الوصف

For contractors, facility managers, and companies seeking a superior, durable finish for high-traffic areas, the Polypro™ Performance HPS urethane flooring system delivers unmatched performance. This three-coat, high-solids system combines the chemical resistance of epoxy with the flexibility and UV stability of a premium urethane topcoat. It’s engineered to solve the toughest challenges in industrial flooring, from chemical spills in cement plants to heavy forklift traffic in warehouses, providing a seamless, easy-to-clean, and long-lasting solution.

نظرة عامة على المنتج

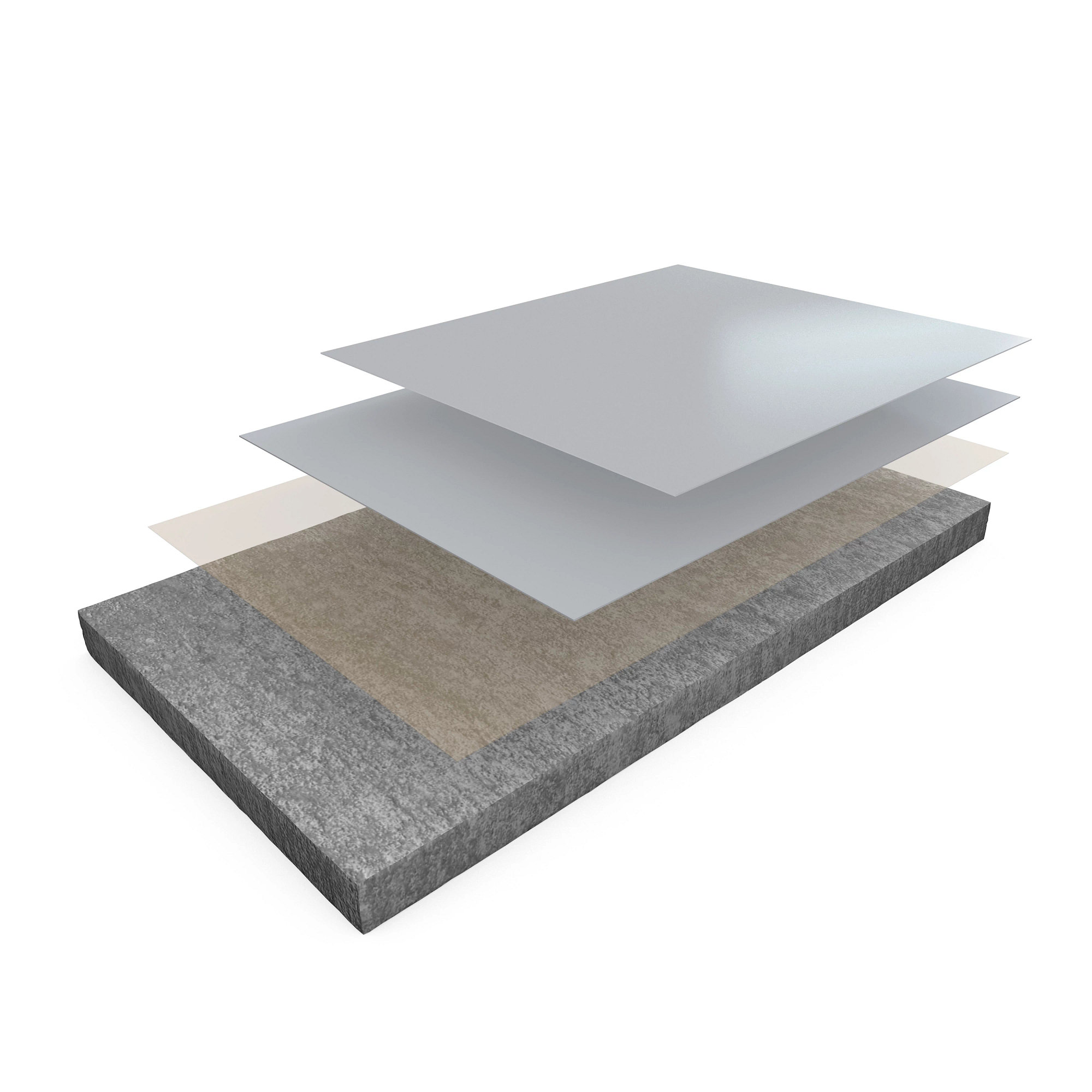

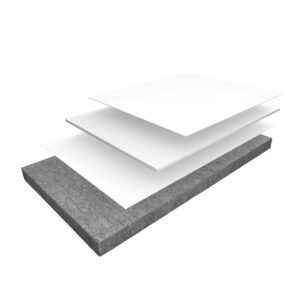

The Polypro™ Performance HPS is a urethane flooring system engineered for demanding industrial and commercial environments. Through its three-layer application—a high-build epoxy basecoat, a reinforced mortar or self-leveling layer, and a crystal-clear urethane topcoat—it forms a seamless, monolithic membrane over concrete substrates. This system offers exceptional abrasion resistance, high chemical tolerance, and a durable, high-gloss finish. It provides a robust, easy-to-maintain, and aesthetically pleasing flooring solution for facilities where performance and cleanliness are non-negotiable.

