الوصف

نظرة عامة على المنتج

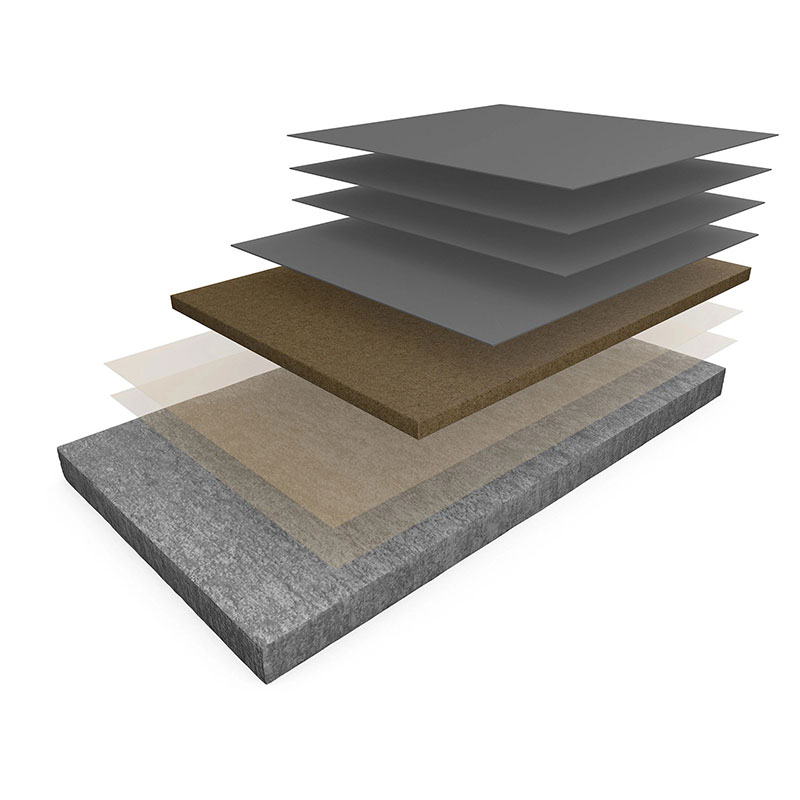

The ResuShield™ Screed TG46 Advanced NMP Performance EV is a heavy-duty, nominal 1/8-inch to 1/4-inch thick epoxy mortar resurfacing system designed to extend the life of concrete floors in the most demanding industrial environments. Comprising a multi-layer system including a moisture vapor barrier, primer, epoxy/aggregate mortar, grout, build coat, and topcoats, it provides a seamless, monolithic, and highly protective topping. It delivers exceptional resistance to N-Methyl-2-pyrrolidone (NMP) exposure, high compressive strength, superior slip resistance, and fast cure times. This system is the ideal solution for refurbishing worn concrete or protecting new substrates in facilities such as EV battery manufacturing plants, areas with heavy AGV traffic, and drum storage rooms.

User Pain Points & Scenario Analysis

Industrial and commercial concrete floors face constant degradation. Common problems include cracking, dusting, chemical corrosion from spills, severe mechanical wear from heavy loads and traffic, moisture vapor transmission causing coating failure, and difficulties in maintaining cleanliness and sanitation. Specific scenarios highlight these needs:

EV & Battery Manufacturing: Floors require extended resistance to aggressive solvents like NMP used in electrode production, combined with the ability to withstand heavy Automated Guided Vehicle (AGV) traffic and allow for thorough carbon black cleanup.

Logistics & Warehousing: Floors must endure extreme impact from dropped goods, constant abrasion from forklifts and pallet jacks, and support heavy static loads without cracking.

Food & Beverage Processing: Surfaces need to be seamless, impervious, chemically resistant to cleaning agents and spills, and easy to clean and sanitize to meet strict hygiene standards.

General Industrial Facilities: Companies and contractors seek a durable, long-lasting flooring solution that reduces long-term cost, minimizes downtime for repair, and provides a safe, slip-resistant surface.

Product Solution & Key Features

The ResuShield TG46 system is engineered to directly address these challenges with a comprehensive coating solution.

Unmatched Chemical Resistance: Specifically formulated for industrial settings with NMP exposure, demonstrating resistance for up to 14 days when tested to ASTM D1308. The topcoat provides broad chemical resistance to oils, greases, and many common industrial chemicals.

Superior Mechanical Durability: An epoxy mortar system with added compressive strength up to 15,000 PSI protects against heavy impact and wear. It withstands AGV traffic, heavy loads, and repetitive forklift use, making it an excellent alternative to stainless steel floors.

Enhanced Safety & Cleanability: Features a dynamic slip coefficient of .72 (vs. the .42 industry standard per ANSI A326.3), providing a safer slip-resistant surface. The seamless finish allows for thorough and easy cleaning, even of fine particles like carbon black.

Moisture Tolerance & Fast Application: The integrated Moisture Vapor Barrier (MVB) coating manages substrate moisture, allowing application to green concrete (reducing cure time from 28 days to 7 days). This speeds up project timelines for contractors and companies.

