Descrição

Visão geral do produto

Polypro™ NMP Performance EV is a state-of-the-art, fast-cure polyurethane flooring system engineered to deliver superior durability, chemical resistance, and safety in high-traffic industrial settings. This advanced system combines a robust polyurethane matrix with a high-performance topcoat, creating a seamless, monolithic surface that protects concrete substrates from abrasion, impact, and aggressive chemical exposure. Ideal for facilities requiring a fast return-to-service, such as manufacturing plants, warehouses, food processing areas, and automotive shops, Polypro™ NMP Performance EV offers a reliable, long-lasting flooring solution that minimizes downtime and maximizes productivity.

Why Industrial Flooring Fails: Common Pain Points We Solve

Industrial and commercial floors face relentless stress. Traditional concrete surfaces, standard epoxy coatings, or inadequate paint solutions often lead to:

Cracking and Degradation: Untreated cement and mortar substrates are prone to cracking under thermal movement or heavy loads.

Dusting and Erosion: Constant traffic wears down surfaces, creating dust that contaminates products and equipment.

Chemical Attack: Spills of oils, solvents, acids, and cleaning agents can quickly degrade standard floor finishes.

Slippery Surfaces: Wet or greasy conditions pose significant safety hazards without proper anti slip technology.

Difficult Maintenance: Porous or damaged floors are hard to clean, increasing sanitation costs and downtime.

Lengthy Installation & Curing: Traditional systems require long cure times, disrupting operations for days or weeks.

For contractors and facility managers, these issues translate into high maintenance cost, safety liabilities, and operational inefficiency. The right flooring system is not a commodity—it’s a critical operational asset.

Polypro™ NMP Performance EV: Engineered for Performance

Our polyurethane coating is more than just a sealer; it’s a complete protective system. Here’s how it solves your flooring challenges:

1. Unmatched Durability & Mechanical Strength:

Extreme Abrasion Resistance: Withstands heavy wheeled traffic and constant footfall, significantly outperforming standard epoxy and other urethane finishes. This extends the floor’s lifecycle, reducing long-term cost.

High Impact Resistance: The flexible polyurethane resin matrix absorbs shocks from dropped tools and equipment without cracking.

Sem costuras e higiénico: The monolithic finish eliminates joints and pores where dirt and bacteria can hide, making it easy to clean and ideal for industrial hygiene standards.

2. Superior Chemical & Stain Resistance:

Specifically formulated to resist a broad spectrum of chemicals, including oils, greases, dilute acids, alkalis, and solvents commonly found in industrial settings.

The non-porous surface prevents absorption, allowing for easy spill cleanup and preventing permanent staining.

3. Enhanced Safety with Anti-Slip Properties:

Available with integrated aggregate or textured topcoat options to provide a high anti slip polyurethane surface, even when wet. This meets or exceeds safety standards (e.g., DIN 51130) for urethane floor coating in workplaces.

4. Fast Installation & Rapid Return to Service:

Fast-Cure Formulation: The system allows for quick installation and remarkably fast curing times. In many cases, light foot traffic can resume in just 7-12 hours, and full service in 24-48 hours, minimizing operational disruption.

Application Flexibility: Can be applied over properly prepared concrete, epoxy, and other substrates by certified installers.

5. Aesthetic Versatility & Long-Term Value:

Available in a range of colors and finishes (gloss, semi-gloss, satin) to meet aesthetic and functional lighting requirements.

The combination of longevity, low maintenance, and durability delivers an excellent return on investment, lowering the total cost of ownership.

Especificações técnicas e dados de desempenho

| Imóveis | Método de ensaio | Result / Performance Data |

|---|---|---|

| Tipo de sistema | – | Poliuretano Resin with Urethane Topcoat |

| Typical Total Thickness | – | 40 – 80 mils (1.0 – 2.0 mm) |

| Adhesion to Concrete | ASTM D723 | > 350 psi (Exceeds standard requirements) |

| Resistência à abrasão | ASTM D4060 (CS-17 Wheel) | Excellent (Low weight loss) |

| Resistência química | ASTM D1308 | Resistant to many acids, alkalis, solvents, oils |

| Resistência ao deslizamento (húmido) | DIN 51130 / ASTM E303 | Rating available (e.g., R9-R10 for moderate to high slip resistance) |

| Resistência à compressão | ASTM D695 | Muito elevado |

| Resistência à flexão | ASTM D790 | High (Indicates flexibility) |

| Conteúdo de COV | EPA Method 24 | Low-VOC formula available |

Data is representative; specific values depend on system configuration and substrate. Contact us for a detailed datasheet.

