Описание

For facility managers, contractors, and project specifiers seeking a durable, high-performance flooring solution, the challenges are clear: concrete floors that crack, dust, stain, and degrade under heavy industrial use. The search for a system that combines the strength of cement with the flexibility and chemical resistance of urethane ends here. TerraFlex™ MC is a state-of-the-art cementitious urethane flooring system designed to deliver unparalleled longevity and performance in the toughest settings.

Product Overview: What is TerraFlex™ MC?

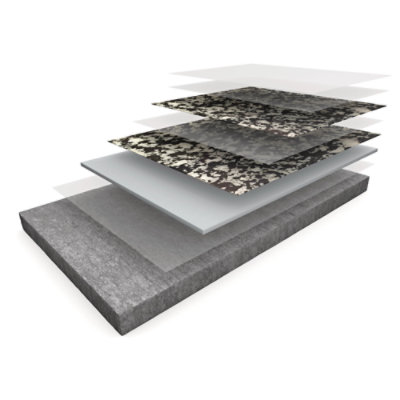

TerraFlex™ MC is a 100% solids, self-leveling hybrid flooring system with a nominal thickness of 1/8” to 3/16”. This advanced solution combines a rugged cementitious urethane base coat with rapid-curing, high-performance topcoats. The result is a seamless, decorative chip finish that offers exceptional resistance to abrasion, chemicals, and UV exposure. Engineered for industrial and commercial facilities where downtime is costly, it provides a durable, easy-to-clean, and aesthetically versatile coating that protects your concrete substrate for years to come.

The Industrial Flooring Challenge: Common Pain Points

Standard concrete floors and even some epoxy coating systems fall short under continuous stress. Key challenges include:

Mechanical Damage: Forklift traffic, dropped tools, and rolling loads cause cracks, chips, and pitting in standard mortar and concrete.

Химическая атака: Spills from oils, solvents, acids, and cleaning agents degrade many floor paint and sealer options, leading to stains and softening.

Moisture & Vapor Transmission: Sub-slab moisture can blister and delaminate impermeable flooring systems, a critical failure point.

Hygiene & Cleanliness: Porous surfaces harbor bacteria and are difficult to sanitize, a major concern for food processing and pharmaceutical companies.

Extended Downtime: Lengthy cure times for traditional coating systems disrupt operations and increase project cost.

The TerraFlex™ MC Solution: Core Features & Benefits

Unmatched Durability & Performance

Superior Abrasion & Impact Resistance: The cementitious urethane hybrid matrix withstands severe mechanical wear, far outperforming standard epoxy or polyurethane systems.

Exceptional Chemical Resistance: Highly resistant to a wide range of chemicals, including oils, greases, dilute acids, and alkalis, making it ideal for manufacturing plants and laboratories.

Moisture-Tolerant System: Can be installed over substrates with relative humidity up to 99%, mitigating risks associated with vapor drive—a game-changer for many installation scenarios.

Rapid Cure & Return-to-Service: Topcoats cure in as fast as 30-60 minutes, allowing for quick recoats and significantly reducing facility downtime.

Seamless & Hygienic Finish: A monolithic surface with no grout lines or seams prevents dirt accumulation and allows for easy, thorough cleaning.

UV & Thermal Stability: Resists yellowing and degradation from sunlight and can withstand significant thermal cycling, suitable for exterior applications and unheated spaces.

Aesthetic Flexibility & Safety

Decorative Chip Broadcast: Available in a wide array of standard and custom color blends to enhance facility aesthetics and branding.

Slip-Resistant Texture: The broadcast chip system provides a naturally textured surface that improves slip resistance, even when wet, contributing to a safer work environment.

Технические характеристики и данные

| Недвижимость | Метод испытания | Value / Result |

|---|---|---|

| Тип системы | - | 100% Solids, Cementitious Urethane Hybrid |

| Nominal Thickness | - | 1/8″ – 3/16″ (3-5 mm) |

| Прочность на сжатие | ASTM C 579 | > 8,300 psi |

| Прочность на разрыв | ASTM D 638 | > 3,550 psi |

| Устойчивость к истиранию | ASTM D 4060 | 21 mg loss (Taber) |

| Химическая стойкость | - | Excellent vs. Oils, Greases, Dilute Acids/Alkalis |

| Содержание летучих органических соединений | - | < 100 g/L (Topcoats); 0 g/L (Base) |

| Pot Life (@ 68°F/20°C) | - | 10-20 minutes |

| Cure Time (@ 68°F/20°C) | - | 30-60 minutes per coat |

| Moisture Tolerance | ASTM F 2170 | Up to 99% Relative Humidity |

Идеальное применение

The TerraFlex™ MC cementitious urethane flooring system is the solution of choice across diverse sectors:

Обработка продуктов питания и напитков: Stands up to chemical sanitizers, thermal shock, and heavy traffic while meeting hygiene standards.

