Описание

Product Overview:

TerraFlex™ MB is a solid-color, 3/16″-1/4″ thick hybrid cementitious urethane flooring system designed for high-traffic industrial and commercial spaces. The system utilizes a patented blend of a cementitious urethane base coat and fast-curing, high-performance topcoats, reinforced with a broadcast of natural quartz aggregate for enhanced slip resistance. It delivers exceptional wear, chemical, and moisture resistance, with a rapid installation process that minimizes business interruption. This makes it the ideal coating for facilities requiring a tough, reliable, and long-lasting flooring solution.

The Industrial Flooring Problem: Common Pain Points

In the demanding world of industrial and commercial facilities, your flooring system is a critical solution for safety, productivity, and longevity. Ordinary concrete floors crack, dust, and deteriorate under heavy traffic, chemical spills, and thermal stress, leading to costly downtime and repairs. Companies and contractors need a flooring coating that goes beyond a simple layer of paint – they need a robust, monolithic finish that becomes part of the structure itself.

Enter TerraFlex™ MB, a state-of-the-art cementitious urethane flooring system. This advanced hybrid mortar combines the rugged strength of modified cement with the superior flexibility and chemical resilience of polyurethane. Designed as a solution for the toughest environments, it delivers a seamless, durable, and easy-to-clean surface that stands up to decades of abuse.

Facility managers, contractors, and business owners face constant challenges with their concrete floors:

Cracking and Spalling: Constant impact from forklifts and heavy equipment causes traditional concrete to crack and break apart.

Dusting: Unsealed or worn floors generate harmful dust, contaminating products, damaging machinery, and creating health hazards.

Химическая атака: Spills from oils, acids, solvents, and sanitizers degrade standard paint and epoxy coatings, leading to softening, discoloration, and failure.

Moisture and Vapor Issues: Sub-surface moisture (hydrostatic pressure) can cause blisters and delamination of non-breathable coatings.

Hygiene and Cleanliness: Porous surfaces harbor bacteria and are difficult to sanitize, a critical concern in food, pharmaceutical, and healthcare settings.

Excessive Downtime: Lengthy installation and cure times for traditional flooring systems disrupt operations for days or weeks.

The TerraFlex™ MB Solution: Engineered for Performance

TerraFlex™ MB directly addresses these pain points with a comprehensive solution. Here’s how its detailed characteristics deliver unparalleled value:

1. Unmatched Durability & Mechanical Performance

Extreme Wear Resistance: The urethane-enhanced matrix offers superior abrasion resistance, far outperforming standard epoxy or plain concrete. Ideal for high-traffic aisles, industrial warehouses, and loading docks.

High Impact & Point Load Resistance: The flexible polyurethane component absorbs shock, preventing cracking from dropped tools, pallet racks, and rolling loads.

Seamless, Monolithic Finish: Creates a joint-free surface that eliminates dirt traps, prevents moisture ingress at seams, and is incredibly easy to clean.

2. Superior Chemical & Environmental Resilience

Broad Chemical Resistance: Resists a wide array of chemicals including oils, greases, dilute acids and alkalis, salts, and many solvents commonly found in industrial plants, automotive shops, and food processing facilities.

Moisture Tolerance: Can be installed in environments with high moisture vapor transmission rates (up to 99% RH), making it suitable for slabs-on-grade without the constant risk of blistering.

Термическая стабильность: Maintains integrity across a wide temperature range, suitable for freezers, coolers, and outdoor patios.

3. Safety, Aesthetics, and Functionality

Slip-Resistant Surface: The integrated quartz aggregate broadcast provides a textured finish that enhances traction, meeting or exceeding ADA and OSHA guidelines for wet and dry conditions.

Hygienic & Easy Maintenance: The non-porous, seamless surface prevents bacterial growth and can be steam-cleaned or harshly scrubbed without damage.

Color & Design Options: Available in a range of standard and custom colors, allowing for aesthetic zoning, safety marking, and brand alignment.

4. Rapid, Efficient Installation

Fast-Cure Technology: Topcoats can cure in as little as 1 hour, allowing for multiple coats in a single day.

Reduced Downtime: The complete system can be installed and ready for light foot traffic in as few as 48 hours, getting your business back to full operation faster.

Professional Application: While a DIY paint job won’t suffice, our network of certified contractors ensures a flawless, warrantied installation.

Technical Specifications & Authority Data

TerraFlex™ MB is backed by rigorous third-party testing to international standards, ensuring performance you can trust.

| Недвижимость | Метод испытания | Typical Value | Benefit |

|---|---|---|---|

| Толщина системы | Номинальный | 3/16″ – 1/4″ (4.7 – 6.3 mm) | Durable, wear-layer thickness |

| Прочность на сжатие | ASTM C-109 | >8,300 psi (57 MPa) | Withstands extreme point loads |

| Прочность на разрыв | ASTM D-638 | >2,000 psi (14 MPa) | High internal cohesion |

| Прочность на изгиб | ASTM D-790 | >3,700 psi (25.5 MPa) | Resists bending and cracking |

| Bond Strength to Concrete | – | >400 psi (Substrate fails) | Becomes integral with the slab |

| Твердость | ASTM D-2240 (Shore D) | 88-92 | Tough yet slightly flexible |

| Устойчивость к истиранию | ASTM D-4060 (CS17 Wheel) | 21 mg loss | Extremely high wear life |

| Slip Resistance (Wet) | ANSI A326.3 | >0.42 Dynamic Coefficient | Safer wet traction |

| Поглощение воды | ASTM D-570 | 0.04% | Highly impervious |

| Содержание летучих органических соединений | – | <100 г/л | Lower environmental impact |

Ideal Application Areas

TerraFlex™ MB is the specified flooring solution across diverse sectors:

Обработка продуктов питания и напитков: Withstands thermal shock, harsh sanitizers, and provides a USDA/FDA-compliant cleanable surface.