Ideal Application Areas

Polypro™ NMP Performance EV is the solution for companies across diverse sectors:

Manufacturing & Warehousing: For aisles, production areas, and loading docks requiring extreme durability.

Processamento de alimentos e bebidas: Where chemical resistance, easy cleaning, and USDA/FDA compliance are critical.

Setor automóvel e aeroespacial: Resistant to fuels, hydraulic fluids, and tire marks in repair bays and hangars.

Pharmaceutical & Laboratories: Provides seamless, cleanable surfaces that meet cGMP standards.

Commercial Kitchens & Breweries: Handles thermal shock, steam cleaning, and frequent chemical cleaning.

Parking Garages & Logistics Centers: Offers excellent abrasion resistance and a long-lasting finish.

Professional Installation Process

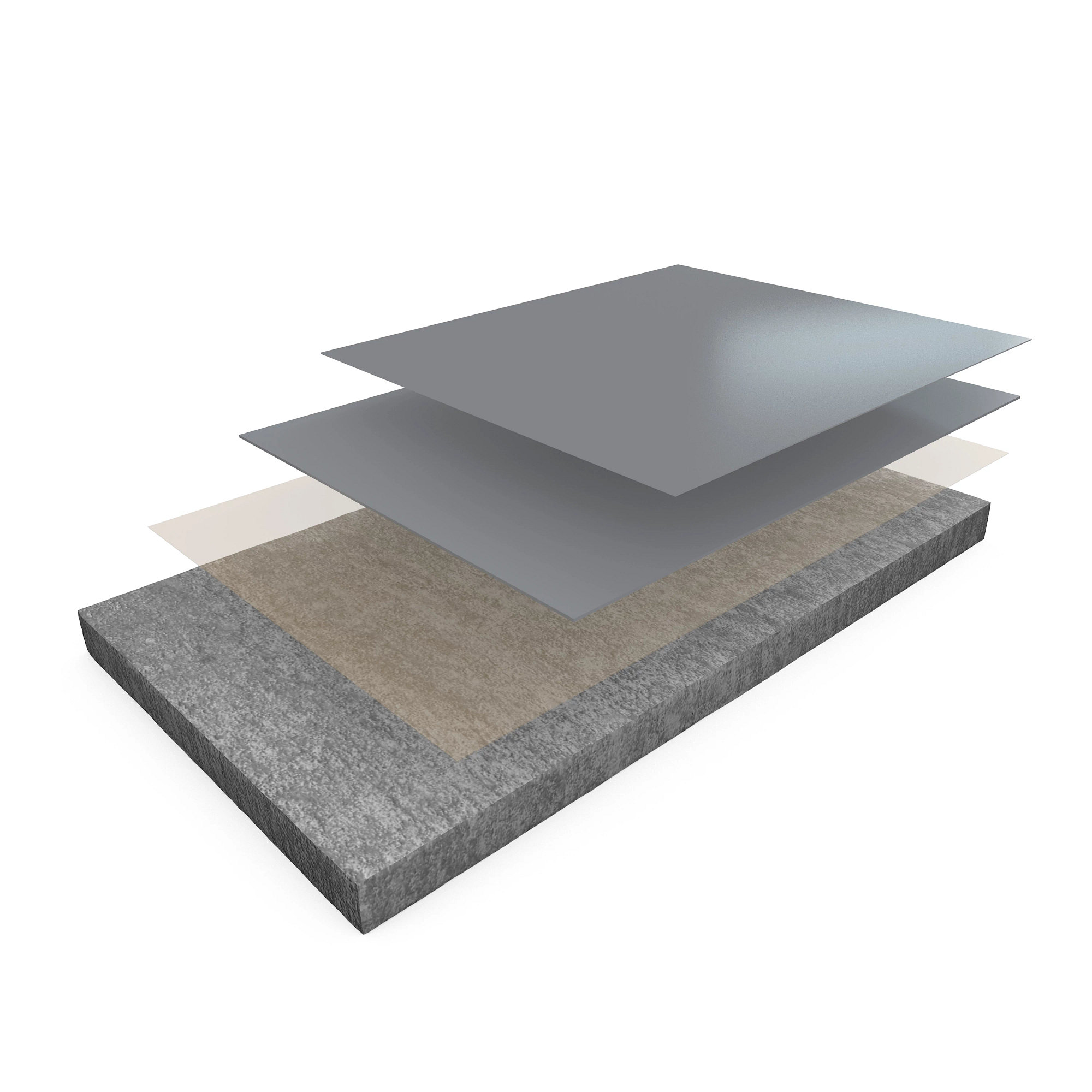

Optimal performance depends on correct installation. Our process, executed by qualified contractors, ensures a flawless result:

Surface Assessment & Preparation: Our experts evaluate the concrete substrate for moisture, cracks, and strength. Proper mechanical preparation (e.g., shot blasting) is crucial.

Primer/Basecoat Application: A primer or basecoat is applied to ensure perfect adhesion and seal the substrate.

Mid-Build Layer (If Required): For added thickness or floor leveling, a polyurethane mortar or self-leveling layer is applied.

Aplicação do revestimento superior: The high-performance urethane topcoat is applied, often with anti-slip additives, to create the final wear and chemical-resistant surface.

Curing & Commissioning: The area is protected during the short cure period before being released for full service.

We provide full technical support, from specification and installation guidance to on-site consultation, ensuring your project’s success.

Perguntas frequentes (FAQ)

What is the difference between Polyurethane and Epoxy Flooring?

Answer: While both are resinous flooring products, polyurethane systems generally offer superior flexibility, abrasion resistance, UV stability, and resistance to a wider range of chemicals. Epoxy can be more brittle and may yellow or chalk under UV exposure. Polyurethane is often the preferred topcoat over epoxy for enhanced performance.

How long does it take to install Polypro™ NMP Performance EV?

Answer: Depending on the area size and system thickness, installation can often be completed in 2-4 days. Its fast-cure properties mean the floor can typically handle light traffic within hours and full operational loads within 24-48 hours.

