الوصف

نظرة عامة على المنتج

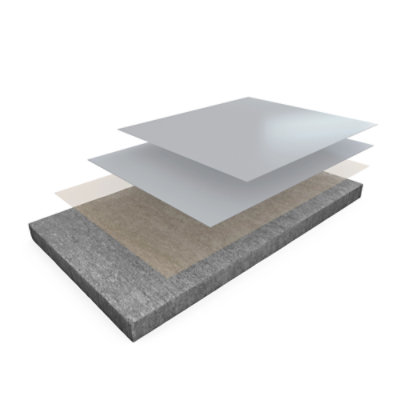

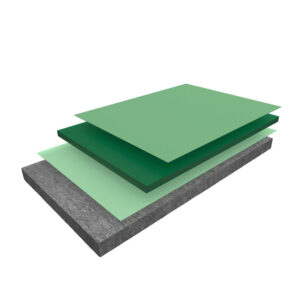

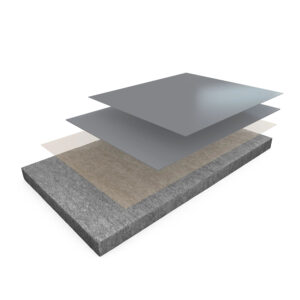

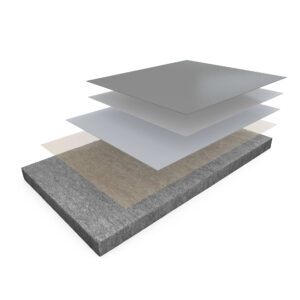

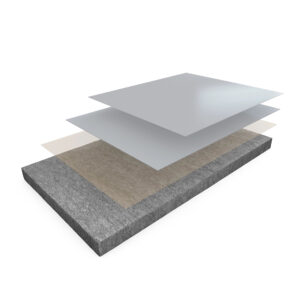

Polypro™ Performance HTS is a high-performance, three-coat urethane flooring system designed for industrial and commercial spaces subject to severe wear, chemical exposure, and constant traffic. This system combines a robust epoxy base with a superior light-stable polyurethane topcoat, creating a seamless, durable barrier that protects concrete substrates. It offers exceptional abrasion resistance, long-term chemical protection, and a satin finish that provides enhanced slip resistance. The Polypro™ Performance HTS system delivers a reliable, low-odor, and low-VOC solution for facilities requiring a finish that lasts twice as long as standard urethanes, making it the ideal coating for proactive asset protection.

The High-Cost Problem of Standard Industrial Floors

Industrial flooring faces relentless assault. Standard concrete slabs crack and dust under forklift traffic. Mortar patches fail, and cheap paint peels when exposed to oils and chemicals. For facility managers and contractors, this means:

Constant Downtime & Repair Costs: Frequent patching and recoating disrupt operations and drain budgets.

Safety Hazards: Dust from deteriorating floors affects air quality, while slick surfaces from spills increase slip-and-fall risks.

Sanitation & Compliance Issues: Porous, cracked floors harbor bacteria and contaminants, failing to meet strict standards in food, pharmaceutical, or صناعي الإعدادات.

Poor Aesthetics & Professional Image: Stained, worn floors reflect poorly on your business to clients and partners.

Whether you manage an aerospace hangar, a pharmaceutical lab, or a busy distribution warehouse, you need a flooring system that is part of the solution, not the problem.

The Polypro™ Performance HTS Solution: Engineered for Performance

Our urethane flooring system is specifically formulated to address these core industrial challenges. Here’s how:

1. Unmatched Durability & Mechanical Strength:

Superior Abrasion Resistance: With a Taber Abraser result of only 51 mg loss (ASTM D4060), the surface withstands years of heavy wheeled traffic without significant wear.

Exceptional Adhesion: The system bonds tenaciously to concrete, with adhesion strength (450-732 psi, ASTM D4541/D7234) so strong that the concrete itself fails before the coating delaminates.

High Hardness & Load-Bearing: A Shore D Hardness of 80-85 provides a tough surface that resists indentation and impact from dropped tools or equipment.

2. Advanced Chemical & Stain Resistance:

The aliphatic, moisture-cure polyurethane topcoat provides excellent resistance to a wide range of chemicals, oils, and solvents commonly found in maintenance shops, laboratories, and production areas, protecting your concrete slab from degradation.

3. Safety & Enhanced Usability:

Anti-Slip Properties: The satin finish provides a slight texture, yielding a static coefficient of friction (COF) of 0.63 (ASTM D2047), improving traction and safety underfoot.

سلس وصحي: The fluid-applied system creates a monolithic, non-porous surface with no grout lines or seams. This prevents dirt and moisture accumulation, making daily cleaning quick and effective.

Light Stable: Unlike some epoxy coatings, the polyurethane topcoat resists yellowing and degradation from UV exposure, maintaining its appearance over time.

