Descrição

Visão geral do produto

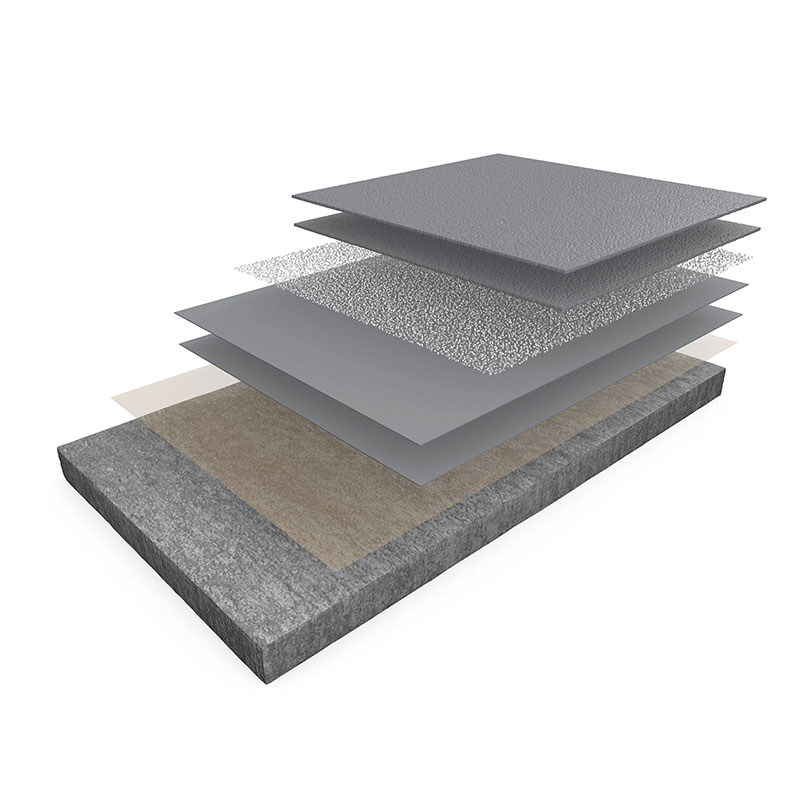

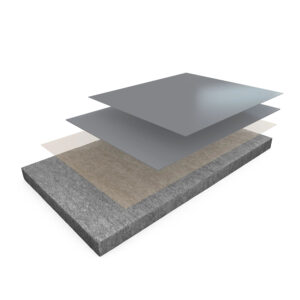

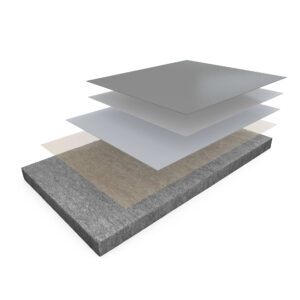

The ResdeckPro™ IV is an elastomeric, medium to heavy traffic urethane flooring system designed for new or existing concrete surfaces in need of waterproofing and repair. Comprising a primer, an elastomeric urethane basecoat, and two coats of an aromatic polyurea topcoat, it forms a seamless, four-layer protective system. It offers exceptional durability, outstanding thermal stability, and the ability to expand and contract with structural movement. The ResdeckPro™ IV coating provides a long-lasting solution for waterproofing, chemical resistance, and physical protection on interior and exterior decks, parking garages, walkways, and industrial facilities.

User Pain Points & Scenario Analysis

Industrial, commercial, and institutional flooring faces severe challenges impacting operational costs, safety, and aesthetics.

Concrete Degradation: Exposure to vehicle traffic, chemicals, and freeze-thaw cycles leads to cracking, spalling, and dusting of concrete and cement substrates.

Waterproofing Failure: Damaged waterproofing on parking decks, balconies, and roof decks causes leaks, damaging underlying structures and assets.

Safety Hazards: Slippery or uneven surfaces increase slip-and-fall risks; sharp objects or heavy equipment can gouge standard coatings.

Ataque químico: De-icing salts in garages, oils, and chemical spills in industrial areas corrode conventional flooring materials.

Difficult Maintenance: Standard floors are hard to clean; textured surfaces prohibit mopping, leading to poor hygiene and aged appearance.

Specific Application Needs:

Logistics Warehouses: Require high-wear, impact-resistant flooring that withstands frequent forklift traffic and heavy loads.

Parking Garages & Ramps: Need anti-slip, weather-resistant, and de-icing salt-proof coatings that endure constant vehicle braking and turning.

Fábricas de alimentos e bebidas: Demand seamless, easy-to-clean floors resistant to acids, alkalis, and frequent hot water washdowns.

Commercial Balconies & Walkways: Require aesthetic, waterproof, UV-stable coatings that accommodate thermal movement.

Product Solution & Detailed Features

The ResdeckPro™ IV urethane flooring system delivers a comprehensive solution to these challenges.

Superior Mechanical & Physical Properties

High Elasticity & Crack Bridging: The elastomeric system bridges substrate micro-cracks, resisting stress from thermal changes and structural movement.

Exceptional Abrasion & Impact Resistance: Engineered for medium to heavy traffic, it withstands continuous vehicular and pedestrian wear and accidental impacts.

Excelente aderência: A dedicated primer ensures a strong bond to various substrates including concrete, mortar, wood, and metal.

Custom Slip Resistance: Broadcast aggregate (silica sand) creates a safe, anti-slip surface (up to R9-R11 rating), even when wet.

Estabilidade térmica: Maintains performance across extreme temperatures without becoming brittle or overly soft.

Robust Chemical Resistance

The topcoat resists a wide range of common substances, including:

Automotive Fluids: Motor oil, gasoline, brake fluid.