Customizable Aesthetics: Available in standard and unlimited custom colors. Whether you need a bright white for clean rooms, a classic gray, or specific brand colors, the system can be tailored to your facility’s design and ideas.

High-Performance Specifications: Abrasion resistance (ASTM D4060) is 4-6 times greater than standard epoxy topcoats, ensuring a long-lasting finish.

Technical Parameters & Data

| المعلمة | Specification / Performance Data | طريقة الاختبار |

|---|---|---|

| System Thickness | Nominal 1/8″ to 1/4″ (3-6 mm) | – |

| قوة الانضغاط | Up to 15,000 psi | – |

| NMP Chemical Resistance | Up to 14 days exposure | ASTM D1308 |

| Slip Resistance (Wet) | Dynamic Coefficient of Friction (DCOF) ≥ 0.72 | ANSI A326.3 |

| مقاومة التآكل | High (4-6x standard epoxy) | ASTM D4060 |

| محتوى المركبات العضوية المتطايرة | Low-VOC formulations (<100 g/L) | – |

| Application Temperature | 50°F – 90°F (10°C – 32°C) | – |

| Traffic Ready (Light) | ~24 hours (varies with conditions) | – |

مجالات التطبيق

This versatile industrial flooring system is specified by companies and contractors for numerous demanding environments:

Electric Vehicle (EV) & Battery Manufacturing Plants

Industrial Warehouses & Logistics Centers (high AGV/forklift traffic)

Pharmaceutical & Chemical Processing Areas

Food & Beverage Production and Pack Processing Areas

Automotive Manufacturing & Assembly Facilities

Aircraft Hangars & Maintenance Bays

Loading Docks & Drum Storage Rooms

Installation Process & Technical Support

Professional installation by approved contractors is crucial for optimal performance. The key steps include:

تحضير السطح: Concrete must be abrasive blasted to a CSP 4-6 profile, cleaned, and repaired. Proper prep is critical for adhesion.

Moisture Vapor Barrier (MVB) Coat: Applied to mitigate moisture issues from the concrete slab.

التمهيدي: Enhances bond between the MVB and the mortar.

Mortar Application: The epoxy/aggregate mortar is screeded and troweled to the desired thickness to level and resurface the floor.

Grout & Build Coats: Fill the mortar surface and build the final profile.

تطبيق الطلاء العلوي: The final NMP- and slip-resistant polyurethane or epoxy topcoat is applied for maximum chemical protection and finish.

We provide unparalleled technical and specification service, from pre-application consultation to on-site support, ensuring your flooring system is designed and installed to perform.

الأسئلة الشائعة (FAQ)

What makes the ResuShield TG46 system suitable for EV battery plants?

Its key advantage is exceptional resistance to N-Methyl-2-pyrrolidone (NMP), a solvent commonly used in electrode manufacturing, for up to 14 days. Combined with high strength, AGV traffic tolerance, and easy cleanability, it is the preferred flooring solution for cathode operating environments.

Can this epoxy flooring be applied to new concrete?

Yes. The system includes a moisture vapor barrier that allows application to green concrete, significantly reducing the required substrate cure time from 28 days down to just 7 days, accelerating project schedules.

How do I maintain an industrial troweled mortar floor?

Daily dust mopping and prompt spill cleanup are essential. Periodic damp mopping with a mild detergent is recommended. For slip-resistant textures, scrubbing with a bristle brush may be necessary. Avoid harsh cleaners and always test in a small area first.

What is the typical cost per square foot for this system?

The total installed cost varies based on substrate condition, project size, location, and chosen specifications. It is a premium, heavy-duty system designed for long-term value and reduced lifecycle cost. Contact us for a detailed quote tailored to your specific project.

Proof & Trust Building

Our products and solutions are trusted by leading manufacturers and contractors worldwide. The ResuShield TG46 system is developed based on rigorous testing and is backed by KAIDA PAINT’ world-class technical expertise. We support projects of all scales, from large commercial and industrial warehouses to specialized manufacturing facilities.

Kaida Paint Brand Introduction:

Kaida Paint is a leading manufacturer and solution provider of high-performance industrial and commercial coatings. We specialize in developing advanced, durable flooring systems like the ResuShield™ line to solve the toughest challenges faced by facilities worldwide. Our difference lies in our dual role: we produce premium, reliable products and back them with expert technical support and specification services for contractors and end-user companies. We partner with you from concept to completion, ensuring your flooring installation delivers maximum longevity, safety, and value. Choose Kaida Paint for a professional partnership and the best industrial flooring solutions. Contact our team today to start your project.

Partner with Kaida Paint

At Kaida Paint, we are more than just a paint and coating manufacturer; we are your dedicated partner for high-performance industrial flooring solutions. We combine advanced products like the ResuShield TG46 with deep application expertise and full-project support for contractors and companies. Whether you’re planning a new facility, a repair, or a full resurfacing project, our team is here to ensure you get the best system for your needs, price, and timeline.

Ready to upgrade your floor to withstand the toughest challenges? Contact Kaida Paint today for a technical consultation, a detailed quote, or to discuss your specific project requirements. Let us provide the durable, safe, and high-performance flooring solution your business deserves.