Descrição

Visão geral do produto

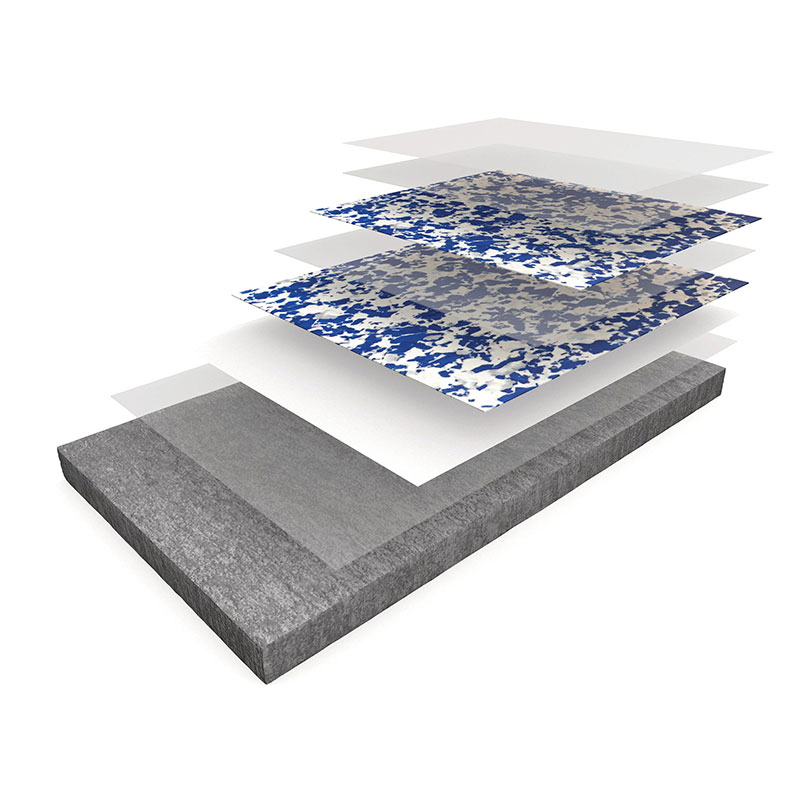

ResuShield™ DecoFlake II is a high-performance, decorative epoxy flooring system designed for demanding environments that require both durability and aesthetics. This seamless system combines 100% solids epoxy body coats with vibrant, color-fast vinyl chips, finished with a rugged urethane topcoat. It delivers exceptional resistance to wear, impact, and a wide range of chemicals, while providing a terrazzo-like appearance that is easy to clean and maintain. The ResuShield™ DecoFlake II system is the ideal solution for facilities prioritizing hygiene, safety, and long-term value, including warehouses, laboratories, hospitals, food processing plants, and retail spaces.

Common Industrial Flooring Problems & How ResuShield™ Solves Them

Industrial and commercial floors face constant abuse. Common issues include:

Cracking and Spalling: Heavy traffic and impact damage concrete. Our system’s flexible epoxy formulation resists cracking.

Dusting: Unsealed concrete creates dust, contaminating products and air. Our seamless coating permanently seals the surface.

Chemical Damage: Spills from oils, acids, and solvents degrade ordinary floors. ResuShield™ offers proven chemical resistance.

Wear and Tear: Forklifts and foot traffic quickly wear down surfaces. The system’s high abrasion resistance ensures long life.

Hygiene Concerns: Porous surfaces harbor bacteria and are difficult to sanitize. The non-porous, seamless finish allows for easy cleaning and meets stringent hygiene standards for industries like pharmaceuticals and food & beverage.

Slippery Surfaces: Wet or greasy floors pose safety risks. Textured finish options provide enhanced slip resistance.

ResuShield™ DecoFlake II: Core Features & Benefits

Unmatched Durability: Engineered to withstand heavy industrial traffic, impact, and abrasion. The system provides a nominal thickness of 60 mils for long-lasting protection.

Resistência química superior: The urethane topcoat shields against a broad spectrum of chemicals, including oils, greases, dilute acids, and alkalis, making it suitable for labs, garages, and manufacturing plants.

Sem costuras e higiénico: A monolithic surface eliminates grout lines and joints where dirt and germs can collect, facilitating easy cleaning and meeting FDA and USDA guidelines for cleanability.

Decorative Versatility: Available with Macro or Micro vinyl chips in unlimited standard and custom color blends to match any corporate or design aesthetic, enhancing the visual appeal of lobbies, showrooms, and workspaces.

Safety Enhanced: Can be formulated with anti-slip aggregates to achieve desired coefficient of friction ratings, promoting a safer environment even when wet.

