Описание

Обзор продукции

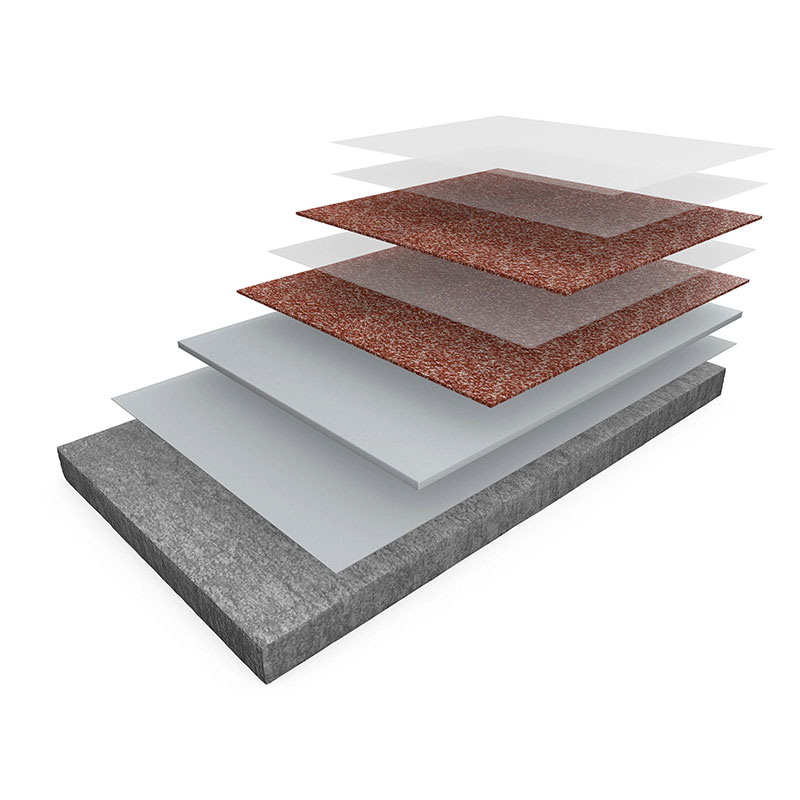

The ResuShield™ XT Deco Quartz DB is a state-of-the-art, moisture-tolerant epoxy quartz flooring system. Designed specifically for slabs on grade known or suspected to have vapor emission issues, it combines a robust epoxy resin matrix with graded quartz aggregates to create an integrally protected, monolithic surface. This system delivers exceptional resistance to wear, chemicals, and impacts, while offering limitless aesthetic color blend options in a satin finish. It provides a seamless, slip-resistant, and hygienic flooring solution for demanding commercial and industrial environments, eliminating the need for costly moisture testing and mitigating the risk of bond failure.

The Industrial Flooring Challenge: Common Pain Points

Why do standard floors fail in demanding settings? Here are the core issues our clients face:

Moisture & Bond Failure: Sub-surface moisture vapor pressure can blister and delaminate standard epoxy coatings, causing complete system failure.

Химическая коррозия: Spills from oils, greases, solvents, and cleaning agents degrade floor surfaces, leading to stains, softening, and contamination.

Mechanical Wear & Tear: Constant traffic from forklifts, heavy carts, and dropped tools causes abrasion, chipping, and dusting of concrete.

Hygiene & Safety Concerns: Porous surfaces harbor bacteria, while smooth, wet floors become slip hazards. Maintaining a clean, sanitizable surface is critical in food, pharmaceutical, and healthcare applications.

Aesthetic Degradation: Fading, yellowing, and a worn-out appearance negatively impact the professional image of a facility.

The ResuShield™ XT Solution: Detailed Product Features

Our epoxy flooring system is engineered as a comprehensive solution to these universal problems.

Unmatched Mechanical Durability

Extreme Wear Resistance: With an abrasion loss of only 70-90 mg per 1,000 cycles (ASTM D4060), it far outlasts standard industrial paint and coating.

