الوصف

نظرة عامة على المنتج

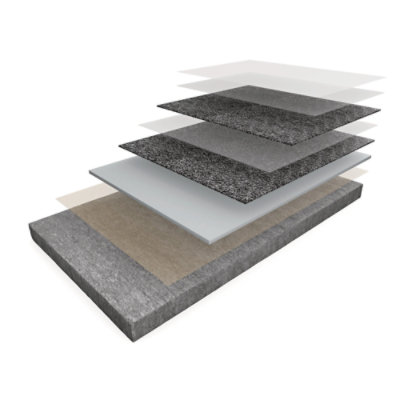

Ure-Crete™ MDQ is a high-performance, decorative cementitious urethane flooring system designed for industrial and commercial spaces that demand a perfect balance of extreme durability, chemical resistance, and aesthetic appeal. This advanced urethane concrete solution combines a cementitious matrix with polyurethane resins and a colored quartz broadcast, creating a seamless, monolithic surface. It offers exceptional resistance to abrasion, impact, and a wide range of chemicals, while its textured, non-slip finish promotes safety. As a 100% solids, low-VOC system, Ure-Crete™ MDQ provides a robust, long-lasting coating that is ideal for installation in manufacturing facilities, warehouses, and high-traffic areas where a durable, easy-to-clean flooring solution is paramount. Choosing the right products from reputable companies ensures a high-quality outcome for both contractors and end-users, managing the overall project cost effectively.

User Pain Points & Scenario Analysis

Industrial and commercial floors face relentless challenges that standard concrete or epoxy paint cannot withstand for long. Common issues include:

Dusting and Degradation: Untreated or poorly coated concrete slabs generate dust, contaminating products and air quality.

Cracking and Spalling: Heavy loads and thermal cycling cause cracks, leading to costly repairs and downtime.

Chemical Attack: Spills of oils, acids, solvents, and cleaning agents can rapidly degrade standard floor coatings.

Abrasion and Impact Damage: Constant forklift traffic, dropped tools, and heavy machinery wear down floors, creating unsightly and unsafe surfaces.

النظافة وقابلية التنظيف: Porous surfaces harbor bacteria and are difficult to sanitize, a critical concern in food & beverage or pharmaceutical settings.

Slippery Surfaces: Wet or oily conditions create hazardous environments for personnel.

Specific Scenario Needs:

Food & Beverage Plants: Require floors that are impervious to acidic juices, fats, and aggressive sanitizers, with a seamless, easy-clean finish.

Logistics & Warehousing: Need a system that can withstand extreme impact from pallet drops and constant abrasion from wheeled traffic.

Automotive & Machine Shops: Demand resistance to oils, fuels, and hydraulic fluids, combined with high durability.

Commercial Kitchens & Parking Garages: Benefit from a slip-resistant texture and a surface that can handle thermal shock and de-icing salts.

Product Solution & Key Features

Ure-Crete™ MDQ directly addresses these pain points with a urethane mortar system that outperforms conventional options.

متانة لا مثيل لها: This cementitious urethane system forms a tenacious bond with the substrate, offering exceptional compressive and tensile strength. It resists heavy point loads and impact without cracking.

مقاومة فائقة للمواد الكيميائية: The polyurethane top layer provides excellent resistance to a wide spectrum of chemicals, including oils, greases, dilute acids, alkalis, and many solvents, protecting your concrete substrate.

Abrasion & Wear Resistance: The dense, quartz-reinforced surface offers outstanding resistance to scuffing and abrasion from foot and wheeled traffic, ensuring long-term performance and appearance.

سلس وصحي: The fluid-applied system creates a joint-free surface with no grout lines or cracks to trap dirt, moisture, or bacteria, making it ideal for environments where cleanliness is critical.

Safety-First Design: Available with integral aggregates or a textured finish, the floor achieves high static and dynamic coefficient of friction (COF) ratings, providing a reliable non-slip surface even when wet.

Decorative Versatility: Available in a wide range of standard and custom quartz colors, allowing for aesthetic zoning, branding, or creating a bright, clean-looking environment. It provides a uniform, attractive finish.

Thermal & Moisture Stability: Performs reliably across a broad temperature range and demonstrates low moisture vapor transmission, reducing the risk of blistering or delamination.