Warehousing & Logistics: Resists abrasion from constant forklift traffic and impact from falling goods.

Pharmaceutical & Life Sciences: Offers a seamless, non-shedding, and chemical-resistant floor for cleanrooms and labs.

Automotive & Manufacturing: Handles chemical spills, hot tire pickup, and heavy equipment.

Commercial & Institutional: Ideal for school corridors, hospital kitchens, airport concourses, and retail backrooms due to its durability and safety.

Parking Decks & Outdoor Walkways: UV-stable and weather-resistant for exterior applications.

Professional Installation & Technical Support

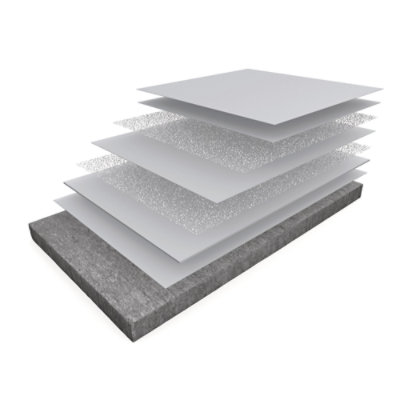

A successful installation relies on proper surface preparation and expert application. The TerraFlex™ MB process, typically handled by our network of professional contractors, includes:

Substrate Evaluation & Preparation: Critical moisture testing and mechanical profiling (e.g., shot blasting to CSP 3-4) ensure optimal adhesion.

Primer Application: On porous substrates, a primer ensures a solid bond.

Base Coat & Broadcast: The cementitious urethane mortar is applied and broadcast with quartz aggregate for reinforcement and texture.

Sealer/Topcoat Application: Multiple layers of high-performance, chemical-resistant topcoats are applied to seal the surface and provide the final wear layer.

Curing & Protection: Proper cure times are observed before returning to service.

We provide more than just products. Our technical support team assists with site audits, specification writing, and contractor training to ensure your project’s success from start to finish.

Часто задаваемые вопросы (FAQ)

What is the difference between a cementitious urethane and an epoxy flooring system?

While both are durable, cementitious urethane systems like TerraFlex™ MB offer superior flexibility, thermal shock resistance, and moisture tolerance. They are less brittle than epoxy, making them better for environments with active cracks or wide temperature swings. Epoxy can be harder but is more prone to chipping under impact.

How long does it take to install TerraFlex™ MB?

The system is designed for rapid installation. Under ideal conditions, the floor can be installed and ready for light foot traffic in 2 days, with full cure and return to heavy service shortly after, minimizing facility downtime.

Can TerraFlex™ MB be installed over existing concrete?

Yes, it is an excellent solution for concrete renovation. The existing slab must be properly prepared, sound, and pass moisture tests. It can also be installed over properly prepared waterproof membranes.

What maintenance is required?

Maintenance is simple. Regular sweeping and occasional damp mopping with a neutral pH cleaner are typically sufficient. The seamless surface eliminates grout lines and pits where dirt accumulates.

What is the typical cost of a cementitious urethane flooring system?

The total project cost varies based on slab condition, project size, preparation needed, and geographic location. As a premium, long-life system, it represents a significant value investment over its lifespan compared to frequent repairs or replacement of inferior flooring. Contact us for a site-specific quote.

Trust Built on Proven Performance

TerraFlex™ MB isn’t just a product; it’s a specification trusted by leading companies globally. Our system is specified for projects requiring compliance with USDA, FDA, and stringent indoor air quality standards (like CA Section 01350). We partner with elite contractors who are trained in our specific application protocols to deliver consistent, high-quality results. View our project gallery for pictures of successful installations in facilities just like yours.

Choose KAIDA PAINT as Your Flooring Solutions Partner

At KAIDA PAINT, we are more than a manufacturer; we are your dedicated partner in building resilient, high-performance facilities. With years of expertise in advanced polymer coatings, we develop products like the TerraFlex™ MB cementitious urethane flooring system to solve real-world industrial challenges. Our commitment extends beyond the sale through unparalleled technical support, specification assistance, and a network of certified applicators. We ensure your flooring investment delivers maximum return through longevity, safety, and performance.

For over 15 years, KAIDA PAINT has been at the forefront of advanced protective coating technologies. We specialize in engineering high-performance flooring solutions for the world’s most demanding environments. Unlike standard paint companies, we focus on integral system performance—from substrate to finish. Our TerraFlex™ MB cementitious urethane formulation is a testament to this commitment, blending raw material science with practical application wisdom. We partner directly with facility owners, specifiers, and expert contractors to ensure every project achieves its longevity and performance goals.

Ready to transform your concrete floors into a lasting asset?

Contact KAIDA PAINT today for a free consultation, technical data sheet, or a quote tailored to your specific project needs. Let our experts help you specify the right solution for your facility.