Deskripsi

Product Overview: What is ResuShield™ Cove Rez?

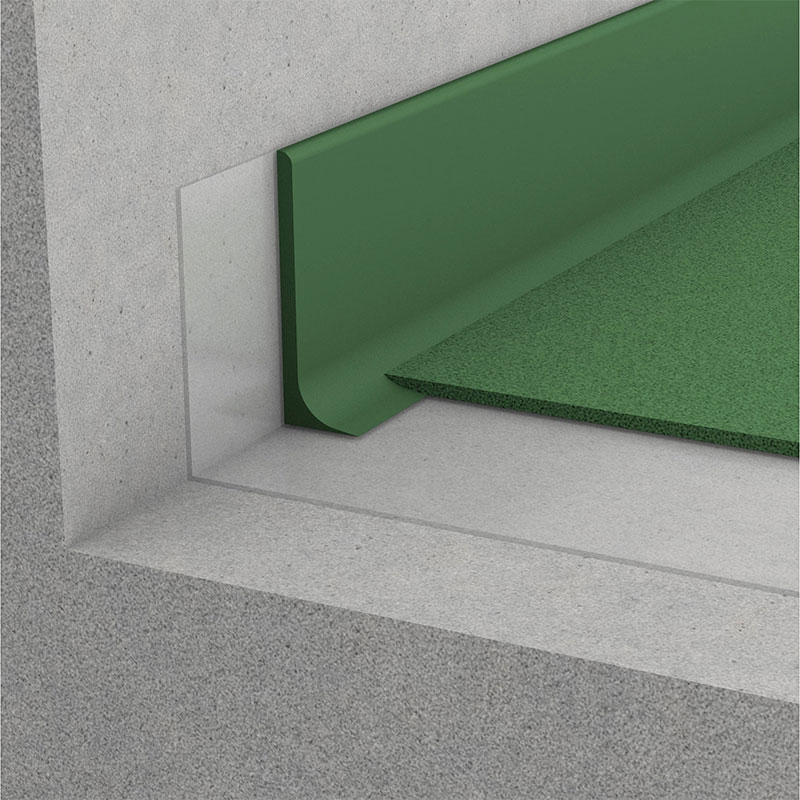

ResuShield™ Cove Rez is a high-performance, seamless epoxy cove system designed to be an integral part of a protective flooring assembly. It forms a continuous, radiused transition between the wall and the floor, eliminating corners and seams where dirt, moisture, and bacteria can accumulate. Composed of a robust epoxy resin and aggregate blend, it creates a monolithic, chemical-resistant barrier. This product offers superior resistance to impact, abrasion, and a wide range of chemicals, while being exceptionally easy to clean. It is the definitive solution for environments where hygiene, durability, and a seamless finish are non-negotiable.

Common Flooring Problems & How ResuShield™ Solves Them

Industrial and commercial floors face relentless challenges that standard paint or cement cannot withstand:

Cracks & Joints: Traditional floor-to-wall joints are weak points that crack, collect debris, and leak.

Serangan Kimia: Spills from oils, acids, sanitizers, and industrial processing chemicals degrade ordinary floors.

Hygiene Concerns: Seams and pores harbor bacteria, mold, and pests, posing risks in food, pharmaceutical, and healthcare facilities.

Mechanical Damage: Heavy traffic, impacts from dropped tools or pallets, and abrasion wear down surfaces.

Difficult Cleaning: Rough or porous surfaces trap dirt, increasing maintenance cost and effort.

The ResuShield™ Cove Rez Solution: By creating a seamless, integral cove base with a radius of up to 1 inch, it eliminates the problem joint. Its dense, non-porous epoxy matrix repels chemicals, withstands physical punishment, and provides a smooth surface that can be quickly hosed or mopped clean, directly addressing these core pain points for businesses.

Key Features & Product Benefits

Unmatched Durability & Performance

Seamless & Monolithic: No seams mean no failure points, superior hygiene, and a clean, professional appearance.

Extreme Chemical Resistance: Formulated to withstand frequent exposure to acids, alkalis, solvents, oils, and fats commonly found in kitchens, labs, and warehouses.

High Mechanical Strength: Exceptional compressive, tensile, and flexural strength (see Technical Data) resists heavy loads, impacts, and point loads without cracking.

Abrasion Resistant: The tough epoxy finish stands up to constant foot and wheeled traffic with minimal wear.

Thermal & Moisture Stability: Performs consistently across a wide temperature range and is unaffected by moisture or thermal shock.

Hygienic & Easy Maintenance

Easy to Clean: The smooth, impervious surface allows for quick and effective cleaning with standard cleaning solutions.

Slip-Resistant Options: Aggregate blend in the mortar provides traction, even when wet, enhancing safety.

Prevents Microbial Growth: The seamless design leaves nowhere for bacteria or mold to take hold.

Professional Aesthetics & Customization

Clean Finish: Achieves a smooth, gloss or semi-gloss finish that enhances ambient light and looks professional.

Color Consistency: Available in standard colors with custom color matching capabilities to fit any design scheme.

Aplikasi Serbaguna: Can be installed to any wall height (typically 4″ to 6″) with a consistent 1/4″ or 3/4″ radius cove.

