الوصف

نظرة عامة على المنتج

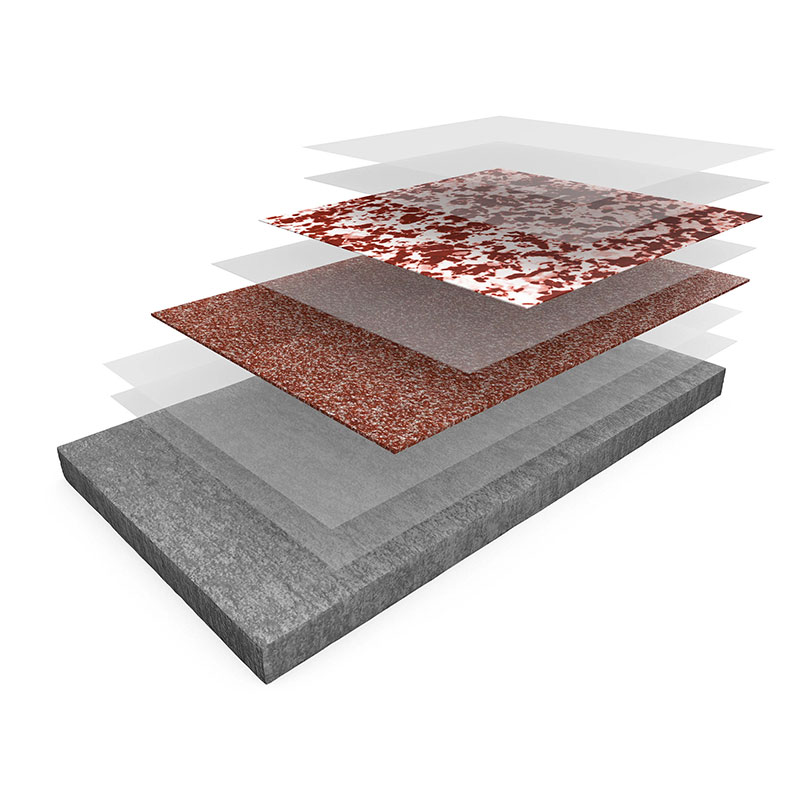

ResuShield™ Deco Flake DQF is a high-performance, multi-layer epoxy flooring system designed for demanding commercial and industrial environments. By combining two distinct layers of decorative broadcast media—colored quartz and decorative vinyl flake—with durable, UV-resistant epoxy resins, it creates a seamless, sanitary, and uniquely attractive mosaic finish. This system offers exceptional mechanical strength, chemical resistance, and limitless aesthetic customization, providing a long-lasting and easy-to-maintain flooring solution for facilities where durability, safety, and appearance are critical.

Common Industrial Flooring Problems & How ResuShield™ Solves Them

Choosing the wrong flooring can lead to costly downtime, safety hazards, and premature failure. Here are the common pain points companies and contractors face:

Cracking & Spalling: Standard concrete floors are prone to damage from heavy loads and impact.

ResuShield™ Solution: The multi-layer epoxy system provides superior tensile strength and flexibility, bridging minor substrate cracks and resisting impact damage.

Dusting & Degradation: Untreated or poorly coated floors generate dust, contaminating products and air quality.

ResuShield™ Solution: A seamless, non-porous coating seals the concrete completely, eliminating dust and providing a smooth, easy-to-clean surface.

Chemical & Stain Damage: Facilities like labs, food & beverage plants, and warehouses are exposed to oils, acids, solvents, and other corrosive substances.

ResuShield™ Solution: The chemical-resistant topcoat provides a protective barrier against a wide range of chemicals, ensuring easy cleanup and long-term integrity.

Slippery, Unsafe Surfaces: Wet or greasy floors pose significant slip-and-fall risks.

ResuShield™ Solution: The broadcast quartz and flake aggregates, sealed within the system, create a textured surface that enhances traction and slip resistance, even when wet.

Dull & Uninspiring Aesthetics: Industrial spaces often lack visual appeal, which can impact morale and brand perception.

ResuShield™ Solution: With a vast array of flake colors and quartz blends, the system offers limitless design possibilities—from subtle grey tones to vibrant custom patterns—creating a professional and attractive finish.

ResuShield™ Deco Flake DQF: Core Features & Technical Advantages

This epoxy flooring system is engineered to perform. Below are its key characteristics and verified performance data.

Unmatched Durability & Physical Properties

The ResuShield™ DQF system is built to withstand the toughest conditions.

Abrasion Resistance: With a Taber Abrasion loss of only 18 mg (ASTM D4060), it significantly outlasts standard epoxy floors, ideal for high-traffic areas.

High Load-Bearing Strength: Compressive strength exceeds 13,500 psi (ASTM D695), capable of supporting heavy pallet racks, forklift traffic, and industrial equipment.

Superior Adhesion: The epoxy bonds tenaciously to the concrete substrate, with adhesion strength (ASTM D7234) so high that failure typically occurs within the concrete itself, not at the bond line.

سلس وصحي: The monolithic coating eliminates joints and cracks where bacteria and dirt can accumulate, making it perfect for clean rooms, pharmaceutical facilities, and food processing plants.

Proven Chemical & Stain Resistance

The topcoat is formulated to resist a broad spectrum of industrial chemicals, facilitating easy cleaning and maintenance. Refer to the official Chemical Resistance Guide for specific compatibilities.

