Deskripsi

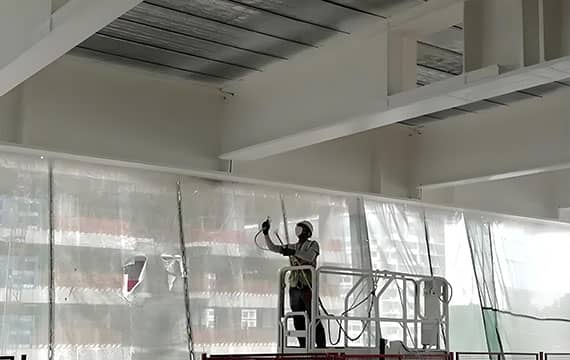

GT-NSP-Fp1.50-BTCB-2 adalah lapisan tahan api intumescent berbasis air yang dikembangkan untuk struktur baja dalam ruangan, menawarkan aplikasi film tipis, daya rekat yang kuat, ketahanan api yang sangat baik, dan hasil akhir yang dekoratif. Lapisan ramah lingkungan ini banyak digunakan untuk proteksi kebakaran pada kerangka baja dalam ruangan.

Lapisan tahan api premium ini memberikan perlindungan khusus untuk kerangka baja arsitektur modern, terutama cocok untuk proyek dengan persyaratan keselamatan kebakaran dan kualitas konstruksi yang ketat seperti kompleks komersial berskala besar, pusat transportasi, pusat data, dan fasilitas penting lainnya.

Dalam aplikasi struktur baja bertingkat tinggi, produk ini menunjukkan kemampuan beradaptasi yang luar biasa. Sifat intumescentnya yang unik membentuk penghalang termal yang padat selama insiden kebakaran, yang secara efektif menunda kenaikan suhu pada komponen baja untuk memberikan waktu yang krusial untuk operasi evakuasi dan pemadaman kebakaran.

Untuk pabrik industri dan lingkungan yang serupa, lapisan ini mempertahankan kinerja yang stabil bahkan dalam kondisi yang menantang. Formulasinya menggabungkan ketahanan terhadap api dengan perlindungan terhadap korosi, mengatasi dua masalah utama untuk struktur baja secara bersamaan. Tim teknis kami dapat memberikan solusi aplikasi yang disesuaikan berdasarkan persyaratan proyek dan faktor lingkungan tertentu.

Produk ini telah berhasil diimplementasikan di beberapa proyek penting, termasuk:

- Kerangka baja untuk terminal bandara (memberikan ketahanan api 1,5 jam)

- Komponen struktural dalam fasilitas fabrikasi semikonduktor

- Balok penyangga untuk sistem transportasi bawah tanah

- Elemen penahan beban yang kritis di pusat konvensi

Detail: (Produk ini dilengkapi label A/B tahan api - Label A ditempelkan pada drum kemasan. Hubungi kami untuk Label B.)

Fitur Utama

✔ Tahan Api 1,5 Jam - Mengembang di bawah panas untuk membentuk lapisan arang pelindung

✔ Formula Berbasis Air - VOC rendah, tidak beracun, dan aman bagi lingkungan

✔ Hasil Akhir yang Estetis - Tekstur halus dengan daya tarik dekoratif

✔ Aplikasi Mudah - Cocok untuk menyikat atau menggulung

Aplikasi:

- Bangunan komersial - Fasilitas industri - Struktur baja bertingkat tinggi

Panduan Persiapan & Aplikasi Permukaan

(1) Persiapan Substrat

- Permukaan Baja Baru

- Sandblast untuk menghilangkan karat, lalu aplikasikan:

✓ Primer kaya seng epoksi + lapisan perantara oksida besi oksida mikro epoksi

- Sandblast untuk menghilangkan karat, lalu aplikasikan:

- Baja Galvanis

- Harus diperlakukan dengan lapisan transisi epoksi sebelum aplikasi

- Permukaan Baja Tua / Permukaan yang Dicat Ulang

- Jika tidak rusak: Bersihkan dan periksa kompatibilitas lapisan

- Jika rusak: Ledakan ulang dan aplikasikan lapisan anti-korosi yang baru

- Inspeksi Pra-Aplikasi

- Verifikasi:

Cakupan primer ✓ Kebersihan permukaan (tidak ada debu/minyak)

Integritas struktural (tidak ada retakan/lasan yang buruk)

- Verifikasi:

(2) Aplikasi Pelapisan

- Pencampuran

- Aduk secara elektrik hingga merata; tambahkan air ≤5% jika diperlukan.

- Menyikat / Menggulung

- Terapkan lapisan crosshatch (≤0.2mm film kering per lintasan).

- Lingkungan

- Suhu: 5-35 ° C | Kelembaban: ≤80%

- Penguatan

- Pada ketebalan 0,8mm, sematkan jaring fiberglass bebas alkali (tumpang tindih 5-10cm).

Catatan Penting

⚠ Hindari:

- Paparan hujan selama/setelah aplikasi

- Mencampur dengan pelapis lain

- Aplikasi pada permukaan kondensasi

Penyimpanan:

Transportasi/simpan pada suhu >5°C; umur simpan: 6 bulan

Kasus Proyek: Aplikasi Pelapisan Tahan Api Pelabuhan Djibouti Proyek Pelabuhan Djibouti (2017)

menggunakan pelapis tahan api berkinerja tinggi, termasuk STI-A, BTCB-1, dan BTCB-2, untuk melindungi struktur baja yang penting di seluruh fasilitas seluas 210.000 meter persegi. Solusi kami memastikan kepatuhan terhadap standar keselamatan maritim internasional, meningkatkan ketahanan terhadap api untuk infrastruktur pelabuhan yang terpapar pada kondisi pantai yang keras. Proyek ini menunjukkan keahlian kami dalam memberikan perlindungan kebakaran yang tahan lama untuk pusat logistik berskala besar.

Kasus Proyek: Aplikasi Pelapisan Tahan Api Kilang Niger Proyek Kilang Niger (2017)

menerapkan lapisan tahan api STI-A, BTCB-1 dan BTCB-2 untuk melindungi struktur baja penting pada unit pemrosesan bersuhu tinggi. Solusi kami memberikan ketahanan api yang tahan lama melebihi perlindungan 2 jam, memenuhi standar API 2218 untuk fasilitas perminyakan sekaligus tahan terhadap iklim ekstrem Sahara. Proyek ini menunjukkan kemampuan kami dalam memberikan perlindungan kebakaran yang kuat untuk infrastruktur energi di lingkungan yang menantang.