4. Practical Installation & Performance:

Low-Odor, Low-VOC Application: Can often be applied during working hours with minimal disruption, thanks to its low volatile organic compound content (<100 g/L for the topcoat).

Fast Return to Service: The floor can typically accept light traffic within 24 hours, getting your operations back online quickly.

Customizable Aesthetics: Available in a wide palette of standard and custom colors to meet branding, safety zoning, or aesthetic preferences.

Technical Specifications Data

The performance of the Polypro™ Performance HTS system is verified by independent testing against recognized international standards.

| الممتلكات | طريقة الاختبار | Result / Value |

|---|---|---|

| مقاومة التآكل | ASTM D4060 (CS-17 Wheel, 1000 cycles) | 51 mg loss |

| Adhesion to Concrete | ASTM D4541 | 450 psi (Concrete failure) |

| Adhesion to Concrete | ASTM D7234 | 732 psi (Concrete failure) |

| الصلابة (Shore D) | ASTM D2240 | 80-85 @ 0 sec / 75-80 @ 15 sec |

| Coefficient of Friction (Dry) | ASTM D2047 (James Machine) | 0.63 |

| القابلية للاشتعال | ASTM D635 | 182 mm/min |

| System Thickness | – | Primer: 3-5 mils / Build Coat: 7-13 mils / طلاء علوي: 2-3 mils |

| VOC Content (Topcoat) | ASTM D3960 | < 100 g/L |

مجالات التطبيق

The Polypro Performance HTS urethane flooring is the trusted choice across industries:

Industrial & Manufacturing: Assembly plants, packaging areas, warehouse and distribution centers.

Automotive & Aerospace: Vehicle maintenance shops, repair bays, aerospace hangars.

Life Sciences & Healthcare: Pharmaceutical manufacturing suites, laboratories, clean rooms, educational facilities.

Commercial & Food & Beverage: Food processing areas where chemical and slip resistance is critical.

Professional Installation & Support

A successful installation hinges on proper preparation and application. We partner with a network of certified installers and provide comprehensive support.

Surface Prep: Concrete must be abrasive blasted to a CSP 1-3 profile, clean, sound, and dry.

System Application: The system is applied in three key stages: a penetrating primer (Polypro MPE), a build coat (Polypro MPE) for thickness, and the durable polyurethane topcoat (Polypro HTS 100).

Environmental Conditions: Optimal application occurs at substrate temperatures between 50°F–95°F (10°C–35°C), at least 5°F above dew point.

Our Role: From initial specification to on-site technical support, we ensure you and your contractor have the knowledge and products for a flawless, long-lasting finish.

الأسئلة الشائعة (FAQ)

Q: What is the main difference between a polyurethane and an epoxy flooring system?

A: While both are durable, polyurethane topcoats like ours offer superior flexibility, UV stability (no yellowing), and often better resistance to thermal shock and a broader range of chemicals compared to standard epoxy finishes. They are the preferred topcoat for high-performance systems.

Q: Can Polypro Performance HTS be applied over an existing epoxy floor?

A: Yes, it can be an excellent topcoat over a properly prepared and aged epoxy floor, enhancing its chemical and UV resistance. The existing coating must be thoroughly cleaned, degreased, and abraded to ensure adhesion.

Q: How long does the installation process take?

A: Project timelines vary based on area size and conditions. Typically, surface preparation takes 1-2 days, and the coating application (including cure times between coats) can take 3-5 days. Light traffic is often possible within 24 hours of the final coat.

Q: What is the expected lifespan and how do I maintain it?

A: With proper installation and care, the system can last 10+ years in heavy traffic. Daily sweeping and occasional damp mopping with a neutral pH cleaner are recommended. Avoid harsh abrasive cleaners or steel wool.

Trusted by Industry Leaders

Polypro™ systems are specified by leading companies in manufacturing, logistics, and facilities management who cannot afford downtime. Our products are backed by rigorous testing and a network of professional contractors. While we don’t share client pictures without permission, we can provide detailed case studies and project references upon request to demonstrate our proven track record in delivering reliable flooring solutions.

Kaida Paint Urethane Flooring Brand

At Kaida Paint, we are more than just a paint and coatings manufacturer. We are your partner in industrial asset protection. With decades of expertise in high-performance resinous flooring systems, including advanced epoxy and polyurethane technologies, we provide:

Technical Expertise: In-depth support for specifiers, contractors, and facility managers.

Quality-Assured Products: Consistent, reliable formulations that perform as specified.

Complete System Solutions: From primer and basecoat to the final sealer, we supply every component for a compatible, high-performing system.

Local Support: Access to our technical service team for guidance from project conception through installation.

Ready to eliminate floor problems for good? Contact Kaida Paint today for a detailed product datasheet, a system specification for your project, or to connect with a qualified Installer in your area. Let us help you calculate the true cost of ownership for a floor that protects your investment and supports your operations for years to come.

Get Your Free Consultation & Quote Now.