar or leveling coat may be applied.

Aplicação do revestimento superior: The Polypro™ XT Topcoat is mixed with the integral aggregate and applied via roller at a rate of ~400 sq ft/gal to achieve a uniform, high-build finish.

Curing: Allow prescribed cure times before exposing to water or chemical traffic.

KAIDA PAINT provides unparalleled support: From initial site assessment and specification guidance to on-site technical assistance for our network of approved installers, we ensure your project is a success from the ground up.

Perguntas frequentes (FAQ)

1. What is Polypro™ XT Topcoat TX?

Polypro™ XT Topcoat TX is a high-performance, water-based aliphatic polyurethane floor coating system fortified with a durable aggregate. It is designed to provide an exceptionally abrasion-resistant, seamless, and chemical-resistant finish for industrial and commercial concrete floors.

2. How does it compare to standard epoxy flooring?

Polypro™ XT Topcoat TX offers 8-10 times better abrasion resistance than many standard epoxy coatings. It also provides superior UV stability (resists yellowing), better flexibility to resist thermal cracking, and enhanced resistance to certain chemicals and wear patterns in high-traffic areas.

3. Where is this flooring system best used?

It is ideal for areas subject to heavy wear, chemical exposure, and requiring high hygiene standards. Common applications include manufacturing plants, food & beverage processing facilities, warehouses, loading docks, commercial kitchens, laboratories, healthcare corridors, and parking garages.

4. What is the required floor preparation?

The concrete substrate must be clean, sound, and free of contaminants, moisture, and old coatings. It typically requires abrasive blasting to achieve a CSP 1-3 surface profile. Proper moisture testing (per ASTM standards) is mandatory before application.

5. What is the application thickness and coverage?

The system is designed to be applied at 10-25 mils (0.25-0.64 mm) total dry film thickness. The topcoat typically covers approximately 400 square feet per gallon to achieve a 4-mil wet film thickness.

6. How long does it take to install and cure?

Drying and curing times are temperature and humidity dependent. Typically, it is dry to touch in about 12 hours, ready for light foot traffic in 18-24 hours, and achieves full chemical resistance after approximately 7 days.

7. Is it slippery? Does it offer slip resistance?

The system is formulated with an aggregate that provides built-in slip resistance. The level of slip resistance can be adjusted based on the amount of aggregate used, making it suitable for environments that may become wet.

8. Is this product environmentally friendly and low-odor?

Yes. As a water-based, low-VOC (<50 g/L) formulation, Polypro™ XT Topcoat TX is more environmentally friendly than many solvent-based systems and is suitable for use in occupied facilities, including USDA-inspected food plants.

9. How do I clean and maintain a Polypro™ XT floor?

Maintenance is simple. Sweep or dust mop regularly. For cleaning, use a neutral pH floor cleaner or a mild degreaser. Avoid harsh acids, abrasive pads, or steel wool. Always rinse thoroughly after cleaning. Immediate cleanup of spills is recommended.

10. Can it be applied over an existing epoxy floor?

Yes, it can be an excellent topcoat over a properly prepared, fully cured, and profiled epoxy floor. This combination leverages the strength of the epoxy base with the enhanced surface properties of the polyurethane topcoat. A compatibility test and surface profiling are essential first steps.

Trust & Proven Performance

Polypro™ XT Topcoat TX is trusted by companies and facility managers worldwide. Our systems are specified for demanding projects because of their consistent performance and the robust technical data backing them. We adhere to strict manufacturing standards, and our produtos are developed to meet or exceed relevant industry specifications for chemical resistance, adhesion, and durability.

KAIDA PAINT Urethane Flooring Brand

At KAIDA PAINT, we are more than just a manufacturer of industrial coatings; we are your strategic partner in facility protection. With decades of expertise in urethane and epoxy resin technologies, we provide comprehensive solutions—from product formulation and technical specification support to guiding you through the selection of qualified contractors. Our commitment is to deliver a finish that not only meets but exceeds your expectations for durability, safety, and aesthetics.

Don’t let your flooring be the weak link in your operation. Explore how the Polypro™ XT Topcoat TX system can provide a superior, long-lasting coating for your concrete or cement substrates.

Request a consultation, technical data sheet, or a quote today. Let our experts help you specify the optimal flooring solution for your unique challenges.