Pharmaceutical & Laboratories: Provides a seamless, chemical-resistant, and easy-to-decontaminate surface.

Warehousing & Logistics: Withstands extreme abrasion from constant forklift and pallet jack traffic.

Automotive & Manufacturing: Resists oils, coolants, and impact from heavy equipment and tools.

Коммерческая и розничная торговля: Durable and attractive finish for supermarkets, restaurants, and schools.

Exterior Applications: Weather and UV-resistant properties make it suitable for certain outdoor areas.

Professional Installation & Support

A successful installation is paramount to performance. The TerraFlex™ MC system requires professional application by certified contractors.

Подготовка поверхности: Concrete must be shot-blasted to a CSP 3-4 profile, clean, sound, and dry.

Испытание на влажность: Critical evaluation using ASTM methods to ensure substrate compatibility.

Primer Application: Used on porous substrates to ensure optimal bond.

Base Coat & Chip Broadcast: Self-leveling cementitious urethane is applied and immediately broadcast with decorative chips.

Broadcast Coat: A resin coat locks in the chips and builds thickness.

Нанесение верхнего покрытия: One or two seal coats are applied for maximum chemical and abrasion resistance.

KAIDA PAINT provides comprehensive technical support, from specification and substrate evaluation to on-site guidance, ensuring your flooring project is executed flawlessly.

Часто задаваемые вопросы (FAQ)

What is the difference between a cementitious urethane and an epoxy flooring system?

Cementitious urethane systems like TerraFlex™ MC offer superior flexibility, thermal shock resistance, and moisture tolerance compared to most epoxies. They are less brittle, which helps bridge minor substrate cracks, and cure faster, reducing downtime.

How long does the TerraFlex™ MC installation process take?

While dependent on area size and conditions, the system features rapid cure times (30-60 mins per topcoat). A full installation over a properly prepared slab can often be completed within 2-3 days, with quick return-to-service.

Can this system be installed in cold or damp conditions?

Application requires air and substrate temperatures between 60°F and 85°F. However, its moisture tolerance allows installation over concrete with up to 99% relative humidity, addressing common damp slab challenges.

What maintenance does a TerraFlex™ MC floor require?

Maintenance is simple. Regular sweeping and occasional damp mopping with neutral pH cleaners are typically sufficient. The seamless, non-porous surface resists staining and is easy to keep clean.

Почему стоит выбрать KAIDA PAINT?

KAIDA PAINT is a leading innovator and manufacturer of advanced protective coatings and resinous flooring systems. We specialize in engineering durable solutions for the world’s most demanding industrial and commercial environments. Our TerraFlex™ MC cementitious urethane flooring system exemplifies this commitment, blending robust cement technology with high-performance urethane chemistry.

Our advantage lies in a holistic approach: superior products backed by deep technical expertise. We work directly with facility owners, specifiers, and contractors to ensure the right system is selected and correctly installed. From initial site assessment and moisture testing to installation guidance and ongoing support, the KAIDA PAINT team is dedicated to the long-term success of your project. We understand that your floor is a critical asset, and our goal is to maximize its performance and lifespan, providing outstanding value and peace of mind.

At KAIDA PAINT, we are more than just a manufacturer of high-performance coating products. We are your partner in infrastructure protection. With years of expertise in formulating and supporting advanced industrial flooring systems, we stand behind TerraFlex™ MC with:

Proven Formulation: Engineered for real-world industrial challenges.

Technical Expertise: Direct access to application specialists and engineers.

Quality Assurance: Consistent, reliable products manufactured to stringent standards.

Contractor Network: Connections to a vetted network of experienced installation professionals.

Our commitment is to provide a solution that not only meets but exceeds your expectations for durability, safety, and value, optimizing your total cost of ownership.

Don’t let an inadequate floor impact your operations, safety, or bottom line. Explore how the TerraFlex™ MC cementitious urethane flooring system can provide the long-term solution you need.

Contact KAIDA PAINT today for a detailed specification, technical data sheets, or to connect with a qualified contractor in your area. Let’s build a stronger foundation for your business.