الوصف

For contractors, facility managers, and companies seeking a high-performance flooring solution that combines extreme durability with underfoot comfort, look no further than the FlexTop™ SL urethane flooring system. This innovative, 1/8-inch thick, decorative elastomeric coating is engineered to solve the toughest challenges in industrial and commercial environments, offering a seamless, anti-slip polyurethane surface that stands up to heavy traffic, chemical spills, and mechanical abuse while providing ergonomic benefits. It’s more than just a paint or sealer; it’s a complete system designed for long-term performance.

نظرة عامة على المنتج

The FlexTop™ SL is a high-performance, decorative elastomeric urethane flooring system specifically designed for demanding industrial and commercial spaces. Through its unique polyurethane resin formulation, it creates a flexible, monolithic surface that bridges minor substrate cracks. The system possesses exceptional abrasion resistance, outstanding chemical tolerance, and innovative acoustic-dampening properties. It provides a durable, sanitary, and comfortable finish for facilities such as warehouses, manufacturing plants, laboratories, and healthcare centers, addressing both functional and ergonomic needs.

Common Industrial Flooring Pain Points & How FlexTop™ SL Solves Them

Industrial floors face relentless daily challenges that standard الإيبوكسي أو cement surfaces often fail to withstand:

Cracking & Impact Damage: Heavy loads and equipment cause cracks in rigid concrete and standard flooring. FlexTop™ SL’s elastomeric formulation allows it to flex and bridge hairline cracks, preventing them from telegraphing through the finish.

Chemical Corrosion & Stains: Spills from oils, greases, solvents, and cleaning agents degrade floors. Our polyurethane topcoat offers superior chemical resistance compared to many epoxy systems, ensuring easy cleanup and long-term integrity.

Poor Hygiene & Difficult Cleaning: Porous surfaces and grout lines harbor bacteria and dirt. The seamless nature of the FlexTop™ SL coating eliminates joints, creating a non-porous, sanitary surface that is exceptionally easy to clean and maintain.

Worker Discomfort & Noise: Hard floors contribute to fatigue and elevated ambient noise. The 1/8-inch thick, flexible layer of FlexTop™ SL provides underfoot cushioning and helps dampen room noise, enhancing occupant well-being.

Slippery Surfaces & Safety Hazards: Wet or oily floors pose slip risks. The system can be formulated with anti-slip aggregates to achieve desired slip resistance (R9-R11 ratings), supporting facility safety initiatives.

FlexTop™ SL System: Core Features & Benefits

The FlexTop™ SL urethane flooring system is defined by a suite of advanced features that deliver tangible benefits:

متانة لا مثيل لها:

Abrasion Resistance: Withstands heavy wheeled traffic and abrasion, significantly outlasting standard epoxy coatings.

مقاومة الصدمات: Absorbs impacts from dropped tools and equipment without cracking.

Flexibility & Crack Bridging: Its elastomeric core allows movement, bridging dynamic cracks in the concrete substrate.

مقاومة فائقة للمواد الكيميائية: The polyurethane topcoat provides excellent resistance to a wide range of chemicals, including oils, greases, dilute acids, and alkalis, making it ideal for industrial and pharmaceutical settings.

Enhanced Safety & Comfort:

Anti-Slip Options: Customizable slip resistance meets safety standards for various environments.

Ergonomic Cushioning: Reduces foot and leg fatigue for employees who stand for long periods.

Acoustic Dampening: Helps lower ambient noise levels, improving the work environment.

Hygienic & Easy Maintenance:

Seamless & Joint-Free: No grout lines or seams to trap dirt or moisture, promoting a sanitary surface.

Easy to Clean: Smooth surface allows for quick cleaning with standard industrial detergents.

Aesthetic Versatility: Available in a wide palette of standard and custom colors to suit any design scheme, from functional grays to brand-specific accents.

Sustainable & Low VOC: Formulated with bio-based content and low VOC emissions, contributing to healthier indoor air quality and environmental goals.

المواصفات والبيانات الفنية

The performance of the FlexTop™ SL system is backed by rigorous testing against recognized ASTM standards.

| الممتلكات | طريقة الاختبار | Value / Result | Notes |

|---|---|---|---|

| System Thickness | - | 125 mils (3.2 mm) | Total applied thickness |

| مقاومة التآكل | ASTM D4060 (Taber HTS) | ≤ 12 mg weight loss | Excellent wear resistance |

| Hardness (Shore A) | ASTM D2240 | 43-44 | Indicates flexible, resilient surface |

| الصلابة (Shore D) | ASTM D2240 | 12 | |

| قوة الشد | ASTM D2370 | ≥ 500 psi | High strength |

| Elongation at Break | ASTM D2370 | ≥ 200% | High elasticity for crack bridging |

| مقاومة الصدمات | ASTM D2794 | ≥ 270 in-lbs | High impact tolerance |

| وقت العلاج الكامل | - | 7 أيام | For full chemical resistance |

Ideal Applications

The FlexTop™ SL urethane flooring system is the best polyurethane for garage floors, industrial plants, and countless other demanding spaces:

Manufacturing & Warehousing: Handles heavy traffic, pallet jacks, and chemical exposure. The anti-slip properties enhance safety in industrial settings.

