Deskripsi

For companies managing industrial facilities, contractors specializing in commercial builds, and facility managers, the choice of flooring is critical. Ordinary paint or cement simply cannot withstand the daily assault of heavy traffic, chemical spills, and mechanical wear. You need a solution that combines supreme durability with a professional finish.

The ResuShield™ Topcoat FX Epoxy Flooring System is engineered to be that solution. This topcoat system is not just a coating; it’s a seamless, monolithic finish designed to protect your concrete substrate for the long term, transforming it into a high-performance asset for your business.

1. Product Overview

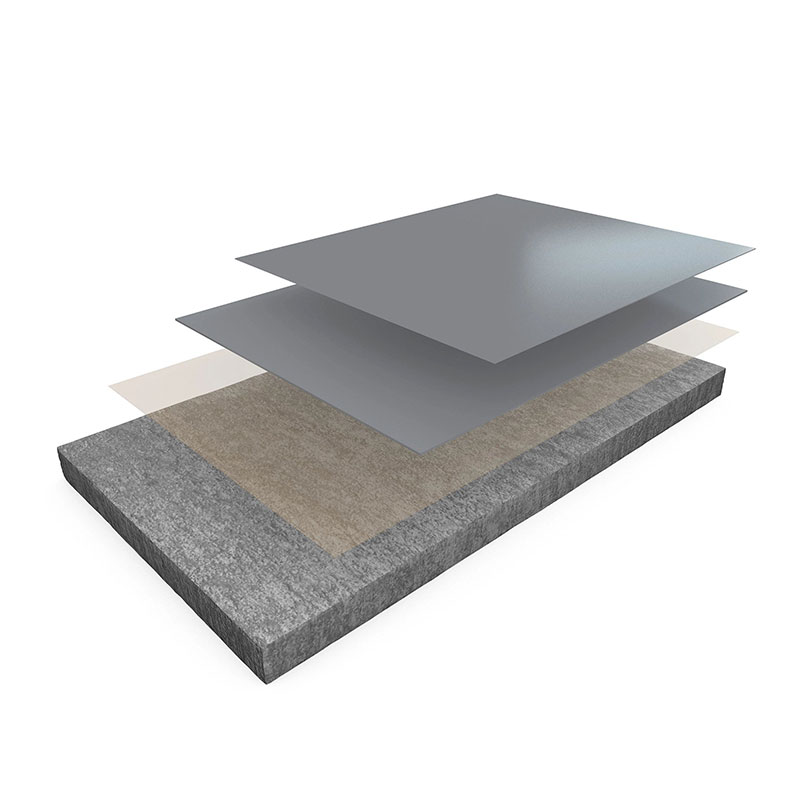

The ResuShield™ Topcoat FX is a high-build, 35-mil epoxy flooring system designed for interior concrete surfaces that demand an impact-resistant, high-gloss, and easy-to-clean finish. By combining a primer, a high-solids epoxy wearcourse, and a durable polyurethane or epoxy seal coat, it forms a seamless, impermeable barrier. This system exhibits exceptional resistance to staining, chemical attack from common acids, alkalies, fuels, grease, and salt, as well as heavy abrasion. It provides a long-lasting, easy-to-maintain flooring solution for demanding industrial, commercial, and institutional settings.

2. Common Industrial Flooring Problems & How ResuShield™ FX Solves Them

| Problem / Pain Point | Consequence | ResuShield™ Topcoat FX Solution |

|---|---|---|

| Dusting & Degradation | Unhealthy air, product contamination, constant maintenance. | Forms a seamless, non-porous topcoat that binds the surface, eliminating dusting. |

| Cracks & Spalling | Trip hazards, water ingress, further deterioration. | The 35-mil system bridges minor cracks and provides a tough, flexible shield. |

| Chemical Spills & Stains | Permanent damage, safety hazards, unsightly flooring. | Resistant to a wide range of chemicals, oils, and grease for easy cleaning. |

| Heavy Wear & Impact | Rapid wear-down from forklifts, pallet jacks, and heavy equipment. | Exceptional abrasion and impact resistance protects against chipping and gouging. |

| Difficult Cleaning & Sanitation | Increased labor cost, failure to meet hygiene standards (e.g., food processing). | High-gloss, non-porous finish allows for quick clean-up with standard cleaners. |

| Slippery When Wet | Major safety risk for employees in warehouses, kitchens, or bathrooms. | Options for slip-resistant additives (grit) can be incorporated into the topcoat. |

Application Scenarios:

Food & Beverage Plants: Withstands acidic/alkaline spills and frequent high-pressure cleaning.

Logistics Warehouses: Handles constant forklift traffic and impact from dropped goods.

Automotive Shops: Resists fuel, oil, and grease stains, simplifying repair bay maintenance.

Aircraft Hangars: Tolerant to hydraulic fluids like Skydrol™ and heavy equipment.

3. Core Features & Technical Advantages

Unmatched Durability & Performance

35-Mil System Thickness: Provides a substantial protective layer far exceeding standard paints.

Superior Abrasion Resistance: Loses only 14.9 mg per 1,000 cycles (ASTM D4060, CS-17 Wheel), ensuring a long service life.

High Impact Resistance: Exceeds demanding specifications (MIL-D-3134J), preventing damage from dropped tools or equipment.