Common Industrial Flooring Problems

Where Polypro™ Performance HPS Excels

Traditional concrete floors and inferior coatings fail under stress, leading to costly downtime, safety hazards, and constant repairs. Here are the key pain points our system addresses:

Chemical Attack & Staining: Spills of oils, fuels, acids, alkalis, and cleaning agents can degrade standard paint and epoxy, causing discoloration, softening, and failure. The Polypro™ Performance HPS topcoat provides superior chemical resistance.

Heavy Abrasion & Impact: Constant traffic from steel-wheeled carts, pallet jacks, and dropped tools wears down surfaces, creating dust and rough patches. Our system’s high Taber abrasion resistance ensures longevity.

Cracking & Delamination: Substrate movement and thermal cycling cause brittle coatings to crack. Our urethane system retains flexibility, bridging minor cracks in the concrete.

Hygiene & Cleanliness Challenges: Porous or cracked floors harbor bacteria, mold, and dirt. The seamless, non-porous finish of Polypro™ Performance HPS meets strict sanitary standards for food & beverage and pharmaceutical facilities.

Slippery When Wet: Safety is paramount. The system can be installed with anti-slip aggregates to achieve desired anti slip polyurethane properties, meeting high Wet Static Coefficient of Friction (SCOF) ratings.

Specific Application Scenarios:

Food & Beverage Processing: Withstands frequent hot pressure washing, steam cleaning, and exposure to sugars, fats, and sanitizers.

Warehousing & Logistics: Endures extreme abrasion from forklifts and heavy loads without showing wear.

Automotive & Repair Shops: Resists gasoline, motor oil, brake fluid, and hydraulic fluids while being easy to clean.

Pharmaceutical & Laboratory Settings: Provides a seamless, non-porous, and chemically resistant surface that meets cGMP requirements.

Polypro™ Performance HPS: Your Comprehensive Flooring Solution

Our system isn’t just a coating; it’s a fully integrated solution designed for performance and longevity.

Core Performance Advantages:

Unmatched Durability & Mechanical Strength:

Extreme Abrasion Resistance: Outperforms standard epoxies, with a low mass loss in Taber Abraser tests (CS-17 wheel, 1000g load).

High Impact & Point Load Resistance: The flexible urethane layer absorbs impacts that would shatter rigid epoxy.

Excellent Adhesion: Bonds tenaciously to properly prepared concrete, with test results often exceeding the tensile strength of the substrate itself.

Superior Chemical & Environmental Resistance:

Broad-Spectrum Chemical Resistance: Formulated to withstand prolonged exposure to a wide range of chemicals, including dilute acids, alkalis, salts, solvents, and water.

UV & Thermal Stability: The aliphatic urethane topcoat resists yellowing and gloss loss from sunlight and maintains performance across a wide temperature range.

Water & Moisture Tolerance: Low water absorption protects the concrete substrate from within.

Enhanced Safety & Cleanability:

Customizable Slip Resistance: Can be tailored from smooth to highly textured (anti slip polyurethane coating) to meet safety standards (ANSI/NFSI B101.1) for wet and dry conditions.

Seamless & Non-Porous: Eliminates grout lines and pores where dirt and microbes hide, enabling easy, effective cleaning and sterilization.

Aesthetic Flexibility & Professional Finish:

Gloss Retention: Maintains a high-gloss, reflective finish that enhances lighting and creates a bright, professional appearance.

Color & Design Options: Available in a full spectrum of colors to match corporate branding or functional zone marking.

Technical Specifications Data

| الممتلكات | طريقة الاختبار | Typical Result | Performance Implication |

|---|---|---|---|

| مقاومة التآكل | ASTM D4060 (CS-17, 1000g, 1000 rev) | ≤ 20 mg loss | Exceptional wear life under heavy traffic. |

| Adhesion to Concrete | ASTM D7234 (Pull-Off) | > 450 psi (Concrete failure) | Superior bond strength, system is stronger than the slab. |

| قوة الشد | ASTM D2370 | > 6,000 psi | High inherent strength of the coating film. |

| Elongation at Break | ASTM D2370 | 5-10% | Provides flexibility to withstand substrate movement. |

| الصلابة | ASTM D2240 (Shore D) | 75-80 | Hard surface that resists scratching and indentation. |

| Wet Static COF | ANSI/NFSI B101.1 (BOT-3000) | > 0.60 (Customizable) | Meets or exceeds slip safety standards for level wet surfaces. |

| مقاومة المواد الكيميائية | Immersion per ASTM C413 | Excellent vs. water, oils, fuels, many acids/alkalis | Protects the floor and substrate from corrosive spills. |

Ideal Applications for Polypro™ Performance HPS

This versatile industrial flooring system is the best polyurethane floor paint solution for sectors requiring resilience, hygiene, and low maintenance.