De-icing Chemicals: Calcium chloride, rock salt.

Common Cleaners: Mild acids, alkalis, and detergents.

(Note: For unique chemical exposures, consult our Chemical Resistance Guide for a tailored solution.)

Aesthetics & Customization

Opções de cores: Available in Light Gray, Medium Gray, Dark Gray, Tan, and White. Custom colors are possible for large projects.

Finish & Texture: Provides a uniform, attractive finish. Texture is determined by the aggregate broadcast, ranging from fine to coarse for slip resistance.

Installation & Sustainability

Proven System: A clear, step-by-step installation process (primer, membrane, basecoat/broadcast, topcoat) ensures reliable performance.

Aplicação profissional: Designed for installation by trained and approved contractors to guarantee optimal results.

Low VOC Options: Formulations available with low VOC content, contributing to better indoor air quality during and after installation.

Technical Parameters & Authoritative Data

| Imóveis | Método de ensaio | ResdeckPro™ FLB (Basecoat) | ResdeckPro™ FLI (Topcoat) |

|---|---|---|---|

| Shore A Hardness | ASTM D2240 | 55 ± 5 | 85 ± 5 |

| Tear Resistance (Die C) | ASTM D624 | 250 ± 25 pli | 300 ± 50 pli |

| Resistência à tração | ASTM D412 | 800 ± 100 psi | 2500 ± 300 psi |

| Ultimate Elongation | ASTM D412 | 500 ± 50% | 500 ± 50% |

| VOC Content (Mixed) | ASTM D3960 | < 250 g/L | < 100 g/L |

| High Solids Content | ASTM C957 | Passar | Passar |

Requisitos do substrato: New concreto must be cured for a minimum of 28 days with a compressive strength of at least 3,000 psi. Surface profile must be CSP 3-4 (ICRI 310.2R) after abrasive blasting.

Áreas de aplicação

The ResdeckPro™ IV system is ideal for a multitude of demanding environments:

Parking Structures (Decks, Ramps, Drive Lanes)

Commercial & Institutional (Balconies, Terraces, Roof Decks, Walkways)

Instalações industriais (Manufacturing Plants, Loading Docks, Mezzanines)

Logística e armazenamento

Over Occupied Spaces (Waterproofing for areas with sensitive contents below)

Installation Process & Technical Support

A successful urethane floor coating project relies on precise installation.

Preparação da superfície: Critical step involving abrasive blasting to achieve CSP 3-4 profile, crack/joint repair, and thorough cleaning.

Aplicação do primário: Ensures optimal adhesion of the system to the prepared substrate.

Membrane & Basecoat: An elastomeric urethane basecoat is applied, often incorporating a reinforcing fabric for cracks. Aggregate is broadcast for texture and slip resistance.

Topcoat Application: One or two coats of high-performance aromatic polyurea topcoat are applied for protection and finish. A second topcoat is recommended for high-wear areas like ramps.

Curing & Traffic: Allow 24 hrs for light foot traffic, 72 hrs for heavy traffic/vehicles.

Our Support: KAIDA PAINT provides more than just products. We offer technical specification assistance, on-site project consultation, and access to a network of certified installers to ensure your flooring system performs as designed.

Perguntas frequentes (FAQ)

What is the difference between a urethane flooring system and an epoxy floor?

While both are resinous floorings, urethane systems like ResdeckPro™ IV typically offer superior flexibility, UV stability (with aliphatic topcoats), thermal cycle resistance, and abrasion resistance. Epoxy systems are generally harder and more rigid but can be prone to yellowing and chalking under UV exposure.

How long does it take to install the ResdeckPro™ IV system?

The timeline depends on area size, substrate condition, and weather. Typically, surface prep can take 1-2 days, with coating application over 2-3 days. Full cure for vehicle traffic is 72 hours minimum.

How do I maintain a urethane floor coating?

Regular sweeping and occasional cleaning with a mild detergent and a bristle brush or power scrubber are recommended. Avoid harsh solvents and metal shovels for ice removal. Inspect periodically for damage.

What is the minimum application temperature?

The substrate and ambient temperature should be between 50°F and 90°F (10°C – 32°C) during application.

Social Proof & Trust Building

Histórico comprovado: Specified for numerous commercial parking garages, institutional buildings, and industrial facilities across North America.

Manufacturer Backing: ResdeckPro™ IV is developed by KAIDA PAINT, a leader in high performance industrial coatings with rigorous quality control.

Expert Network: Available through a dedicated network of experienced flooring contractors and companies.

Partner with KAIDA PAINT

Looking for a flooring partner you can trust? KAIDA PAINT isn’t just another supplier of industrial paint and coatings. We are solution architects for your most challenging flooring problems. With decades of expertise in urethane and polyurethane resin technology, we develop products like the ResdeckPro™ IV system that are engineered to perform under real-world stress. Our difference lies in our end-to-end support: from helping you specify the right system based on your exact traffic, chemical, and aesthetic needs, to connecting you with our network of vetted application contractors. We stand behind our products with robust technical data and a commitment to quality, ensuring your investment in a KAIDA PAINT flooring solution delivers long-term value, safety, and performance. Contact our team today to discuss your project requirements.

At KAIDA PAINT, we specialize in formulating and delivering advanced urethane and polyurethane coating solutions for the most demanding industrial and commercial environments. As both a manufacturer and a technical partner, we provide:

World-class product expertise em urethane flooring systems.

Unparalleled technical and specification support from project conception to completion.

Direct access to a dedicated commercial team focused on your project’s success.

Ready to specify or install the ultimate waterproofing and wear-resistant flooring system? Contact our High-Performance Flooring experts today for a consultation, detailed technical data sheets, or to find a qualified installer near you.