Excellent Adhesion: Promotes concrete substrate failure before coating failure (300+ psi per ACI 503R).

Advanced Chemical & Stain Resistance

The ResuShield™ Topcoat FX system is formulated to withstand exposure to many common industrial chemicals, including:

Acids & Alkalies

Fuels & Oils

Grease & Salt

Skydrol™ Hydraulic Fluid

This makes it an ideal coating for factories, warehouses, and maintenance facilities.

Aesthetic & Functional Flexibility

High-Gloss Finish: Provides up to 90+ gloss units (60° meter) for exceptional light reflectance and a bright, professional appearance.

Color Options: Available in standard and custom colors (e.g., gray, white, tan, etc.) to match your design and safety marking schemes.

Slip-Resistant Options: Grit additives can be included to create a slip-resistant surface for areas prone to wetness.

Mulus & Higienis: The monolithic finish has no grout lines or seams, preventing dirt accumulation and facilitating sanitation.

Technical Specifications at a Glance

| Properti | Test Method | Result / Specification |

|---|---|---|

| Total System Thickness | - | 35 mils |

| Ketahanan Abrasi | ASTM D4060 (CS-17 Wheel, 1k cycles) | 14.9 mg loss |

| Resistensi Dampak | MIL-D-3134J | >160 in-lb (Direct), >110 in-lb (Reverse) |

| Adhesi | ACI 503R | >300 psi (Concrete Substrate Failure) |

| Gloss (60°) | - | 90+ |

| Heat Resistance | MIL-D-3134J | No slip/flow @ 158°F (70°C) |

| Mudah terbakar | Over Concrete | Self-extinguishing |

| Konten VOC | EPA Method 24 | <100 g/L (Compliant for industrial use) |

4. Ideal Applications for ResuShield™ Topcoat FX

This versatile flooring solution is specified by leading companies and contractors across numerous sectors:

Industrial & Manufacturing: Factory floors, plants, assembly areas.

Warehousing & Logistics: Distribution centers, loading docks, warehouse aisles.

Automotive: Service centers, repair bays, dealership showrooms.

Aviation: Aircraft hangars, maintenance bays.

Commercial Food Service: Kitchens, food processing areas, bottling plants.

Institutional: Laboratories, schools, hospital corridors.

5. Professional Installation Process

A successful installation is key to performance. KAIDA PAINT works with a network of certified installers.

Surface Preparation (Prep): Concrete is abrasive-blasted to a CSP 1-3 profile to remove contaminants and ensure perfect adhesion.

Pengujian Kelembaban: Critical tests (ASTM F1869/F2170) ensure the slab is dry and ready.

Aplikasi Primer: A dedicated epoxy primer (Resuprime™ 2468) is applied to seal and prepare the base.

Midcoat/Wearcourse: The high-build epoxy wearcourse (Resushield™ 2444) is troweled on to build thickness and strength.

Topcoat/Sealer: A final epoxy or polyurethane seal coat (Resutile™ HP5) is applied for chemical resistance and gloss.

Curing & Protection: The area is closed for a minimum of 24-48 hours for proper cure before allowing traffic.

6. Pertanyaan yang Sering Diajukan (FAQ)

Q: How does the ResuShield™ Topcoat FX system compare to standard epoxy paint?

A: Standard epoxy paint is typically a thin-film coating (3-10 mils). Our system is a 35-mil, three-component system (primer, midcoat, topcoat) designed for severe industrial duty, offering far superior thickness, abrasion resistance, impact resistance, and chemical resistance.

Q: What is the typical lead time from installation to allowing foot traffic?

A: Light foot traffic can typically resume after 24-48 hours, depending on temperature and humidity. Full cure and ability to withstand heavy industrial traffic is achieved in approximately 7-14 days.

Q: Can this flooring system be installed in a residential basement or garage?

A: While its performance is exceptional, it is engineered for commercial and industrial settings. For residential basements or garages, we offer other DIY-friendly kits and solutions that may be more cost-effective.

Q: How do I maintain and clean my ResuShield™ floor?

A: Maintenance is simple. Regular sweeping and occasional mopping with a neutral cleaner is sufficient for most areas. For heavier soiling, a cleaner/degreaser can be used. Avoid harsh chemicals and abrasive pads.

7. Why Partner with KAIDA PAINT?

KAIDA PAINT is more than just a manufacturer; we are your technical partner in flooring solutions. We provide:

Expert Specification Support: Our technical team helps you select the right system for your specific chemical and physical challenges.

Certified Installer Network: We connect you with qualified, experienced contractors to ensure a flawless installation.

Performance-Backed Products: Our products are formulated and tested to deliver the performance promised in our technical data sheets.

Global Supply Chain: Reliable supply and support for projects of any scale, from a single warehouse to a multi-city rollout.

8. Take the Next Step Towards a Superior Floor

Stop compromising on your facility’s flooring. The ResuShield™ Topcoat FX system offers a professional, long-lasting, and high-performance solution that reduces long-term maintenance cost and downtime.

Contact KAIDA PAINT today for:

A detailed technical datasheet and chemical resistance guide.

A free project consultation and quote.

Pictures and case studies from similar applications.

Referral to a certified installer in your country or city.