Manufacturing & Industrial Plants

Food, Beverage & Dairy Processing

Pharmaceuticals & Biotechnology

Automotive Manufacturing & Service

Warehouses & Distribution Centers

Commercial Kitchens & Breweries

Laboratories & Educational Institutions

Parking Garages & Loading Docks

Professional Installation Process & Our Support

A flawless installation is critical to achieving the promised performance. Our process, executed by certified installers, ensures optimal results.

Site Assessment & Concrete Preparation: We conduct thorough moisture testing (ASTM F2170) and mechanically prepare the concrete (typically shot blasting to CSP 5 profile) to ensure perfect adhesion.

Primer/Basecoat Application: A proprietary epoxy or urethane primer is applied to seal the substrate and enhance bond.

Build Coat & Leveling: A mortar (for high impact areas) or self-leveling layer is applied to fill imperfections and create a smooth, strong base.

تطبيق الطلاء العلوي: The high-performance Polypro™ Performance HPS urethane topcoat is rolled or sprayed on, delivering the final chemical resistance, gloss, and durability.

Curing & Commissioning: The floor cures quickly, with light traffic possible in 24-48 hours and full cure achieved within 7 days.

Our Technical Support: We provide more than just products. Our team offers comprehensive project support, including specification guidance, on-site technical consultation for contractors, and quality assurance checks.

الأسئلة الشائعة (FAQ)

What is the main difference between urethane and epoxy flooring?

While both are durable, urethane flooring (like Polypro™ Performance HPS) offers superior UV stability (won’t yellow), better flexibility (resists cracking), and higher thermal shock resistance. Epoxy is typically harder and more rigid but can become brittle. Urethane is often the recommended topcoat over an epoxy base for the best combination of properties.

How long does a polyurethane floor coating last?

With proper installation and maintenance, a high-quality industrial polyurethane floor coating like Polypro™ Performance HPS can last 10+ years even in severe service environments, significantly outperforming standard paints and thinner coatings.

What is the minimum temperature for applying polyurethane floor coatings?

Optimal application conditions are between 65°F and 85°F (18°C – 29°C) with low humidity, as specified in the product guide. Application outside these limits can affect cure time, adhesion, and final film properties. Always consult the product data sheet and our technical team for specific project conditions.

How do I maintain a urethane floor to extend its lifespan?

Daily sweeping and periodic wet mopping with pH-neutral cleaners are recommended. Avoid harsh acids or abrasive cleaners. For heavy spills, clean promptly. Use protective pads under heavy equipment. Regular inspection and immediate repair of any damage will maximize the life of your flooring system. Refer to the provided maintenance guide for detailed procedures.

Why Industry Leaders Trust Our Flooring Systems

Our solutions are proven in the field. We have successfully completed projects for multinational manufacturers, leading food processors, and major logistics companies. Our products are backed by independent laboratory testing to relevant ASTM and ISO standards, ensuring the performance data we provide is accurate and reliable. We partner with a network of highly qualified, experienced contractors to guarantee a perfect installation every time.

Get Your Custom Quote and Technical Specification Today

At KAIDA PAINT, we specialize in formulating and delivering advanced flooring and lining solutions for the world’s most demanding environments. For over 20 years, we have partnered with contractors, companies, and facility managers to protect their assets and enhance their operations. Our Polypro™ Performance HPS urethane flooring system exemplifies this commitment—it’s not just a product, but a promise of durability, backed by our relentless R&D, stringent quality control, and unparalleled technical support.

Our advantage lies in a complete ecosystem: high-solids, low-VOC products, comprehensive system warranties, and a global network of trained installers. We understand the total cost of ownership, which is why we engineer for longevity, reducing downtime and repair expenses. Whether you’re resurfacing a garage floor or specifying a coating for a new pharmaceutical plant, KAIDA PAINT provides the expertise, the products, and the partnership to ensure success.

Ready to upgrade your facility with a floor that performs as hard as your business does? The Polypro™ Performance HPS urethane flooring system is a smart investment in safety, cleanliness, and long-term value.

Contact KAIDA PAINT Today for:

A free, on-site consultation and project assessment.

Detailed technical specifications and material data sheets.

A competitive quote tailored to your project scope.

Referrals to certified, experienced installation contractors in your area.

Stop compromising on your floors. Choose performance. Choose durability. Choose Polypro™ Performance HPS.