Deskripsi

Ikhtisar Produk

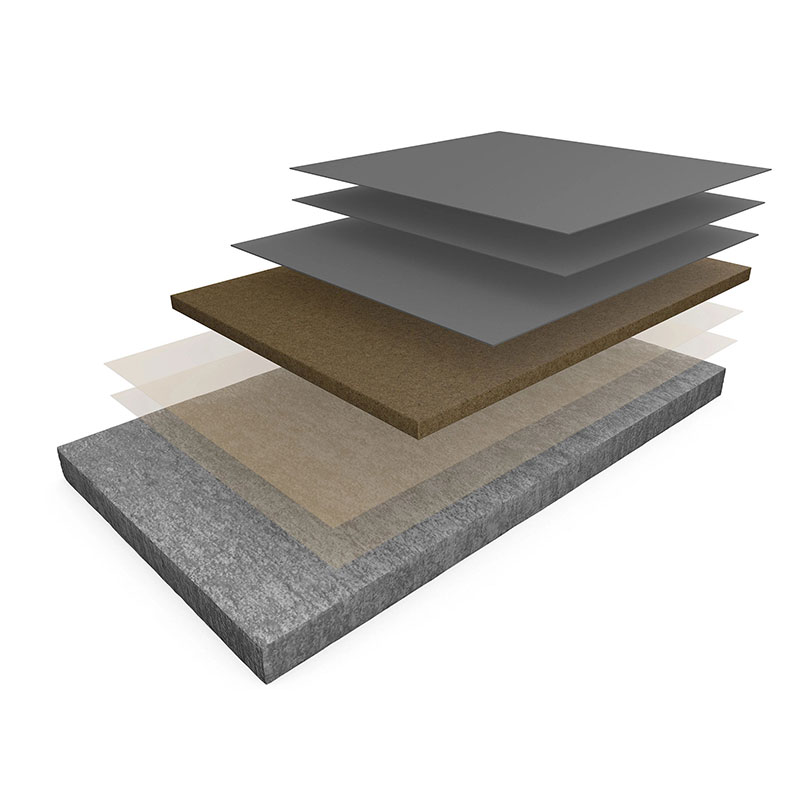

ResuShield™ Screed TG46 EV is a premium, nominal 1/4-inch thick, epoxy mortar-based resurfacing system designed specifically for demanding industrial and commercial environments. This multi-coat flooring solution combines a moisture vapor barrier, a reinforced epoxy/aggregate mortar, and a chemical-resistant urethane topcoat to create a seamless, monolithic surface. It delivers exceptional resistance to heavy impact, abrasion, and harsh chemicals like N-Methyl-2-pyrrolidone (NMP), making it the best choice for EV battery manufacturing, logistics warehouses, and processing areas. The system can be applied to green concrete, significantly reducing project timelines, and provides a slip-resistant, easy-to-clean finish that extends the life of concrete substrates.

The Industrial Flooring Challenge: Common Pain Points for Facility Managers

Companies managing industrial facilities face constant flooring challenges that impact safety, productivity, and cost:

Degradation & Damage: Constant traffic from forklifts, AGVs, and heavy equipment causes cracks, spalling, and uneven surfaces, creating trip hazards and damaging assets.

Serangan Kimia: Spills from oils, solvents, and processing chemicals (like NMP) can stain, soften, and degrade standard epoxy coatings, leading to premature failure.

Moisture Issues: Moisture vapor emission from concrete slabs can cause blistering and delamination of flooring systems, resulting in costly repairs.

Hygiene & Cleanliness: Porous or cracked floors trap dirt and bacteria, making them difficult to sanitize and failing to meet strict standards for food, pharmaceutical, or EV battery manufacturing.

Downtime & Disruption: Lengthy installation and cure times for traditional flooring cause significant operational downtime, affecting business continuity.

Our Solution: ResuShield Screed TG46 EV System Features

The ResuShield TG46 EV system is engineered to directly address these industrial challenges with a robust, multi-layered coating solution.

Unmatched Durability & Performance

Extreme Load-Bearing: With added compressive strength up to 15,000 PSI, it withstands the heaviest industrial traffic.

Superior Abrasion Resistance: ASTM D4060 testing shows abrasion resistance 4-6 times greater than standard epoxy topcoats, ensuring a long service life.

Enhanced Slip Resistance: A dynamic slip coefficient of .72 (vs. the .42 industry standard per ANSI A326.3) provides a safer finish even when wet, without compromising easy cleaning.

Advanced Chemical & Environmental Resistance

Proven NMP Resistance: Tested to ASTM D1308, the topcoat resists N-Methyl-2-pyrrolidone exposure for up to 7 days under glass, a critical feature for EV and battery facilities.

Moisture Tolerance: The integrated moisture vapor barrier (MVB) coat allows application on slabs with up to 100% relative internal humidity, protecting against vapor-related failures.

Rapid Return to Service: Can be applied to green concrete, reducing the required substrate cure time from 28 days to just 7 days, minimizing facility downtime.

Seamless & Sanitary Design

Monolithic Surface: The seamless finish eliminates joints and cracks where contaminants can hide, promoting a more hygienic environment.

Easy Maintenance: The smooth, dense surface allows for thorough cleaning and wash-downs. Spills can be easily removed without staining.

Customizable & Aesthetic

Color & Design Options: Available in standard and unlimited custom colors, including gray, white, and black, to meet design and safety coding requirements.

