Descrição

Visão geral do produto

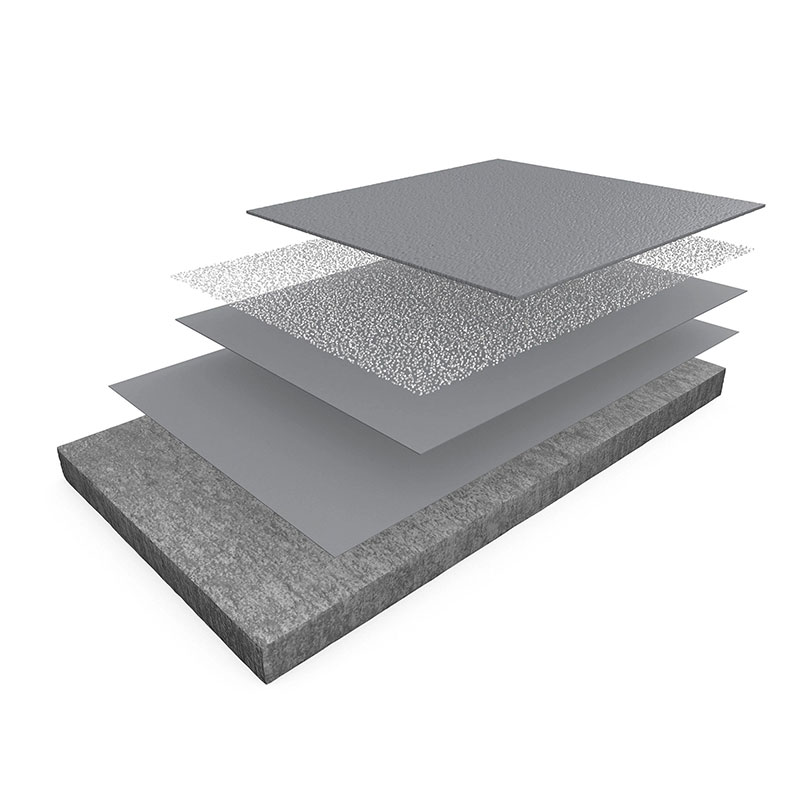

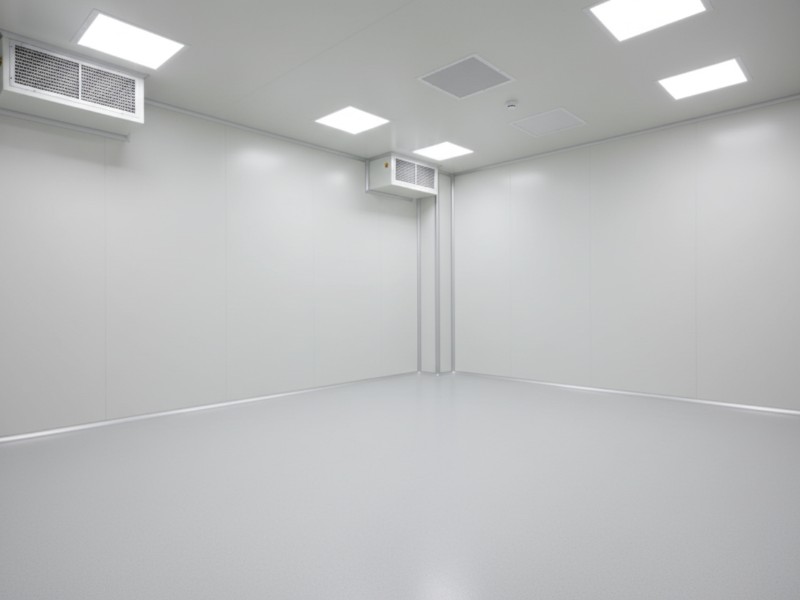

The ResuShield™ Topfloor MER I is a seamless, multi-layer epoxy flooring system designed specifically for high-traffic industrial and commercial applications. By combining a flexible, crack-bridging membrane with a broadcast wearcourse and a chemical-resistant topcoat seal, it forms a monolithic, impervious shield for your concrete substrate. This system excels in providing superior waterproofing, exceptional abrasion and impact resistance, and reliable slip resistance. Ultimately, it delivers a long-lasting, easy-to-clean finish that protects your assets and reduces long-term maintenance cost for facilities like warehouses, factories, and processing plants.