Technical Specifications & Data

The following table outlines the typical physical properties of the cured ResuShield™ Cove Rez system, based on standardized ASTM testing methods, confirming its industrial-grade performance.

| Properti | Test Method | Result / Value |

|---|---|---|

| Kekerasan | ASTM D-2240 (Shore D) | 75-80 |

| Water Absorption | ASTM D-570 | 0.04% |

| Kekuatan Tarik | ASTM D-638 | 12,000 – 13,000 psi |

| Kekuatan Lentur | ASTM D-790 | 18,000 – 19,000 psi |

| Kekuatan Tekan | ASTM D-695 | 17,500 – 19,000 psi |

| Bond Strength to Concrete | ACI 503 | Concrete fails before bond loss |

| Ketahanan Abrasi | CS-10 Wheel, 1000 cycles | 30 mg weight loss |

| Mudah terbakar | ASTM D-635 | Self-extinguishing |

| Flame Spread | ASTM E-84 (NFPA-101) | Kelas A |

Primary Application Areas

The Resuflor Cove Rez system is the trusted choice across numerous sectors:

Makanan & Minuman: Meat and poultry processing plants, dairies, breweries, bottling plants, and commercial kitchens.

Pharmaceutical & Biotechnology: Cleanrooms, labs, processing areas, and sterile filling rooms.

Healthcare & Institutional: Hospital kitchens, bathrooms, showers, locker rooms, and labs.

Chemical & Industrial: Chemical production areas, packing and storage zones, and warehouses.

Logistics & Distribution: High-traffic warehouse aisles, loading docks, and coolers/freezers.

Professional Installation Process

For optimal performance, ResuShield™ Cove Rez must be installed by approved professional contractors. The key steps ensure a perfect, long-lasting finish:

Persiapan Permukaan: The concrete substrate is critical. It must be abrasive-blasted to create a profile, thoroughly cleaned, and free of contaminants, laitance, and imperfections (consult our Surface Prep Guide G-1).

Priming: A primer coat of mixed epoxy is applied to the wall and a short distance onto the floor to ensure excellent adhesion for the cove mortar.

Cove Mortar Application: The epoxy resin is mixed with a specific aggregate blend to form a mortar. This is applied vertically to the wall and formed into the desired radius cove using specialized tools lubricated with approved solvents.

Topcoat/Sealer Application: After the cove is formed, one or two coats of clear or pigmented epoxy topcoat are applied to the cove base and the entire floor. This provides the final chemical and abrasion resistance and the desired gloss level.

Curing & Cleanup: Proper temperature (50°F-90°F) and conditions are maintained during cure. All equipment is cleaned immediately with recommended solvents like xylene.

Pertanyaan yang Sering Diajukan (FAQ)

Q1: How does ResuShield™ Cove Rez differ from just painting a cove base with regular epoxy paint?

A: It is a full-system approach using a specially formulated, high-build mortar and topcoat. It provides significantly greater thickness (up to 1/4″), impact resistance, and a true monolithic, seamless structure compared to thin paint-like coatings.

Q2: What is the typical coverage and cost per square foot for this system?

A: Coverage depends on cove height and radius. The primer covers ~200 sq ft/gal, the grout/topcoat ~100 sq ft/gal. The mortar covers 40-50 linear feet per batch for a 4″ cove. Cost is project-specific; contact us for a detailed quote based on your square footage and conditions.

Q3: How long does installation take, and what is the downtime?

A: A typical project involves 1-2 days for prep, 1 day for cove installation, and 1 day for topcoat application. The floor can usually accept light foot traffic in 12-24 hours and full service/chemical exposure after a full cure (typically 3-7 days, depending on conditions).

Q4: Can this be applied over existing tile or other floors?

A: It can be applied over sound, properly prepared substrates including concrete, quarry tile, and block. A thorough assessment by our technical team or an approved installer is required to determine the correct prep and feasibility.

Why Choose Our Solution? Trust & Expertise

We don’t just supply products; we deliver confidence. Our company backs the ResuShield™ Cove Rez system with:

World-Class Technical Support: Direct access to our Technical Service Department for specification and application guidance.

Proven in Demanding Environments: Trusted by leading companies in food processing, pharmaceuticals, and industrial manufacturing.

Quality Assurance: Manufactured under strict quality controls, with performance data verified by independent ASTM standards.

Professional Network: A global network of approved, experienced contractors ensures your installation is performed to the highest standard.

KAIDA PAINT for Your High-Performance Flooring

Navigating the complex world of industrial flooring requires more than just a product supplier—it demands a technology partner you can trust. KAIDA PAINT stands at the forefront of resin-based coating innovation, specializing in formulating and delivering flooring systems that meet the rigorous demands of modern industry.

Our expertise extends beyond manufacturing. We provide comprehensive solutions, from initial facility assessment and system specification to on-site technical support for contractors during installation. The ResuShield™ Cove Rez system exemplifies our commitment: a product born from deep understanding of chemical resistance needs in food, pharma, and industrial settings, backed by verifiable performance data and unparalleled customer support.

We empower companies and contractors to achieve durable, compliant, and aesthetically pleasing results that reduce long-term maintenance costs. Whether you’re facing challenges with chemical attack, hygiene protocols, or mechanical wear, our team has the knowledge and resources to guide you to the optimal solution.

Get Your Custom Quote & Technical Specs:

Contact our flooring experts today for a free project consultation, detailed specification sheets, pictures of completed projects, and a competitive price quote tailored to your specific needs and square footage.