How do I maintain a polyurethane industrial floor?

Answer: Maintenance is straightforward. Sweep or dust mop regularly. Clean with neutral pH cleaners and a soft mop or auto-scrubber. Avoid harsh acids or abrasive pads. Promptly clean up chemical spills. This routine will significantly extend the life of your floor finish.

What is the minimum temperature for installation?

Answer: Optimal application occurs with substrate and ambient temperatures between 50°F (10°C) and 90°F (32°C). Specific conditions should be confirmed with the product data sheet and our technical team.

Trust Built on Proven Results

We have successfully implemented our urethane flooring systems for leading companies in manufacturing, logistics, and food production. Our products are backed by rigorous testing and are specified by engineers and facility managers who demand reliability.

Certified Quality: Our formulations meet stringent industrial and environmental standards.

Expert Network: We work with a nationwide network of certified and experienced installer contractors.

Dedicated Support: From initial inquiry to post-installation follow-up, our team is here to ensure your satisfaction.

KAIDA PAINT: Your Partner in High-Performance Industrial Flooring

KAIDA PAINT stands at the forefront of high-performance protective coatings. For decades, we have dedicated ourselves to formulating and delivering advanced urethane and epoxy flooring systems that solve real-world challenges in industrial, commercial, and institutional settings. Our products, like the Polypro™ NMP Performance EV, are born from extensive R&D and a deep understanding of substrate science, chemical resistance, and mechanical stress.

What sets KAIDA PAINT apart is our holistic approach. We are not just a supplier; we are your technical partner. Our team of experts works closely with facility managers, specifiers, and contractors to develop tailored solutions that balance performance, cost, and project timelines. From initial site assessment and system design to installation support and maintenance guidance, we are with you every step of the way. We invest in the certification and training of our applicator network to ensure every project meets our exacting standards.

If you are evaluating flooring options for a new build, a retrofit, or a maintenance overhaul, partner with a company that brings both premium products and proven expertise. Contact KAIDA PAINT today to schedule a technical consultation. Let us show you how our Polypro™ systems can provide a stronger foundation for your operations.