Safety & Aesthetic Flexibility

Enhanced Slip Resistance: The textured surface from the quartz and flake broadcast provides a wet static coefficient of friction (SCOF) that meets safety standards for many environments.

Custom Visual Appeal: Choose from standard or custom blends of colored quartz and decorative flake (in 1/4″, 1/8″, or micro sizes) to match any corporate color scheme or design vision. A high-gloss, UV-stable finish retains its color and shine for years.

LEED® Contribution: The low-VOC formulation can contribute to points under the LEED v4 rating system for building projects focused on environmental responsibility.

Technical Specifications at a Glance

| الممتلكات | طريقة الاختبار | بيانات الأداء |

|---|---|---|

| مقاومة التآكل | ASTM D4060 | 18 mg loss |

| Adhesion to Concrete | ASTM D7234 | 732 psi (Concrete Failure) |

| قوة الانضغاط | ASTM D695 | 13,500 psi |

| قوة الشد | ASTM D2370 | 8,000 psi |

| الصلابة (Shore D) | ASTM D2240 | 80-85 |

| VOC Content (Mixed) | ASTM D3960 | < 50 g/L |

Application Areas: Where ResuShield™ DQF Excels

This versatile system is the best solution for a wide range of sectors:

Healthcare & Senior Living: Nursing homes, hospitals, and clinics benefit from its sanitary, seamless, and comfortable-underfoot properties.

Commercial & Retail: Office buildings, showrooms, restrooms, and locker rooms gain a durable, attractive floor.

Education & Hospitality: Schools, universities, stadiums, and hotels appreciate its combination of durability and design flexibility.

Light Industrial & Logistics: Warehouses, distribution centers, and manufacturing areas require its resistance to abrasion and impact from wheeled traffic.

Specialized Environments: Clean rooms, pharmaceutical facilities, and laboratories rely on its non-porous, chemical-resistant surface.

Professional Installation Process

For optimal performance, installation must be performed by trained, approved contractors. The key steps include:

Surface Preparation (Most Critical): Concrete is abrasive-blasted to a CSP 1-3 profile (per ICRI 310.2R) to ensure a clean, sound, and profiled substrate for maximum adhesion.

Optional Primer/1st Basecoat: A coat of high-solids epoxy (Resuflor MPE) is applied to seal the concrete and minimize outgassing.

1st Broadcast – Decorative Quartz: Colored quartz is broadcast into the wet epoxy for texture and color.

2nd Basecoat & Broadcast – Decorative Flake: A second epoxy coat is applied, followed immediately by the broadcast of decorative vinyl flakes to create the signature mosaic look.

Grout Coat & Topcoat: After curing and removing loose aggregate, a UV-resistant epoxy (Resuflor UVE) is applied to fill voids and create a smooth, durable, and glossy topcoat surface.

Curing: The system requires proper cure time (typically 24-48 hours for light traffic, 7 days for full properties) under controlled temperature (65-90°F) and humidity conditions.

Our Commitment: KAIDA PAINT provides more than just products. We offer comprehensive technical support, from specification guidance and on-site inspection to contractor training, ensuring your flooring project is a success from prep to finish.

Fequently Asked Questions (FAQ)

Q: How does ResuShield™ Deco Flake DQF compare to standard epoxy flake systems?

A: The DQF system is a premium, four-layer construct using both quartz and flake aggregates. This provides greater texture, depth of design, and enhanced physical durability compared to simpler flake-in-topcoat systems.

Q: What is the typical lifespan and maintenance required?

A: With professional installation and proper care, the floor can last 15+ years in commercial settings. Maintenance is simple: regular sweeping/dust mopping and occasional damp mopping with pH-neutral cleaners. Avoid harsh abrasives and steel wool.

Q: Can it be installed over existing tile or damaged concrete?

A: It is designed for properly prepared concrete substrates. Existing coverings like tile must be removed. Cracked or spalled concrete requires repair prior to installation. Our technical team can advise on specific substrate conditions.

Q: What is the approximate cost per square foot?

A: The cost varies based on project size, condition of the existing concrete, chosen colors/flake density, and geographic location. Contact us for a detailed quote tailored to your project specifications.

KAIDA PAINT: Your Trusted Partner for High-Performance Flooring Solutions

Navigating the complex world of industrial coatings requires a partner with both manufacturing excellence and field-proven expertise. KAIDA PAINT stands as that partner. We are not just a supplier; we are problem-solvers dedicated to protecting your assets and enhancing your spaces with advanced flooring systems like ResuShield™.

Our advantage lies in a holistic approach:

Innovative Product Portfolio: We develop and manufacture robust coatings, including epoxy, polyurethane, and cementitious systems, tailored for specific challenges.

Technical Leadership: Our team provides unparalleled support in system specification, installation methodology, and troubleshooting, ensuring performance aligns with promise.

Quality & Consistency: Rigorous control from raw materials to finished products guarantees you receive a reliable, high-performing solution every time.

Global Reach, Local Service: We support contractors and companies worldwide, backed by a network of trained professionals and commercial teams.

Have a challenging flooring project? Let’s discuss how our ResuShield™ systems and our expertise can deliver the durability, safety, and aesthetics your facility demands. Contact our team of experts today for a consultation.

Stop compromising between durability and design. The ResuShield™ Deco Flake DQF epoxy flooring system offers the ultimate solution for your commercial or industrial space.

Contact KAIDA PAINT today for a free consultation, project quote, or to connect with a certified installer in your area. Let us help you specify the best, most cost-effective flooring for your facility.