Commercial Kitchens & Food/Beverage Processing: Withstands thermal shock, grease, and frequent harsh cleaning. Its seamless finish meets stringent hygiene standards.

Pharmaceutical & Life Sciences: Provides a cleanable, chemical-resistant surface that is critical for GMP environments.

Automotive & Aircraft Hangars: Resists fluids like oil, fuel, and hydraulic fluid, while its durability handles heavy equipment and tools. A superior polyurethane garage floor coating.

Healthcare & Laboratories: Offers a quiet, comfortable underfoot feel for staff and meets hygiene needs with its seamless surface.

Schools & Public Institutions: Durable, safe (anti-slip), and easy to maintain in high-traffic corridors and spaces.

Professional Installation Process

Achieving the specified performance requires professional installation by certified contractors. KAIDA PAINT provides comprehensive technical support throughout the process.

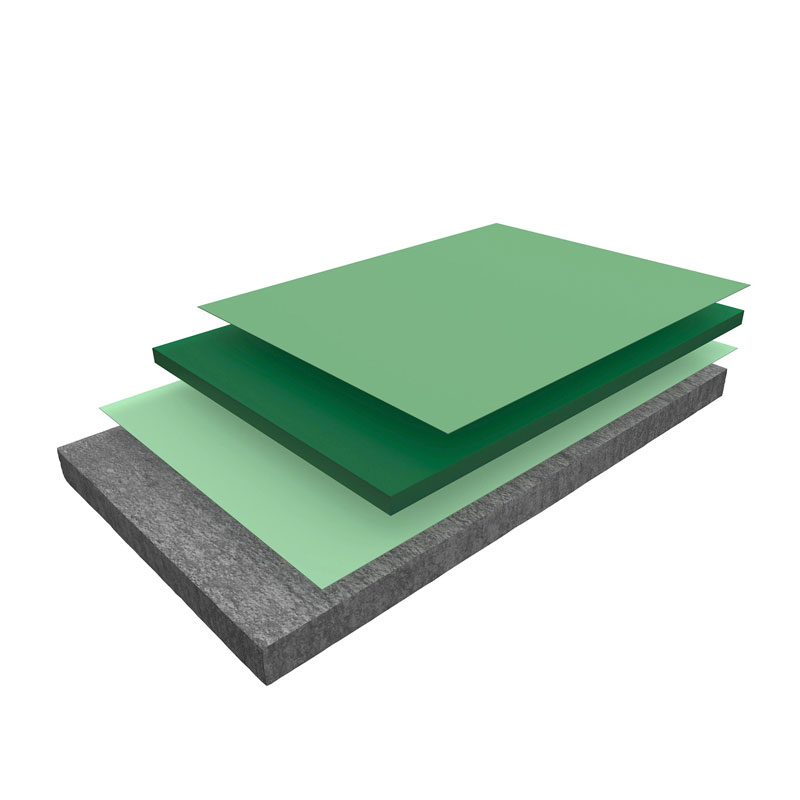

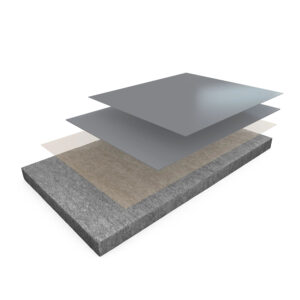

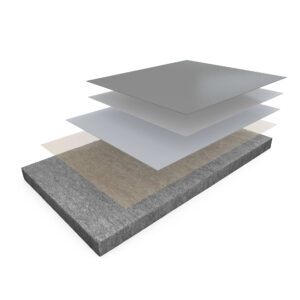

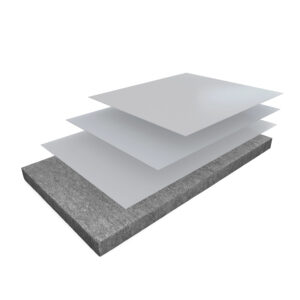

Substrate Assessment & Preparation: The concrete or cement base must be sound, clean, dry, and profiled (CSP 2-3 recommended). Proper mortar repairs are made if needed.

تطبيق التمهيدي: A dedicated primer ensures optimal adhesion to the substrate.

Intermediate Coat: The elastomeric FlexTop SLR Flex layer is applied at ~110 mils, providing the core thickness, flexibility, and comfort.

تطبيق الطلاء العلوي: The high-performance polyurethane topcoat (e.g., Resutile HTS 100) is applied, providing chemical resistance, abrasion resistance, and the desired finish (satin/gloss).