Low VOC & Environmentally Considerate: Formulated to meet stringent indoor air quality standards, including California Section 01350, ensuring a healthier environment for occupants.

Especificações técnicas e dados de desempenho

The ResuShield™ DecoFlake II system is backed by rigorous testing to ensure consistent, reliable performance.

| Imóveis | Método de ensaio | Valor típico |

|---|---|---|

| Dureza | ASTM D-2240 (Shore D) | 75-80 |

| Resistência à tração | ASTM D-638 | 3.700 psi |

| Resistência à compressão | ASTM D-695 | 16.000 psi |

| Resistência à abrasão | ASTM D-4060 (CS-17 Wheel) | 4 mg loss (with grit) |

| Propagação da chama | ASTM E-84 | Classe A |

| Resistência da ligação ao betão | ASTM D-4541 | Substrate Failure (400+ psi) |

| Absorção de água | ASTM D-570 | 0.04% |

| Conteúdo de COV | – | 0 g/L (Topcoat) |

Aplicações ideais

This versatile flooring system is specified by companies and contractors across numerous sectors:

Industrial: Manufacturing plants, warehouses, automotive shops, repair facilities.

Comercial: Retail stores, supermarkets, showrooms, lobbies.

Institutional: Schools, universities, hospitals, government buildings.

Healthcare & Life Sciences: Hospitals, pharmaceutical cleanrooms, laboratories, veterinary clinics.

Alimentação e bebidas: Processing plants, kitchens, cafeterias, bottling facilities.

Sports & Recreation: Locker rooms, gyms, bathroom areas.

Professional Installation Process

A successful installation is key to performance. Our system is applied by certified professional installers following a precise multi-step process:

Preparação da superfície: Critical first step. Concrete is shot-blasted to a CSP 3-4 profile to ensure optimal adhesion. All cracks are filled.

Priming: A dedicated epoxy primer (e.g., ResuShield Glaze WB) is applied to seal and prepare the substrate.

Base/Broadcast Coats: The colored epoxy basecoat is applied, followed by an even broadcast of decorative chips.

Grout Coat: A clear epoxy coat is applied to seal the chips in place, creating a smooth, solid surface.

Urethane Topcoat: A high-performance polyurethane topcoat (e.g., ResuShield AT) is applied for ultimate chemical resistance, gloss retention, and durability.

Our technical support team provides specifications, on-site guidance, and quality control to ensure the system performs as designed.

Perguntas frequentes (FAQ)

What is the difference between epoxy and polyurethane topcoats?

Epoxy provides excellent adhesion and mechanical strength. The polyurethane topcoat on the ResuShield™ system adds superior UV stability, enhanced chemical resistance, and better flexibility, making the overall system more durable.

How long does the installation take?

Project timelines vary based on size, substrate condition, and environmental factors. Typically, for a standard area, the process from prep to final cure takes 3-5 days.

What is the maintenance required?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner is all that’s needed. No waxing or stripping is ever required.

Can this be installed over existing tile or coated floors?

In most cases, existing finishes must be completely removed to ensure proper adhesion to the concrete substrate. Our experts can assess your specific situation.

KAIDA PAINT Brand Introduction

KAIDA PAINT is a trusted leader in high-performance protective coatings and resinous flooring systems. We partner with facility managers, construction companies, and flooring contractors to solve complex challenges with innovative, reliable products like the ResuShield™ series. Our advantage lies in our dual role as both a quality manufacturer and a technical solutions partner. We provide comprehensive support, from initial specification and onsite troubleshooting to ensuring your flooring system delivers years of trouble-free service. Don’t just buy a coating—invest in a solution backed by expertise. Contact our technical sales team today for a project consultation, sample kit, or detailed quote.

Why Choose KAIDA PAINT for Your Flooring Project?

KAIDA PAINT is a leading manufacturer and solutions provider of high-performance industrial coatings. We don’t just sell products; we deliver comprehensive flooring solutions. Our team works directly with contractors, facility managers, and business owners to specify the correct system, provide detailed technical data, and support the application from start to finish. We combine high-quality materials with expert knowledge to ensure your flooring investment provides lasting value, safety, and aesthetics.

Get Your Custom Quote & Technical Specifications Today

Ready to upgrade your space with the durable, beautiful ResuShield™ DecoFlake II epoxy flooring system? Contact KAIDA PAINT today. Our specialists will provide you with a detailed price estimate, product samples, color pictures, and a full system specification tailored to your project’s needs. Let us help you find the best flooring solution for your industrial, commercial, or institutional facility.