Descrição

For companies, contractors, and facility managers seeking a stunning, durable, and high-performance flooring solution, the choice is clear. The ResuShield™ Topcoat Metallic II epoxy flooring system combines industrial-grade resilience with breathtaking, custom aesthetic appeal. This seamless coating is designed for commercial and industrial environments where performance meets design, offering superior resistance to chemicals, abrasion, and impact. From warehouses and production facilities to high-traffic retail spaces and healthcare buildings, this system delivers a long-lasting, easy-to-clean finish that protects your concrete substrate while transforming its appearance.

Visão geral do produto

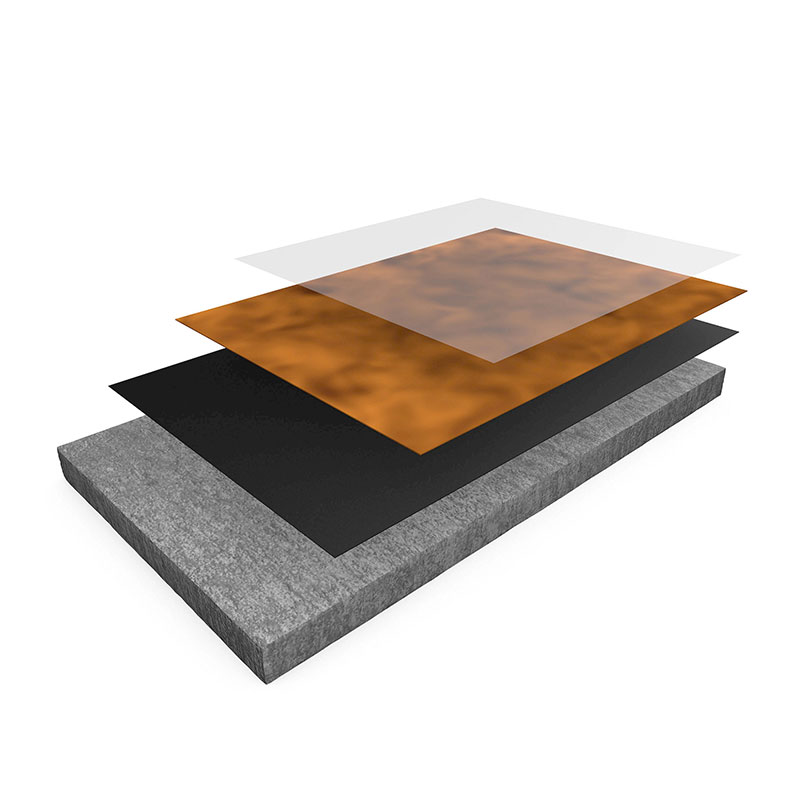

ResuShield™ Topcoat Metallic II is a state-of-the-art, multi-layer decorative epoxy flooring system engineered for demanding commercial and industrial applications. Through the strategic layering of a high-solids epoxy primer, a pigmented basecoat, a translucent metallic coat, and a durable urethane topcoat, it forms a seamless, integrated shield for your concrete floor. This system boasts exceptional mechanical durability, chemical resistance, and a unique, stone-like visual depth. It provides a cost-effective, high-value solution for facilities prioritizing hygiene, safety, and aesthetic excellence without compromising on floor coating performance.

Common Flooring Problems & How ResuShield™ Solves Them

Industrial and commercial floors face relentless challenges. Traditional coatings like standard paint or cheap sealers quickly fail, leading to costly repairs and downtime.

Cracking & Chipping: Heavy traffic and impact shatter weak finishes. ResuShield’s flexible, high-tensile-strength epoxy system resists cracking, shielding your concrete base.

Poeira e degradação: Untreated or poorly sealed cement floors constantly create dust, contaminating products and air quality. Our seamless coating permanently seals the surface.

Chemical Damage & Staining: Spills of oils, solvents, and cleaning agents eat away at standard flooring. This system offers proven chemical resistance, ensuring easy cleaning and longevity.

Slippery, Unsafe Surfaces: Wet areas become hazard zones. The optional topcoat formulations enhance slip resistance for safer bathrooms, kitchens, and processing areas.

Dull, Uninspiring Appearance: Gray concrete is bad for business morale and customer impression. The metallic coat creates a dynamic, custom look that elevates any space, from a sterile lab to a stylish hotel lobby.

ResuShield™ Topcoat Metallic II: Core Features & Benefits

Unmatched Durability & Performance

This isn’t just a floor paint; it’s a complete system. The resin-based formulation creates a bond stronger than the concrete itself.

Resistência mecânica superior: With a tensile strength of 8,000 psi (ASTM D2370) and outstanding adhesion (450+ psi, ASTM D4541), it withstands heavy wheeled traffic and impact.

Exceptional Abrasion Resistance: Independent testing shows minimal material loss (5.1 mg) under the rigorous Taber Abraser test (ASTM D4060), meaning it lasts years longer than alternatives.

Resistência química comprovada: The topcoat shield provides a robust barrier against a wide range of chemicals, oils, and stains, simplifying daily cleaning and maintenance.

Stunning, Customizable Aesthetics

Move beyond basic gray. This system delivers a high-design finish at an industrial strength.

Unique Metallic Effect: Semi-transparent metallic pigments are suspended in a UV-resistant epoxy, creating deep, pearlescent patterns that mimic natural stone or marble. No two installations are exactly alike.

Color & Design Flexibility: The pigmented basecoat serves as your canvas. Choose from light colors like white or gray for a bright finish, or darker shades for a dramatic, sophisticated look. It complements any commercial design.

Professional Finish Options: Choose between a satin (HTS-100) or gloss (HPS-100) urethane topcoat to achieve the exact sheen and slip resistance required for your application.