High Strength: Features a compressive strength of 12,000 psi and a tensile strength of 6,000 psi (ASTM standards), ensuring it can handle heavy, sustained loads without cracking.

Superior Adhesion: Bonds to properly prepared concrete with a strength greater than 300 psi, resulting in concrete failure before coating delamination.

Proven Chemical & Stain Resistance

The topcoat is formulated to withstand a wide range of industrial chemicals, making it ideal for warehouses, kitchens, labs, and manufacturing plants. It is resistant to most common acids, alkalis, solvents, and oils, facilitating easy cleaning and maintenance.

Integral Moisture Vapor Protection

The core innovation of the ResuShield™ XT Deco Quartz DB system. Its specialized formulation and application method provide intrinsic protection against vapor transmission, making it the best choice for basements, on-grade slabs, and areas with potential moisture issues—no separate moisture mitigation layer or testing needed.

Safety & Aesthetic Flexibility

Slip-Resistant Finish: The textured quartz surface provides a safe, slip-inhibiting finish even when wet, meeting safety standards for shower rooms, kitchens, and pool decks.

Limitless Design: Choose from unlimited standard and custom color blends. Achieve decorative effects with quartz flakes that can mimic terrazzo, marble, or stone.

Satin Sheen: Offers a professional, low-glare finish that hides imperfections and reduces light reflection, suitable for commercial and industrial settings.

Технические характеристики и данные

The following table summarizes the key physical properties of the ResuShield™ XT system, based on standardized ASTM testing methods.

| Недвижимость | Метод испытания | Результат |

|---|---|---|

| Твердость | ASTM D2240 (Shore D) @ 24 hrs | 70 / 65 |

| Прочность на сжатие | ASTM C579 | 12,000 psi |

| Прочность на разрыв | ASTM D638 | 6,000 psi |

| Adhesion to Concrete | ACI 503R | >300 psi (Concrete Failure) |

| Устойчивость к истиранию | ASTM D4060 (CS-17 Wheel, 1000 cycles) | 70-90 mg lost |

| Прочность на изгиб | ASTM D790 | 10,000 psi |

Идеальное применение

This versatile system is specified by leading companies across diverse sectors:

Еда и напитки: USDA-accepted for commercial kitchens, processing plants, and packaging areas. Resists stains, fats, and harsh cleaning solutions.

Pharmaceutical & Laboratories: Provides a seamless, non-porous, and chemical-resistant surface for clean rooms and labs.

Логистика и складское хозяйство: Withstands extreme abrasion from pallet jacks and forklifts in warehouse and storage areas.

Automotive & Manufacturing: Handles oil, grease, and chemical spills in repair bays and plants.

Институциональный: Durable and easy to clean for schools, hospitals, locker rooms, and bathrooms.

Коммерческая и розничная торговля: Attractive, durable flooring for showrooms, restaurants, and public spaces.

Professional Installation Process

Optimal performance requires professional installation by approved contractors. Our system ensures a reliable result through a meticulous process:

Surface Preparation (Prep): Concrete is abrasive-blasted to a CSP 4-6 profile to ensure a clean, sound, and porous substrate.

Primer Application: A moisture-tolerant epoxy primer is applied to seal the slab and promote adhesion.

Slurry & Broadcast Coat: A thick epoxy slurry coat is troweled on and immediately broadcast with colored quartz aggregate to a minimum 1/8″ thickness.

Bonding & Second Broadcast: A bonding coat is applied and broadcast with more quartz for density and texture.

Grout & Seal Coats: Epoxy grout fills the quartz matrix, followed by a final protective seal coat to provide chemical resistance and a uniform finish.

Затвердевание: The system requires proper cure time (typically 24-72 hours) before subjecting to full service.

We provide comprehensive technical support, from specification and prep guidance to on-site consultation, ensuring your contractor achieves a flawless installation.

Часто задаваемые вопросы (FAQ)

Q1: Does the ResuShield™ XT system require a moisture vapor test before installation?