المواصفات والبيانات الفنية

The performance of Ure-Crete™ MDQ is verified by standardized testing, providing contractors and specifiers with confidence.

| الممتلكات | طريقة الاختبار | Typical Value | Benefit |

|---|---|---|---|

| System Thickness | Nominal Application | 3/16″ to 1/4″ | Robust, wear-resistant profile |

| قوة الانضغاط | ASTM C-579 | >12,500 psi | Withstands extreme loads |

| قوة الشد | ASTM D-638 | >4,000 psi | High cohesion & crack resistance |

| Adhesion to Concrete | ASTM D-4541 | >400 psi (substrate fails) | Superior bonding, no delamination |

| مقاومة التآكل | CS-17 Wheel, 1000g Load, 1000 Cycles (ASTM D-4060) | Minimal mass loss (<10 mg) | Extremely long service life |

| الصلابة | Shore D (ASTM D-2240) | 75-80 | Surface resists cutting and gouging |

| التعرض للمواد الكيميائية | Immersion Testing | Resists oils, fats, dilute acids, alkalis | Protects against common spills |

| محتوى المركبات العضوية المتطايرة | Calculated | 0 g/L | Compliant with strict indoor air quality standards |

مجالات التطبيق

Ure-Crete™ MDQ is the solution of choice for diverse demanding environments:

Manufacturing & Industrial Plants

Food & Beverage Processing & Packaging

Automotive & Aerospace Facilities

Pharmaceutical & Life Sciences

Warehouses & Distribution Centers

Commercial Kitchens & Cafeterias

Parking Garages & Service Bays

Laboratories & Technical Schools

Installation Process & Technical Support

Professional installation by qualified contractors is key to achieving the system’s full potential. The key steps include:

تحضير السطح: Critical first step. The concrete substrate must be clean, dry, sound, and profiled via shot blasting to CSP 3-5.

Priming: A moisture-tolerant primer may be applied on porous substrates to ensure optimal adhesion.

Basecoat/Mortar Application: The multi-component cementitious urethane mortar is mixed and applied via pin rake or trowel at the specified thickness.

Aggregate Broadcast: Colored quartz is broadcast into the wet coating for texture, color, and durability.

Sealing & Topcoating: After curing and removal of excess aggregate, a high-performance polyurethane sealer or topcoat is applied to lock in the quartz and provide enhanced chemical and abrasion resistance.

Curing: The floor requires a defined cure time before light traffic and full service.

Our Support: We provide comprehensive technical data sheets, pictures of procedures, on-site consultation, and specification guidance to ensure your flooring project is a success from design to completion.

الأسئلة الشائعة (FAQ)

Q1: What is the main difference between a cementitious urethane system and an epoxy floor?

A: While both are durable, cementitious urethane systems like Ure-Crete™ MDQ offer superior flexibility (elasticity), better resistance to thermal shock, and enhanced UV stability compared to typical epoxy coatings. This makes urethanes less prone to cracking and yellowing, ideal for environments with temperature fluctuations or partial UV exposure.

Q2: How long does the installation process take?

A: For a typical 10,000 sq. ft. area, the active installation phase can take 3-5 days, depending on conditions and system complexity. Full cure for heavy traffic may require up to 5-7 days. We provide detailed project timelines.

Q3: What is the typical cost range for a cementitious urethane floor?

A: The cost varies based on substrate condition, system thickness, project size, and geographic location. Ure-Crete™ MDQ is a premium, long-life system. Contact us for a detailed quote that considers your specific requirements and delivers true lifecycle value.

Q4: How do I maintain this type of flooring?

A: Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are usually sufficient. Avoid harsh abrasive cleaners or steel wool. The seamless surface makes deep cleaning fast and effective.

Why Choose Our Solution?

We are a leading provider of high-performance industrial flooring solutions. Our products, like Ure-Crete™ MDQ, are specified by Fortune 500 companies and trusted by professional contractors nationwide. We back our systems with:

أداء مثبت: Technical data derived from independent ASTM testing.

Expert Specification Support: Assistance in selecting the right system for your chemical and physical challenges.

Quality Assurance: Consistent, high-quality products manufactured under strict controls.

KAIDA PAINT Brand

KAIDA PAINT is a leading innovator in the field of high-performance protective coatings and flooring systems. We specialize in formulating and manufacturing advanced solutions, like the Ure-Crete™ MD cementitious urethane system, that are engineered to solve the most demanding challenges in industrial and commercial environments. Our difference lies in our collaborative approach. We work directly with facility managers, specifiers, and contractors, providing not just premium products, but also the technical expertise, specification support, and on-site guidance needed to ensure flawless installation and long-term performance. We are committed to delivering solutions that optimize lifecycle cost, enhance safety, and withstand the test of time. For a solution tailored to your specific facility needs, consult with a KAIDA PAINT expert today.

Ready to transform your floor? Contact our technical specialists today for a free project evaluation, specification review, or to request material samples and pictures of completed projects. Let us help you specify the right system for your demanding application.