Curing & Protection: The system requires proper curing time (24 hours for light traffic, 7 days for full chemical resistance) before being put into full service.

الأسئلة الشائعة (FAQ)

Q1: What is the main difference between urethane (FlexTop SL) and epoxy flooring?

While both are resinous systems, urethane flooring like FlexTop SL is typically more flexible, offers better UV and chemical resistance, and has superior abrasion resistance. Epoxy can be more rigid and may yellow or chalk under UV exposure. Urethane is often the preferred topcoat over an epoxy basecoat or as a standalone system in high-traffic, chemical-rich industrial environments.

Q2: How long does it take to install a FlexTop SL urethane floor?

Installation time depends on area size, substrate condition, and system thickness. Typically, the primer, intermediate, and topcoat can be applied over 2-3 days. The floor can accept light traffic after 24 hours, but a full 7-day cure is required before exposure to heavy traffic or chemicals.

Q3: How do I maintain and clean a polyurethane floor coating?

Daily sweeping or dust mopping is recommended. For cleaning, use a mild, pH-neutral detergent and warm water. Avoid harsh acidic or abrasive cleaners. The seamless surface makes mopping and spill cleanup very easy. Periodic inspection and re-application of a maintenance topcoat can extend the floor’s life significantly.

Q4: What is the minimum temperature for applying FlexTop SL?

The concrete substrate and ambient temperature should be between 40°F (4°C) and 90°F (32°C) during installation, with the substrate at least 5°F above the dew point. Special procedures are required for application in cold or hot extremes.

Q5: Can FlexTop SL be applied over an existing epoxy floor?

It can be applied over some existing epoxy coatings, but this is highly condition-dependent. The existing coating must be fully adhered, sound, clean, and properly profiled (typically CSP 2-3). A thorough site assessment by a qualified contractor or our technical team is critical to determine suitability.

Q6: Is FlexTop SL suitable for exterior use?

The FlexTop SL system is primarily designed for interior use. For exterior concrete surfaces, we recommend consulting our technical team for products specifically formulated with enhanced UV stability and weather resistance.

Q7: What is the typical cost of a polyurethane floor coating like FlexTop SL?

The cost of a polyurethane flooring project varies based on the condition of the existing concrete slab, the size and complexity of the area, the chosen system thickness, and local labor rates. For an accurate quote tailored to your specific project, please contact us for a detailed assessment.

Q8: How do I choose a qualified installer for this system?

Successful installation is key to performance. We strongly recommend using contractors certified or approved by KAIDA PAINT. These installers have undergone specific training on our products and application procedures. Contact us for a referral to qualified installers in your region.

Proven Performance & Trust

FlexTop™ SL is specified by leading companies and contractors worldwide for critical flooring projects. Our systems are backed by detailed technical data sheets, chemical resistance guides, and the global support of KAIDA PAINT’s High Performance Flooring team. We partner with a network of certified, experienced installers to ensure every project meets the highest standards of quality and performance.

KAIDA PAINT: Your Trusted Partner in High-Performance Flooring Solutions

At KAIDA PAINT, we are more than just a manufacturer of industrial coatings; we are your dedicated partner in protecting assets and enhancing spaces. With decades of expertise in formulating advanced polyurethane, epoxy, and resin-based systems, we understand the critical demands of modern industrial, commercial, and institutional facilities. Our FlexTop™ SL urethane flooring system exemplifies this commitment—blending cutting-edge material science with practical, real-world performance.

Our advantage lies in a holistic approach:

Superior Product Technology: We invest in R&D to deliver products like FlexTop SL that offer genuine benefits—durability, safety, and comfort.

Unmatched Technical Support: Our team of experts provides specification guidance, chemical resistance analysis, and on-site support to ensure the right solution for your unique challenges.

Quality & Consistency: Rigorous manufacturing controls guarantee that every batch meets our high standards, giving contractors and end-users reliable performance.

Global Network, Local Support: We work with a certified network of professional installers worldwide, ensuring quality installation and customer satisfaction.

Whether you’re managing a global corporation’s facilities or overseeing a single warehouse project, choosing KAIDA PAINT means choosing a solution backed by science, service, and proven results.

Let’s discuss how the FlexTop™ SL system can transform your space. Contact our team for a detailed consultation and project specification today.

Get Your Custom Quote & Technical Support Today

Ready to upgrade your space with the durability and comfort of the FlexTop™ SL urethane flooring system? KAIDA PAINT is a leading manufacturer of high-performance industrial coatings, specializing in polyurethane, epoxy, and cementitious flooring solutions. We don’t just sell products; we deliver comprehensive solutions supported by expert specification services, on-site technical assistance, and a commitment to quality.

Contact our flooring experts today for:

A free project consultation and quote.

Detailed product data sheets and chemical resistance guides.

Assistance in selecting the right system for your specific needs.

Connection with our network of qualified installation contractors.