Practical & Hygienic Advantages

A floor should work for you, not against you.

100% Seamless & Non-Porous: Eliminates grout lines, cracks, and pores where dirt, moisture, and bacteria hide. Ideal for facilities requiring strict hygiene, like food processing or pharmaceutical plants.

Easy to Clean & Maintain: Spills wipe up easily. Routine cleaning with compatible solutions keeps the floor looking new, reducing long-term maintenance costs.

Rapid Installation & Minimal Disruption: Applied by professional contractors, the system can be installed efficiently with proper preparation, getting your business back in operation quickly.

Technical Specifications & Data

| Imóveis | Método de ensaio | Result / Value |

|---|---|---|

| Resistência à tração | ASTM D 2370 | 8,000 psi |

| Adhesion to Concrete | ASTM D 4541 | 450 psi (concrete substrate fails) |

| Adhesion to Concrete | ASTM D 7234 | 732 psi (concrete substrate fails) |

| Shore Hardness | ASTM D 2240 | 80-85 @ 1 sec / 75-80 @ 15 sec |

| Resistência à abrasão | ASTM D 4060 (CS-17 wheel, 1kg load) | 5.1 mg loss |

| Inflamabilidade | ASTM D 635 | 182 mm/min |

| Espessura total do sistema | Nominal | ~27 mils |

| Topcoat Coverage | Resutile HTS-100 / HPS-100 | 500 sq ft per gallon kit |

Ideal Application Areas

This versatile system is the best solution for countless environments:

Comercial e retalhista: Supermarkets, shopping malls, showrooms, hotel lobbies, and restaurants where aesthetics and durability intersect.

Institutional & Healthcare: Schools, universities, hospitals, laboratories, and locker rooms requiring hygienic, easy-to-clean surfaces.

Industrial & Manufacturing: Warehouses, logistics centers, food & beverage plants, and clean rooms needing chemical and abrasion resistance.

Automotive & Service: Repair shops, showrooms, and parts departments where resistance to oil, grease, and tire traffic is critical.

Public & Recreational: Airports, arenas, sports complexes, and parks that endure high foot traffic and require long-lasting beauty.

Professional Installation Process

Optimal performance requires expert application. Our network of approved contractors ensures every project meets the highest standards.

Surface Preparation & Repair: Concrete is abrasive-blasted to a CSP 3-4 profile. All cracks are filled, and the slab is tested for moisture. Proper prep is 90% of a successful install.

Aplicação de primário: ResuShield MPE primer is applied to seal the concrete, minimize outgassing, and promote adhesion.

Pigmented Basecoat: A colored basecoat of ResuShield MPE is applied, establishing the foundational color for the metallic effect.

Metallic Coat: The special metallic pigment is mixed with ResuShield UVE epoxy and applied, creating the unique, translucent stone-like pattern.

Protective Topcoat: Finally, a clear urethane topcoat (ResuShield HTS-100 or HPS-100) is rolled on, providing ultimate UV stability, chemical resistance, and the desired finish (satin or gloss).

Perguntas frequentes (FAQ)

Q: How does ResuShield™ Metallic II compare to epoxy flake or standard painted floors?

A: It is far more durable and visually unique than paint. Compared to flake systems, it offers a more sophisticated, seamless aesthetic with similar or better chemical and mechanical performance, and is easier to keep clean.

Q: What is the typical cost per square foot for this system?

A: The total cost varies based on concrete condition, project size, and geographic location. It is a premium system that offers long-term value through reduced maintenance and replacement costs. Contact us for a detailed quote specific to your project.

Q: Can it be installed as a DIY project?

A: No. Due to the precise mixing ratios, critical application windows (pot life), and need for professional surface preparation, installation must be performed by trained and approved contractors to ensure warranty validity and optimal performance.

Q: How long does the installation take, and when can I use the floor?

A: Depending on size, installation can take several days. The floor can typically accept light traffic after 24 hours of topcoat application at 75°F, but full cure and chemical resistance develop over 14 days.

Q: Is this system slip-resistant?

A: The standard topcoat provides a degree of slip resistance suitable for most commercial areas. For environments like commercial kitchens, bathrooms, or pool decks, specific aggregates can be incorporated into the topcoat to achieve higher slip ratings (e.g., R9-R11).

KAIDA PAINT Brand

KAIDA PAINT is a leading innovator in high-performance industrial and commercial coatings. We understand that your floor is a critical asset, requiring a balance of relentless durability and impressive aesthetics. Our ResuShield™ product line, including the Topcoat Metallic II system, is developed through rigorous R&D and real-world testing to solve the toughest flooring challenges. We partner directly with professional contractors and facility managers, providing not just premium products, but also comprehensive technical support, specification assistance, and reliability you can count on. Don’t settle for a floor that just gets by; invest in a system that enhances your operations and image. Contact KAIDA PAINT today to discuss your project requirements and receive a tailored solution proposal.

Why Choose Our Solution?

We are more than just a manufacturer; we are your flooring partner. Our products are manufactured to the highest standards, and we support a network of professional installers. We provide comprehensive technical data sheets, SDS, and on-site specification support to ensure your flooring investment is protected for the long term.

Take the Next Step with KAIDA PAINT

At KAIDA PAINT, we specialize in advanced coating solutions for industrial and commercial challenges. As a trusted manufacturer and solution provider, we combine high-quality products like the ResuShield™ Topcoat Metallic II system with deep technical expertise. We support contractors and companies with specification guidance, ensuring the right system is selected for your unique resistance requirements and design vision. Let us help you transform your space with a floor that is as tough as it is beautiful.

Ready to see how the ResuShield™ system can work for your facility? Contact our expert team today for a consultation, technical specifications, and a referral to an approved contractor near you.