A: No. A key benefit of the ResuShield™ XT Deco Quartz DB epoxy flooring system is its integral resistance to moisture vapor transmission. It is specifically engineered for slabs on grade where moisture may be present, eliminating the time and cost of pre-installation moisture testing.

Q2: How long does the installation and curing process take?

A: The multi-coat installation typically requires 3-4 days for application. Each coat has specific cure times (e.g., 18-24 hours). The full system requires 2-3 days of curing after the final seal coat before exposure to heavy traffic or chemical washdown for optimal performance.

Q3: Can this flooring be installed over existing tile or old epoxy?

A: It is primarily designed for installation over properly prepared, sound Portland cement concrete. Installation over other substrates like ceramic tile or existing coatings requires rigorous assessment, surface profiling, and often involves mechanical removal to ensure a proper bond. Consult our technical team for a project-specific evaluation.

Q4: How do I clean and maintain this epoxy flooring?

A: Daily maintenance is simple: dust mop or use a vacuum. Remove spills promptly with a damp mop. For periodic deep cleaning of textured surfaces, use a bristle brush (not a nylon pad) with a mild, pH-neutral detergent, then rinse and wet vacuum. Avoid harsh acids, abrasive cleaners, and steel wool. We provide a complete maintenance guide upon project completion.

Q5: What is the difference between this and a standard epoxy floor coating?

A: The ResuShield™ XT system is a high-build, aggregate-reinforced system (minimum 1/8″ thick), not a thin film coating. Its primary differentiators are: 1) Integral moisture vapor protection, 2) Exceptional thickness and durability from quartz aggregate, 3) A textured, slip-resistant finish, and 4) A multi-layer, broadcast system that provides superior mechanical strength compared to standard self-leveling or paint-grade epoxies.

Q6: Is this flooring system slippery when wet?

A: No. The textured surface created by the broadcast quartz aggregate provides a slip-inhibiting finish, making it suitable for areas like commercial kitchens, locker rooms, showers, and pool decks where water or spills are common.

Q7: What is the typical cost per square foot for this system?

A: The total installed cost varies based on project size, site conditions, substrate preparation requirements, and geographic location. As a professional-grade, multi-layer system, it is an investment in long-term performance. For an accurate quote tailored to your specific project, please contact us for a detailed estimate.

Q8: Does it come with a warranty?

A: Yes. We warrant our products to be free from manufacturing defects. The ultimate performance and longevity of the installed system depend heavily on correct substrate preparation and professional installation by approved contractors. Specific warranty details are provided with the product.

Why Choose Our Professional Flooring Solutions?

We are more than a manufacturer; we are your technical partner. Our company brings deep industry expertise, authoritative product knowledge, and a commitment to your project’s success. We support contractors and end-users with:

Expert Specification Service: Helping you select the right system for your specific chemical and physical demands.

Unmatched Technical Support: On-call assistance from application to repair.

Quality Assurance: All products are manufactured under strict quality controls, ensuring consistent performance batch after batch.

Готовы ли вы преобразить свой пол?

Stop compromising on your industrial or commercial flooring. The ResuShield™ XT Deco Quartz DB epoxy flooring system offers a proven, high-performance solution that addresses moisture, durability, and safety concerns head-on.

Contact our flooring experts today for a detailed quote, technical data sheets, or to discuss your specific project needs. Let us help you install a floor that stands the test of time.

KAIDA PAINT: Your Trusted Partner in High-Performance Flooring

At KAIDA PAINT, we specialize in formulating and supplying advanced industrial coating solutions for the most demanding environments. As both a leading manufacturer and a supporter of professional contractors, we understand the critical balance between product performance, application practicality, and total project cost. Our ResuShield™ line, including the XT Deco Quartz DB system, embodies our commitment to innovation solving pervasive industry problems like moisture vapor. We back our products with rigorous R&D, comprehensive technical support, and a network of trained installers. Partner with KAIDA PAINT for a flooring solution that delivers not just a coating, but long-term value, safety, and performance for your business.