Functional Finishes: Options include gloss, semi-gloss, and slip-inhibiting textures to suit specific application needs.

Technical Specifications & Data

The following table summarizes key performance data for the ResuShield Screed TG46 EV system, verified through standardized testing.

| Properti | Test Method | Result / Performance |

|---|---|---|

| Chemical Resistance (NMP) | ASTM D1308 | Resistant up to 7 days under glass |

| Adhesion to Concrete | ASTM D723 | 350 psi |

| Ketahanan Abrasi | ASTM D4060 (CS-17 wheel, 1000g, 1000 cycles) | 11.7 mg loss |

| Dynamic Coefficient of Friction | ANSI A326.3 | 0.72 |

| Wet Static Coefficient of Friction | ASTM D570 (BOT 3000) | 1.81 |

| Mudah terbakar | ASTM D635 | 182 mm/min |

| Kekuatan Tekan | – | Up to 15,000 psi (added) |

| Konten VOC | EPA Method 24 | ≤ 100 g/L |

| Nominal System Thickness | – | 1/4 inch |

| Application on Green Concrete | – | Minimum 7-day cure |

Ideal Application Areas

This industrial flooring system is the specified solution for environments requiring maximum durability and chemical resistance:

EV & Battery Manufacturing: Assembly areas, drum storage rooms, and pack processing zones exposed to NMP and other chemicals.

Heavy Industrial & Warehousing: Loading docks, distribution centers, and warehouses with constant forklift and AGV traffic.

Processing & Manufacturing: Industrial plants, factory floors, and processing areas subject to impact, abrasion, and chemical spills.

Commercial & Institutional: Areas requiring a heavy-duty, easy-to-clean surface, such as commercial kitchens or utility spaces.

Professional Installation & Support

Proper installation is critical to system performance. We work with a network of qualified contractors.

Key Installation Steps:

Persiapan Permukaan: Concrete is abrasive blasted to achieve a CSP 4-6 profile, ensuring a clean, sound, and porous substrate.

Pengujian Kelembaban: In-situ probe testing per ASTM F2170 confirms moisture levels are acceptable.

Primer & Barrier Application: Resuprime MVB is applied to block moisture vapor, followed by the primer coat.

Mortar Installation: The epoxy/aggregate mortar is screeded and troweled to the specified thickness, creating a level, high-strength base.

Grout & Topcoat: A grout coat fills the mortar surface, followed by the final chemical-resistant urethane topcoat for protection and finish.

Our Commitment to Quality:

We provide comprehensive support, from specification and system design to on-site technical service, ensuring your project is completed to the highest standard.

Pertanyaan yang Sering Diajukan (FAQ)

Q: How does ResuShield Screed TG46 EV compare to a standard epoxy floor?

A: While both are resinous floorings, the TG46 EV system is a much thicker, mortar-reinforced coating with far superior abrasion resistance, impact strength, and specialized chemical resistance (e.g., to NMP). It’s designed for extreme industrial service, whereas standard epoxy is often used for lighter commercial or residential applications.

Q: How long does the installation process take?

A: The installation timeline depends on the area size and substrate condition. However, a key advantage is the ability to apply to 7-day old green concrete, bypassing the traditional 28-day cure wait. The system itself requires proper cure times between coats, typically allowing for a return to light traffic within 24-48 hours after the final topcoat.

Q: What maintenance is required for this flooring?

A: Daily dust mopping and prompt spill cleanup are recommended. For periodic deep cleaning, use a neutral pH cleaner and a brush or auto-scrubber. Avoid harsh cleaners or steel wool. The high-density surface resists staining, making maintenance simpler than porous concrete or tile.

Q: Can this system be applied over existing flooring or coatings?

A: No. The system requires application over properly prepared, sound concrete. Existing coatings, sealers, or floor coverings must be completely removed via mechanical means like shot blasting to ensure proper adhesion.

KAIDA PAINT Brand & Service Introduction:

At KAIDA PAINT, we specialize in formulating and supplying high-performance protective coatings and flooring systems for the world’s most demanding environments. As both a manufacturer and a solutions partner, we understand that a successful industrial flooring project requires more than just quality products; it needs expert specification, reliable technical support, and trusted application know-how. Our ResuShield™ line, including the Screed TG46 EV system, embodies this philosophy—delivering proven resistance, durability, and long-term value where it matters most. We work directly with facility owners, specifying engineers, and professional contractors to ensure the right system is selected and correctly installed. Let us put our expertise to work for your next industrial, commercial, or warehouse flooring project. Contact our team for a tailored specification and quote.

Why Choose Our Solution?

We are more than just a paint and coating manufacturer. As a leading provider of industrial flooring solutions, we partner with contractors and facility owners to deliver lasting results. Our products are backed by rigorous testing, detailed application instructions, and direct access to technical experts. We have successfully specified and supplied systems for major companies in the EV, logistics, and manufacturing sectors, helping them solve their toughest flooring problems.

Get Your Custom Quote & Specification Today

Ready to upgrade your facility with a flooring system built to last? Contact our team of industrial flooring specialists today. We’ll help you analyze your needs, provide detailed specifications for your contractors, and deliver the high-performance ResuShield Screed TG46 EV materials to your job site.

Request a consultation, detailed technical data sheets, or a quote for your project.