Common Industrial Flooring Problems & How ResuShield™ Solves Them

Industrial and commercial floors face relentless challenges that standard paint or cement cannot withstand.

Cracks and Structural Movement: Daily stress and substrate shifts cause hairline cracks that propagate through brittle floor coatings, leading to leaks and system failure. Our Solution: The flexible epóxi membrane in the ResuShield™ system bridges dynamic cracks, preventing them from reflecting to the surface and compromising waterproofing.

Chemical and Stain Damage: Spills from oils, solvents, and cleaning agents can permanently etch or stain ordinary floors. Our Solution: The chemically resistant topcoat provides a durable barrier against a wide range of industrial chemicals, ensuring easy cleaning and maintaining a professional appearance.

Abrasion and Impact Wear: Constant foot and equipment traffic, dropped tools, and rolling loads grind down floor surfaces, creating dust and weak spots. Our Solution: The optional aggregate-reinforced wearcourse significantly increases the system’s hardness and durability, offering outstanding protection against wear and impact.

Moisture and Water Damage: Water vapor emission or fluid spills can delaminate coatings and damage the concrete subfloor. Our Solution: The integral waterproofing membrane creates a continuous barrier, making the system ideal for basements, locker rooms, showers, and food processing areas.

Safety Hazards: Slippery surfaces when wet or soiled pose a significant risk. Our Solution:* The textured finish, achievable through aggregate broadcasting, provides a slip-resistant surface that enhances safety without sacrificing cleanability.

Detailed Product Features & Benefits

1. Unmatched Durability & Mechanical Performance

The ResuShield™ Topfloor MER I system is built to last. Its composite structure delivers:

Crack Bridging: Flexibility to absorb substrate movement without cracking.

Elevada resistência à abrasão: Withstands the punishing wear from wheels and foot traffic.

Superior Impact Resistance: Protects your subfloor from heavy dropped objects.

Seamless Monolithic Surface: Eliminates joints where dirt and moisture can accumulate, promoting hygiene and easy cleaning.

2. Superior Chemical & Stain Resistance

Engineered to perform in harsh environments, the topcoat resists degradation from:

Óleos e massas lubrificantes

Mild Acids and Alkalis

Solvents and Fuels

Common Cleaning Solutions

This resistance simplifies maintenance and preserves the floor’s aesthetic appeal in industrial kitchens, laboratories, and garages.

3. Safety & Functional Advantages

Slip-Resistant Options: Customizable surface textures (R9-R10) provide safety in wet areas.

Waterproof Integrity: A fully bonded membrane prevents water ingress, protecting the slab.

Hygienic & Easy to Clean: The non-porous, seamless surface prevents bacterial growth and allows for quick wash-downs.

4. Aesthetic Flexibility & Customization

Move beyond dull gray concrete. Choose from:

A range of standard and custom colors (grays, whites, etc.).

Various finish types: from utilitarian to decorative with flake broadcast options.

Different gloss levels (gloss, semi-gloss, satin) to suit your design needs.

Technical Specifications & Data

| Imóveis | Método de ensaio | Result/Performance |

|---|---|---|

| Espessura do sistema | – | 32 mils (approx.) |

| Dureza | ASTM D 2240 (Shore D) | 50 |

| Resistência à tração | ASTM D 412 | 1,700 psi |

| Elongation | ASTM D 412 | 80% |

| Adhesion to Concrete | ACI 503R | 300 psi (concrete failure) |

| Resistência à abrasão | ASTM D 4060, CS-17 Wheel | 14.9 mg loss (1,000 cycles) |

| Resistência química | – | Excellent to oils, greases, mild acids/alkalis |

| Inflamabilidade | – | Auto-extinção sobre betão |

| Resistência ao choque térmico | ASTM C 884 (-21°C to 25°C) | No cracking |

Ideal Application Areas

The ResuShield™ Topfloor MER I system is the best choice for a wide array of demanding settings:

Industrial & Manufacturing: Factory floors, warehouses, loading docks, repair bays.

Comercial e institucional: Mechanical equipment rooms, computer server rooms, locker rooms, showers.

Alimentação e bebidas: Processing areas, packaging rooms, wet kitchens (subject to specific regulatory approval).

Automotive: Service centers, garages, detailing bays.

Logistics & Distribution: High-traffic warehousing, sorting facilities.

Professional Installation Process

Proper installation is key to performance. Our certified contractors follow a meticulous process:

Surface Preparation (Prep): Concrete is abrasive-blasted to a CSP 3-5 profile to ensure perfect adhesion. Moisture and pH tests are conducted.

Primer/Basecoat: A primer may be applied to prepared, dry concrete to enhance bonding.

Membrane Application: The crack-bridging epoxy membrane (ResuShield™ 2444) is applied at 80 sq. ft./gal.

Wearcourse Application: A second coat of epoxy is applied (130 sq. ft./gal) and immediately broadcast with silica sand or hard aggregate for added durability and slip resistance.

Seal Coat (Topcoat): After removing excess aggregate, a chemical-resistant sealer is applied as the final topcoat, providing a seamless, protective finish.

Cura e proteção: The floor is allowed to cure fully (typically 24-72 hours for light traffic) before being put into service.

Nota: This system requires professional installation by trained contractors. DIY application is not recommended for optimal results.

Perguntas frequentes (FAQ)

What is the main advantage of ResuShield™ over standard epoxy floors?

The key advantage is its combined flexibility and durability. Unlike brittle standard epoxies, its flexible membrane bridges substrate cracks, while the aggregate-reinforced wearcourse provides exceptional abrasion and impact resistance, making it a more robust, long-term solution for dynamic industrial environments.

How long does the installation take and what’s the typical cost per square foot?

Installation time depends on area size and substrate condition. A typical project can take 3-5 days. The cost per square foot varies based on project scope, preparation needs, and chosen options (e.g., aggregate type). For an accurate quote, contact us for a site assessment.

Can it be installed over existing tile or painted concrete?

It can be applied over some sound, properly prepared existing surfaces. However, all existing coatings, paint, or tile must be thoroughly profiled and tested for adhesion. Existing sealers or waxes must be completely removed. Our technical team can advise on your specific substrate.

How do I clean and maintain a ResuShield™ floor?

Routine cleaning is simple. Use a mild detergent and a bristled brush or automatic scrubber. For oil or grease, use a dedicated cleaner/degreaser. Avoid harsh acids or abrasive pads. Periodic re-application of the seal coat can rejuvenate the appearance and extend the floor’s life.

KAIDA PAINT Introduction

At KAIDA PAINT, we are more than just a coatings manufacturer; we are your dedicated partner in building durable, safe, and efficient facilities. Specializing in high-performance resinous flooring solutions, we understand the critical demands of industrial and commercial environments. Our ResuShield™ product line, including the flagship Topfloor MER I system, is formulated based on decades of expertise and rigorous R&D, ensuring each component delivers on its promise of protection and longevity.

Our advantage lies in a holistic approach: world-class products backed by unmatched technical service. From initial site assessment and system specification to detailed application guidance and installer certification, our team supports your project every step of the way. We serve a global network of contractors, companies, and facility managers, helping them solve complex flooring challenges with reliable, cost-effective solutions.

Whether you’re battling crack reflection in a warehouse, chemical spills in a processing plant, or moisture in a basement facility, KAIDA PAINT has the expertise and the product to secure your investment. Let’s discuss your project requirements. Contact our technical specialists today for a free consultation and a tailored solution quote.